Preparation method of novel environmentally-friendly energy-saving gypsum board

An environmental protection and energy saving, gypsum board technology, applied in the field of building gypsum board, can solve the problems of not obvious effect, poor flame retardant and hydrophobicity, poor thermal insulation effect, etc., to improve indoor living or working environment, good flame retardant and fire resistance , the effect of reducing electromagnetic interference and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to a new type of environmentally friendly and energy-saving gypsum board, which is composed of the following raw materials in parts by weight:

[0040] 56 parts of modified citric acid waste residue gypsum;

[0041] Wudalianchi volcanic mud 23 parts;

[0042] 10 parts of rectorite powder;

[0043] Six ring stone powder 10 parts;

[0044] 4 parts hollyhock fiber;

[0045] 1 part of ferric chloride;

[0046] 2.5 parts of chlorogenic acid;

[0047] 6 parts coumarone resin;

[0048] 3 parts of compound latex powder;

[0049] 1.5 parts of compound coupling agent;

[0050] Compound air-entraining agent 2 parts.

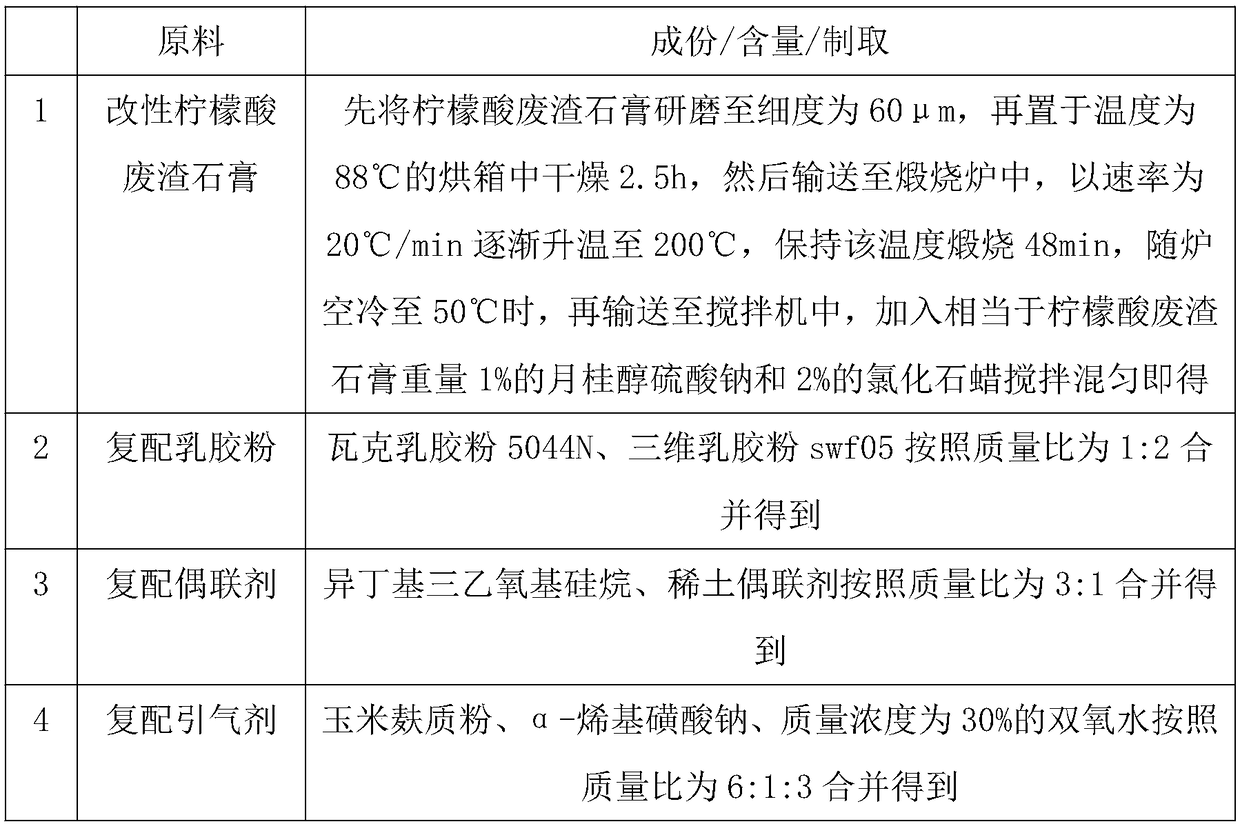

[0051] The selection and production of modified citric acid waste residue gypsum, compound latex powder, compound coupling agent and compound air-entraining agent in this embodiment are shown in Table 1 below:

[0052] Table 1

[0053]

[0054] The preparation method of gypsum board generally carries out according to the following...

