Nano zinc oxide modified foaming material and preparation method thereof

A technology of nano-zinc oxide and foaming materials, which is applied in the field of chemical materials, can solve the problems of lack of preparation methods for nano-zinc oxide modified foaming materials, etc., and achieve the effects of excellent comprehensive mechanical properties, improved dielectric constant, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

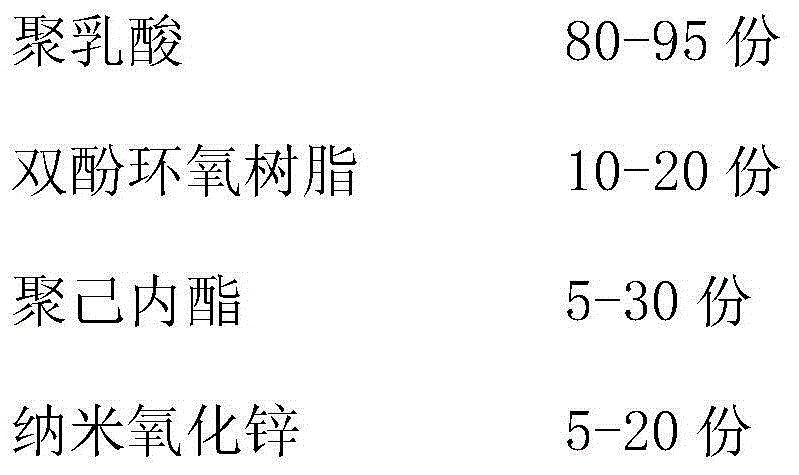

[0038] The present invention of the present invention provides a kind of nano-zinc oxide modified foaming material, is made up of the component that comprises following parts by weight:

[0039]

[0040]

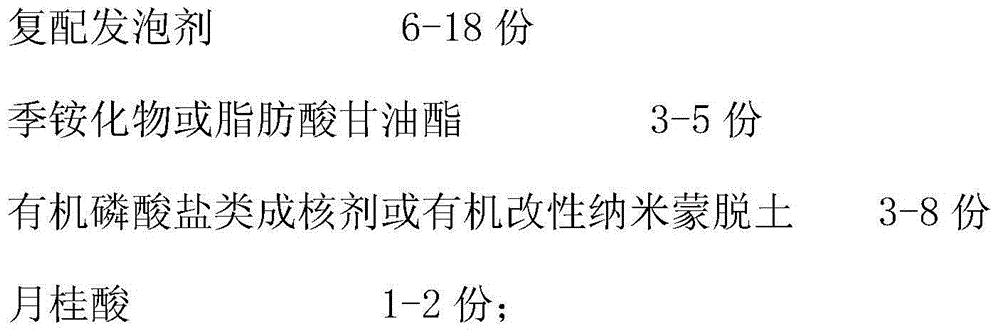

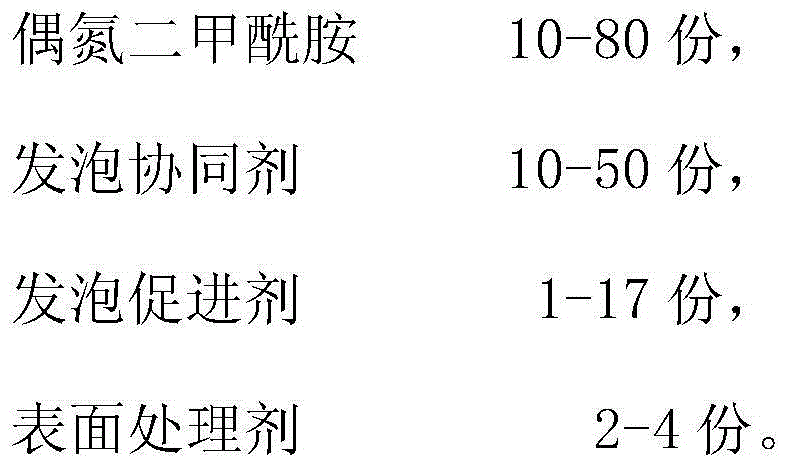

[0041] Described compound blowing agent is made up of the component that comprises following parts by weight:

[0042]

[0043] The polylactic acid is a matrix resin, the nano zinc oxide is a conductive material, and the flexible and biodegradable polycaprolactone is a toughening agent.

[0044] The foam accelerator is dibutyltin dilaurate.

[0045] The weight average molecular weight of the polycaprolactone is 60,000. The models of the polylactic acid are 4032D and 2002D, and the mass ratio of the two is 1:1.

[0046] The preparation method of nano-zinc oxide modified foam material of the present invention, comprises the steps:

[0047] (1) Weigh each component in the above ratio, mix them thoroughly in a high-speed blender according to the ratio, and dry them f...

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 is: the present invention of the present invention provides a kind of nano-zinc oxide modified foaming material, is made up of the component that comprises following parts by weight:

[0059]

[0060]

[0061] Described compound blowing agent is made up of the component that comprises following parts by weight:

[0062]

[0063] The foam accelerator is a combination of dibutyltin maleate and di(n-octyl)tin maleate.

[0064] The weight average molecular weight of the polycaprolactone is 70,000.

[0065] The preparation method of nano-zinc oxide modified foam material of the present invention, comprises the steps:

[0066] (1) Weigh each component in the above ratio, mix them thoroughly in a high-speed blender according to the ratio, and dry them for later use; the drying time for the raw materials is 17 hours.

[0067] (2) Extrude and granulate the uniformly mixed raw materials at a temperature of 150° C. us...

Embodiment 3

[0071] The difference between embodiment 3 and embodiment 1 is: the present invention of the present invention provides a kind of nanometer zinc oxide modified foaming material, is made up of the component that comprises following parts by weight:

[0072]

[0073] Described compound blowing agent is made up of the component that comprises following parts by weight:

[0074]

[0075] The polylactic acid is a matrix resin, the nano zinc oxide is a conductive material, and the flexible and biodegradable polycaprolactone is a toughening agent.

[0076] The foam accelerator is dibutyltin maleate.

[0077] The weight average molecular weight of the polycaprolactone is 90,000.

[0078] The preparation method of nano-zinc oxide modified foam material of the present invention, comprises the steps:

[0079] (1) Weigh the components in the above proportions, mix them thoroughly in a high-speed blender according to the ratio, and dry them for later use; the drying time for the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com