Shielding type FRTP material for wind power generation cover

A shielding and cover technology, which is applied in the field of shielding FRTP materials for wind power generation covers, can solve the problems of poor mechanical strength, low tensile strength, and difficulty in meeting actual needs, and achieves stable structure and size and good flame retardancy. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This embodiment relates to a shielding type FRTP material for a wind power generation cover. This FRTP material is composed of the following raw materials in parts by weight:

[0087] 47 parts of phenolphthalein side group polyether ketone;

[0088] 20 parts of bisphenol A polysulfone;

[0089] 16 parts of polyarylethynyl;

[0090] 8 parts of furfural resin;

[0091] 2 parts calcium silicate hydrate;

[0093] Moso bamboo fiber 25 parts;

[0094] 5 parts of palygorskite powder;

[0095] 1.5 parts of cage polysilsesquioxane;

[0096] 1 part of coupling agent;

[0097] 1 part of compatibilizer;

[0098] 0.3 part of antioxidant;

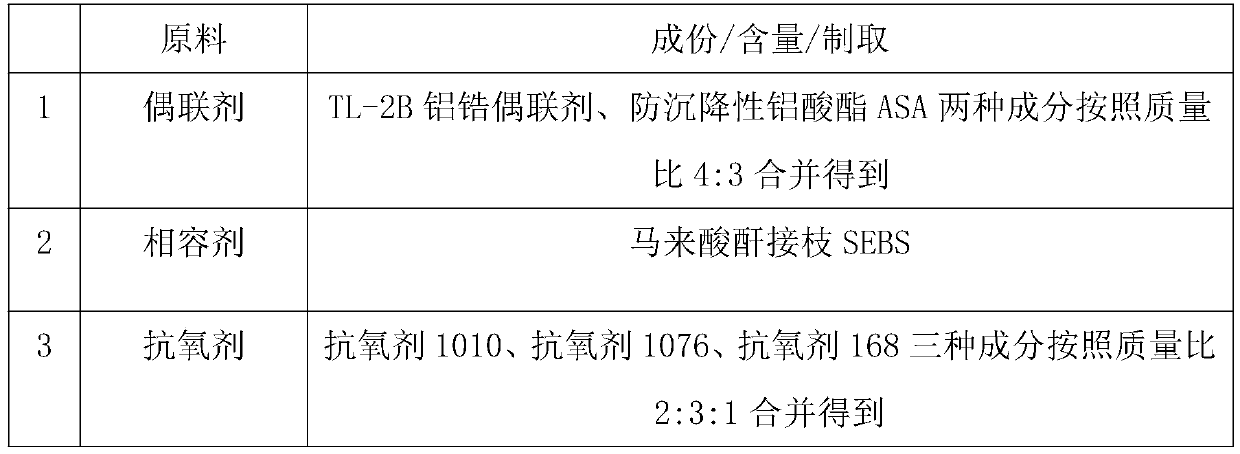

[0099] The selection and preparation of coupling agent, compatibilizer and antioxidant in the present embodiment are shown in Table 1 below:

[0100] Table 1

[0101]

[0102] The preparation method of FRTP material generally carries out according to the following steps in the present embodiment:

[0...

Embodiment 2

[0108] This embodiment relates to a shielding type FRTP material for a wind power generation cover. This FRTP material is composed of the following raw materials in parts by weight:

[0109] 50 parts of phenolphthalein side group polyether ketone;

[0110] 25 parts of bisphenol A polysulfone;

[0111] 18 parts of polyarylethynyl;

[0112] 10 parts of furfural resin;

[0113] 4 parts calcium silicate hydrate;

[0115] 27 parts of moso bamboo fiber;

[0116] 6 parts of palygorskite powder;

[0117] 2 parts of cage polysilsesquioxane;

[0118] 1.5 parts of coupling agent;

[0119] 1.2 parts of compatibilizer;

[0120] 0.5 part of antioxidant;