Embodiment 2

[0060] This embodiment relates to a new type of environmentally friendly and energy-saving gypsum board, which is composed of the following raw materials in parts by weight:

[0061] 62 parts of modified citric acid waste residue gypsum;

[0062] Wudalianchi volcanic mud 27 parts;

[0063] 14 parts of rectorite powder;

[0064] 14 parts of hexacyclic stone powder;

[0065] 4.5 parts of hollyhock fiber;

[0066] 1.2 parts of ferric chloride;

[0067] 2.7 parts of chlorogenic acid;

[0068] 6.5 parts of coumarone resin;

[0069] 3.5 parts of compound latex powder;

[0070] 1.8 parts of compound coupling agent;

[0071] Compound air-entraining agent 2.5 parts.

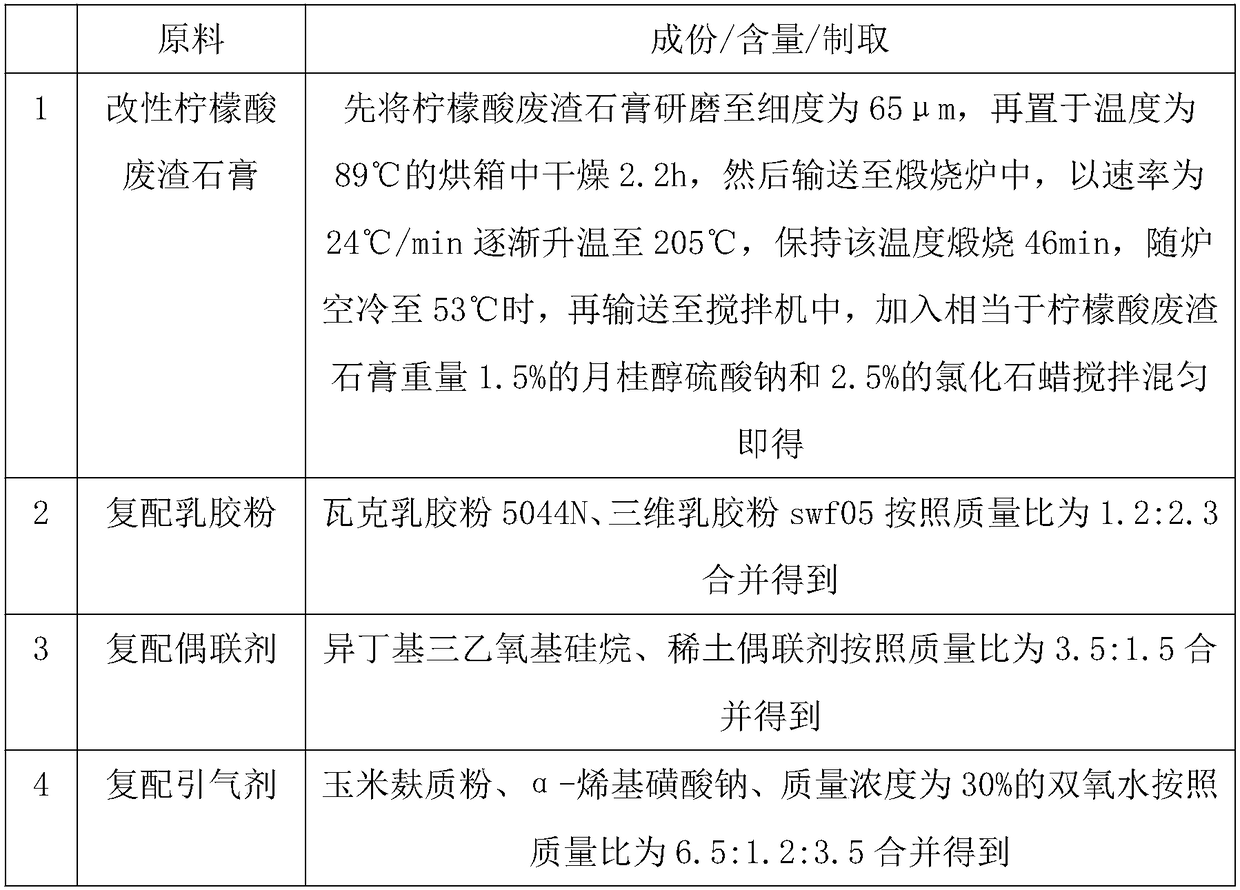

[0072] The selection and production of modified citric acid waste residue gypsum, compound latex powder, compound coupling agent and compound air-entraining agent in this embodiment are shown in Table 2 below:

[0073] Table 2

[0074]

[0075] The preparation method of gypsum board generally carries out acco...

