Blended foam material based on polycaprolactone (PCL) and modified polylactic acid (PLA) and preparation method thereof

A polycaprolactone and foaming material technology, applied in the field of foaming materials, can solve the problems of poor processing stability, poor impact strength, short service life, etc. The effect of improving the service life and improving the usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

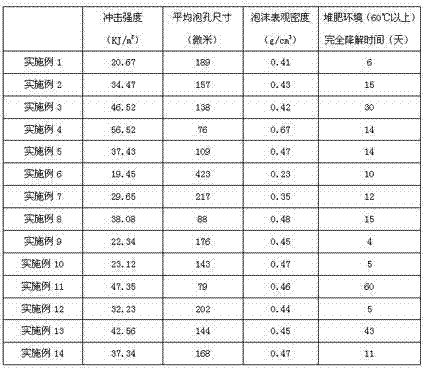

Examples

Embodiment 1

[0031] The raw material components are by weight: 80 parts of poly DL-lactic acid with a weight average molecular weight of 150,000, 5 parts of polycaprolactone with a weight average molecular weight of 30,000, 5 parts of hollow glass microspheres, 3 parts of nano calcium carbonate, 4 parts of even Nitrogendiformamide, 0.1 part of zinc oxide, 2 parts of hydrotalcite, 0.9 part of sodium dodecylbenzenesulfonate. The molecular weight distribution Mw / Mn value of polyDL-lactic acid is 1.6, the melting point is 164°C, and the crystallinity is 35%; the melting point of polycaprolactone is 60°C, and the crystallinity is 45%.

[0032]According to the above formula, the fully dried raw materials are mixed evenly in a high mixer, then extruded with a twin-screw extruder at 155°C, and granulated with a pelletizer to prepare a length of 5-10mm and a particle size of about 5mm. foaming masterbatch; put a certain amount of foaming masterbatch in the mold, heat foam molding on a flat vulcaniz...

Embodiment 2

[0034] The raw material components are by weight: 70 parts of poly DL-lactic acid with a weight average molecular weight of 150,000, 15 parts of polycaprolactone with a weight average molecular weight of 30,000, 5 parts of hollow glass microspheres, 3 parts of nano calcium carbonate, 4 parts of even Nitrogendiformamide, 0.1 part of zinc oxide, 2 parts of hydrotalcite, 0.9 part of sodium dodecylbenzenesulfonate.

[0035] According to the above formula, the fully dried raw materials are mixed evenly in a high mixer, then extruded with a twin-screw extruder at 155°C, and granulated with a pelletizer to prepare a length of 5-10mm and a particle size of about 5mm. foaming masterbatch; put a certain amount of foaming masterbatch in the mold, heat and foam on a flat vulcanizing machine at 180°C, the foaming time is 15min, and the apparent density is 0.43 g / cm 3 A polycaprolactone-modified polylactic acid-based blend foam material.

Embodiment 3

[0037] The raw material components are by weight: 60 parts of poly DL-lactic acid with a weight average molecular weight of 150,000, 25 parts of polycaprolactone with a weight average molecular weight of 30,000, 5 parts of hollow glass microspheres, 3 parts of nano calcium carbonate, 4 parts of even Nitrogendiformamide, 0.1 part of zinc oxide, 2 parts of hydrotalcite, 0.9 part of sodium dodecylbenzenesulfonate.

[0038] According to the above formula, the fully dried raw materials are mixed evenly in a high mixer, then extruded with a twin-screw extruder at 155°C, and granulated with a pelletizer to prepare a length of 5-10mm and a particle size of about 5mm. foaming masterbatch; put a certain amount of foaming masterbatch in the mold, heat foam molding on a flat vulcanizing machine at 180 °C, the foaming time is 15min, and the apparent density is 0.42 g / cm 3 A polycaprolactone-modified polylactic acid-based blend foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com