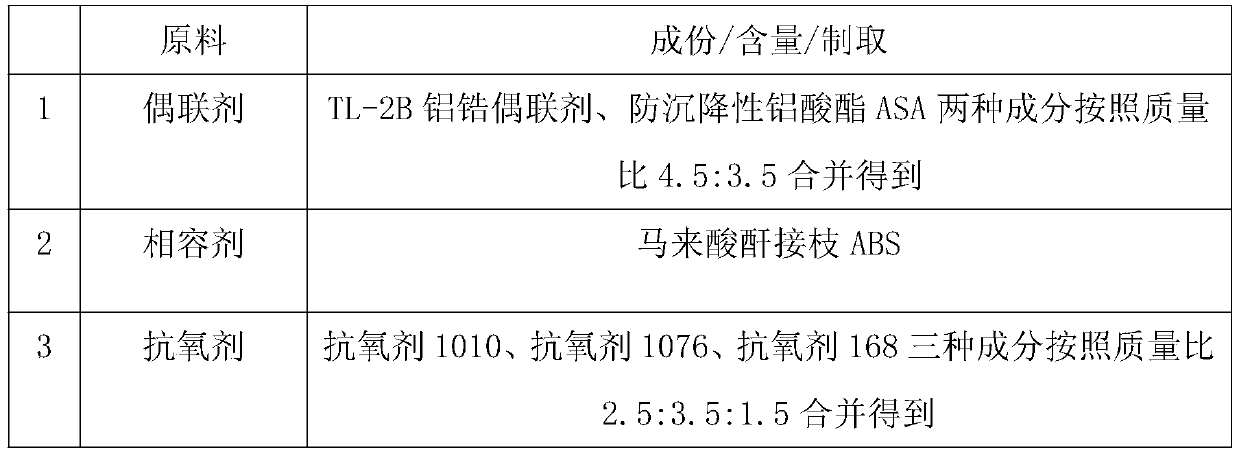

[0121] The selection and preparation of coupling agent, compatibilizer and antioxidant in the present embodiment are shown in Table 2 below:

[0122] Table 2

[0123]

[0124] The preparation method of FRTP material generally carries out according to the following steps in the present embodimen...

Embodiment 3

[0130] This embodiment relates to a shielding type FRTP material for a wind power generation cover. This FRTP material is composed of the following raw materials in parts by weight:

[0131] 54 parts of phenolphthalein side group polyether ketone;

[0132] 28 parts of bisphenol A polysulfone;

[0133] 21 parts of polyarylethynyl;

[0134] 12 parts of furfural resin;

[0135] 6 parts of calcium silicate hydrate;

[0136] Kevlar fiber 25 parts;

[0137] Moso bamboo fiber 29 parts;

[0138] 8 parts of palygorskite powder;

[0139] 3 parts of cage polysilsesquioxane;

[0140] 2 parts of coupling agent;

[0141] 1.5 parts of compatibilizer;

[0142] 0.7 part of antioxidant;

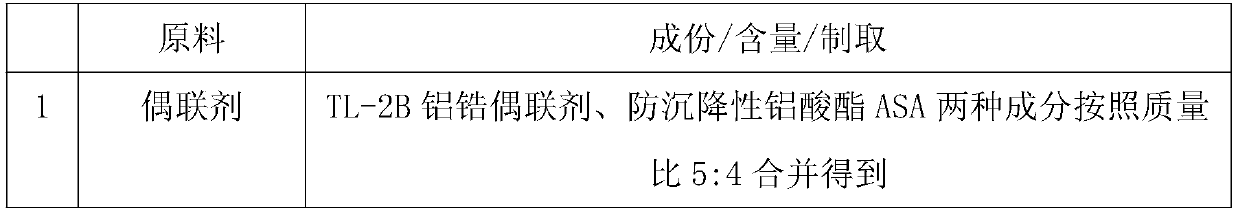

[0143] The selection and preparation of coupling agent, compatibilizer and antioxidant in the present embodiment are shown in Table 3 below:

[0144] table 3

[0145]

[0146]

[0147] The preparation method of FRTP material generally carries out according to the following steps in the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com