Fabric with eyed structures and weaving process thereof

A technology of mesh structure and fabric, applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems of difficult promotion, complicated weaving process, high production cost, etc., and achieve the effect of easy promotion, simple weaving process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

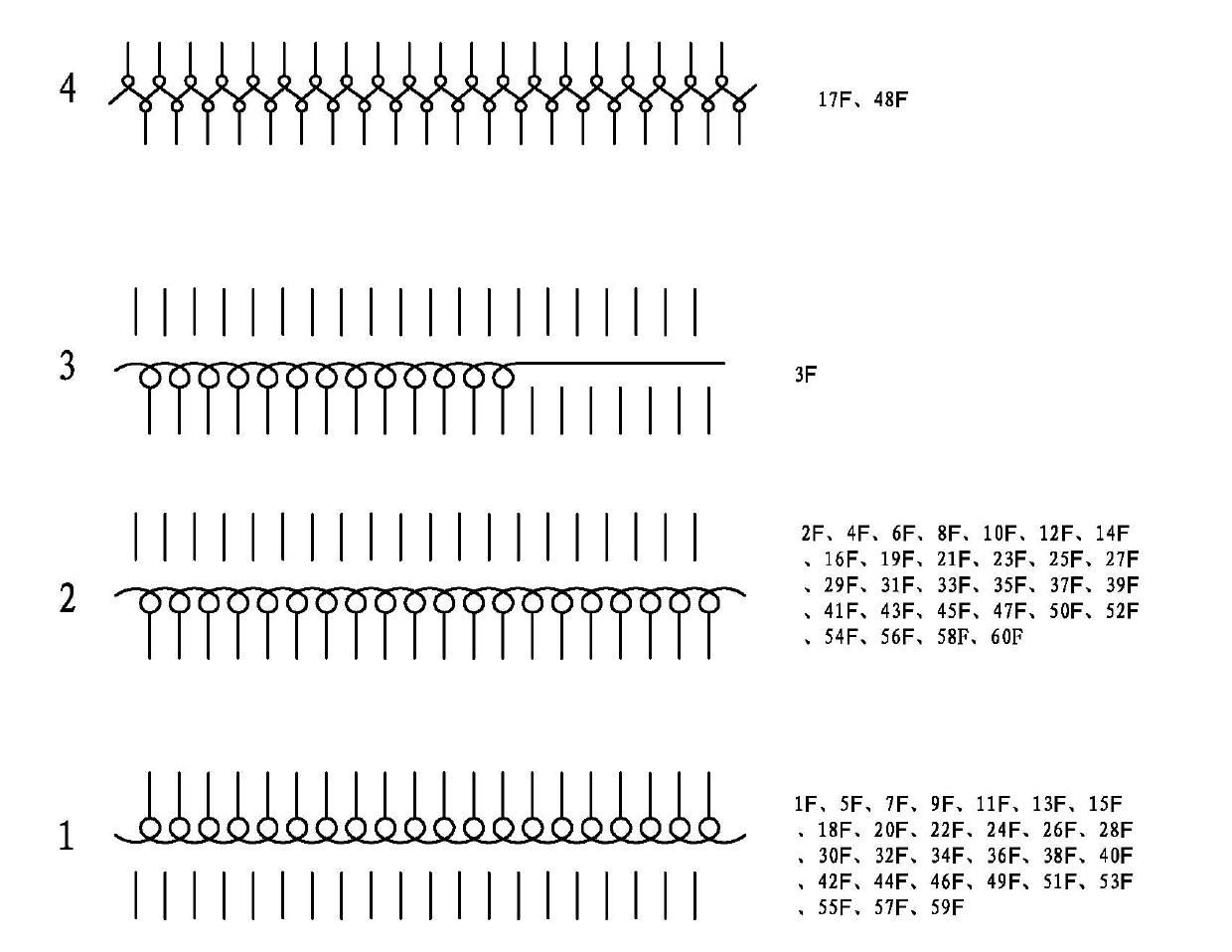

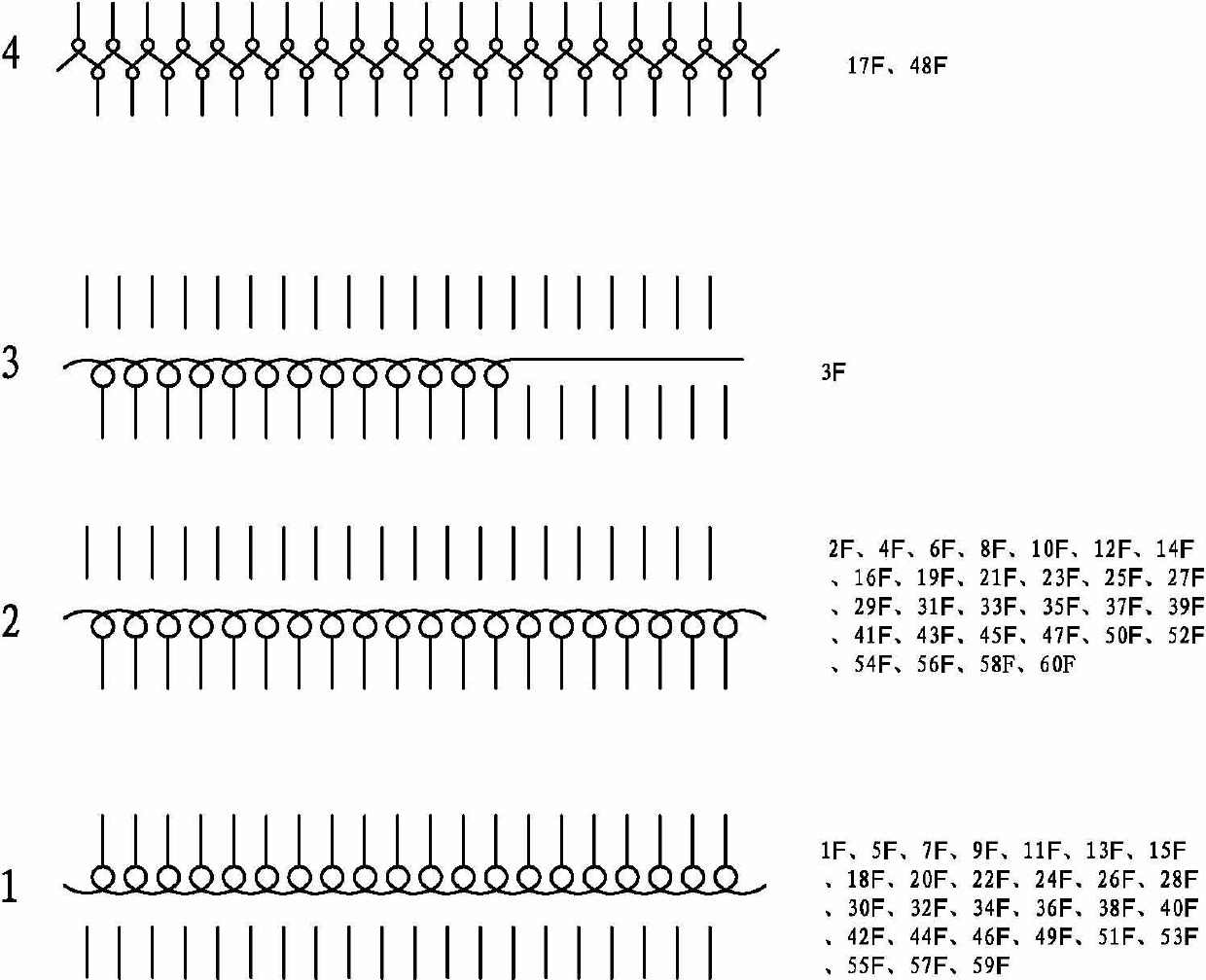

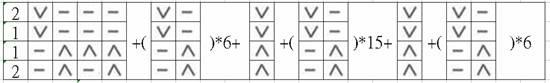

[0037] One of the specific implementations of the weaving process of a fabric with a mesh structure of the present invention includes the following steps:

[0038] Step 1, weaving: the vinylon water-soluble fiber is mixed and woven with the basic raw material fiber of the fabric, and the primary fabric is woven, and the vinylon water-soluble fiber is woven into the coil course in the minimum pattern cycle of the corresponding primary fabric;

[0039] Step 2. Finishing: Soak the primary fabric woven in step 1, dissolve the vinylon water-soluble fiber, and make the corresponding wale of the vinylon water-soluble fiber in the form of a loop structure lose connection, form a mesh structure, and obtain a mesh The finished fabric of the structure.

[0040] Wherein, in step 1, the vinylon water-soluble fiber is woven in the loop course in the minimum pattern cycle of the corresponding primary fabric in the form of a loop structure and a non-woven structure.

[0041] Another: also ca...

Embodiment 2

[0065] One of the specific implementations of the weaving process of a fabric with a mesh structure of the present invention includes the following steps:

[0066] Step 1, weaving: the vinylon water-soluble fiber is mixed and woven with the basic raw material fiber of the fabric, and the primary fabric is woven, and the vinylon water-soluble fiber is woven into the coil course in the minimum pattern cycle of the corresponding primary fabric;

[0067] Step 2. Finishing: Soak the primary fabric woven in step 1, dissolve the vinylon water-soluble fiber, and make the corresponding wale of the vinylon water-soluble fiber in the form of a loop structure lose connection, form a mesh structure, and obtain a mesh The finished fabric of the structure.

[0068] Specifically, in the first step, the vinylon water-soluble fiber is woven in the loop course of the corresponding minimum pattern cycle of the primary fabric in the form of a loop structure and a tuck structure.

[0069] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com