Embodiment 3

[0081] This embodiment relates to a new type of environmentally friendly and energy-saving gypsum board, which is composed of the following raw materials in parts by weight:

[0082] 64 parts of modified citric acid waste residue gypsum;

[0083] Wudalianchi volcanic mud 29 parts;

[0084] 15 parts of rectorite powder;

[0085] Six ring stone powder 15 parts;

[0086] 5 parts hollyhock fiber;

[0087] 1.5 parts of ferric chloride;

[0088] 3 parts of chlorogenic acid;

[0089] 7 parts of coumarone resin;

[0090] 4 parts of compound latex powder;

[0091] 2 parts of compound coupling agent;

[0092] 2.8 parts of compound air-entraining agent.

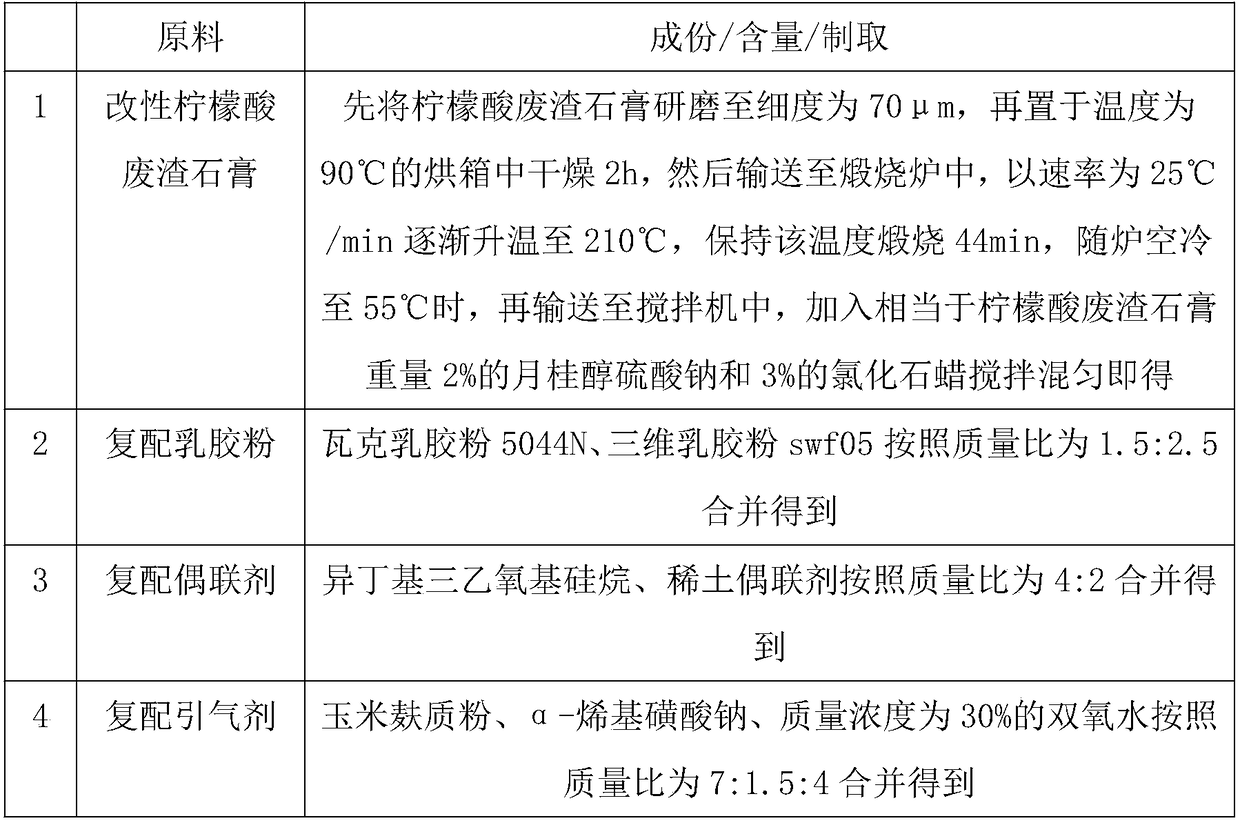

[0093] The selection and production of modified citric acid waste residue gypsum, compound latex powder, compound coupling agent and compound air-entraining agent in this embodiment are shown in Table 3 below:

[0094] table 3

[0095]

[0096] The preparation method of gypsum board generally carries out according to the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com