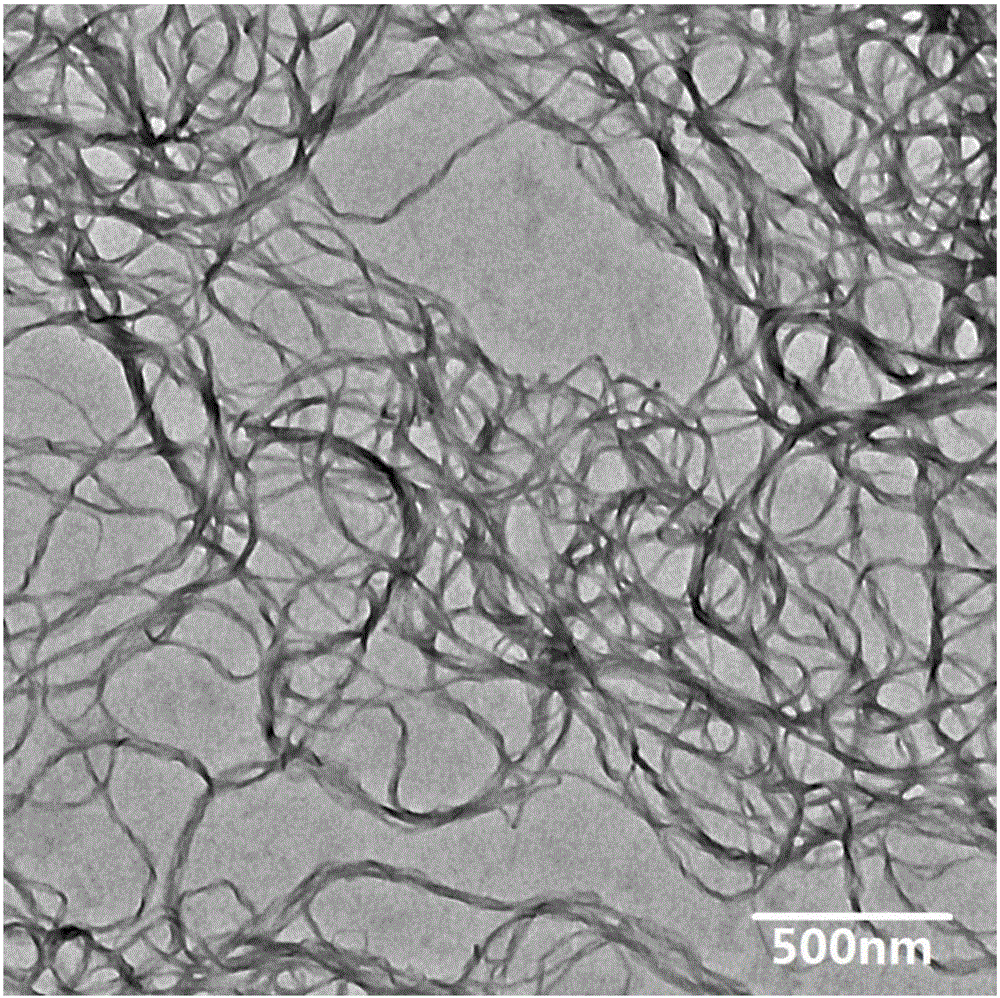

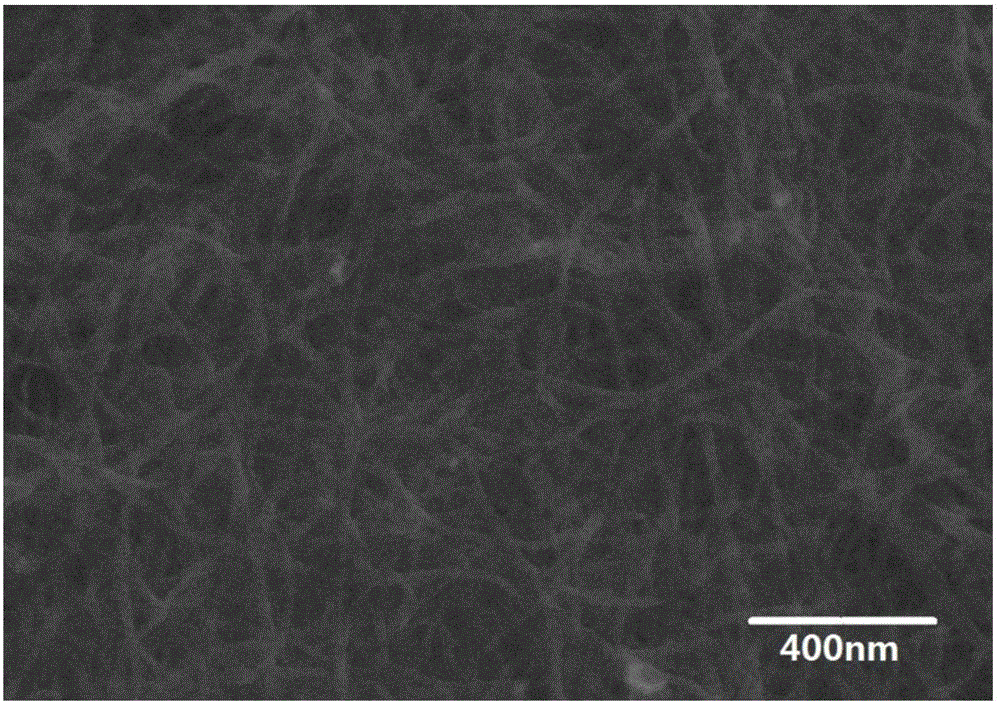

Preparation method of p-aramid nanofiber

A nanofiber, para-aramid fiber technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of destroying the properties of aramid fiber, long production cycle, complex production technology, etc., to reduce the post-processing process. , the effect of reducing production costs and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the para-aramid nanofiber proposed by the inventive method comprises the following steps:

[0016] (1) Modified polymerization:

[0017] Under the protection of nitrogen, add the solvent that has been dewatered into the reaction vessel, add the solubilizing salt and surfactant under stirring, and heat to 80-100°C to dissolve the solubilizing salt and surfactant to obtain the solubilizing salt and surfactant solution, the heating time is 45-60min, and z is cooled in a cold water bath for 10min to 0-15°C, and p-phenylenediamine (PPD) is added to the reaction vessel, after the p-phenylenediamine is dissolved, the reaction vessel is cooled To -15 ~ 0 ℃, then add terephthaloyl chloride (TPC), increase the stirring speed to 1000 ~ 2500r / min, continue the reaction, the reaction time is 5 ~ 10 minutes, the reaction temperature is -15 ~ 0 ℃, wait for the above Stop stirring after gelation occurs in the reaction system to obtain a jelly body, wherein th...

Embodiment 1

[0025] (1) Under the protection of nitrogen, add 100mL of N-methylpyrrolidone (NMP) that has undergone water removal treatment into the reaction vessel, and add the solubilizing salt CaCl under stirring. 24.844g, LiCl1.157g and surfactant PEG-2000 (polyethylene glycol of molecular weight 2000) 3g, and be heated to 100 ℃ and make solubilizing salt and tensio-active agent dissolve, obtain the solution of solubilising salt and tensio-active agent, The heating time was 45 minutes, and then cooled in a cold water bath for about 10 minutes to 15°C, and 4.326g of p-phenylenediamine (PPD) was added to the reaction vessel, and the reaction vessel was cooled to 0°C after the p-phenylenediamine was dissolved. Add terephthaloyl chloride (TPC) again, increase the stirring speed to 2000r / min, continue to react for 5 minutes, the reaction temperature is 0°C, stop stirring after gelation occurs in the above reaction system, and obtain a jelly body;

[0026] (2) Add 1L of dispersant N-methylpy...

Embodiment 2

[0030] (1) Under the protection of nitrogen, add 100mL of solvent N,N-dimethylformamide (DMF) and N,N-dimethylacetamide (DMAc) (volume ratio 1:1) after water removal treatment In the reaction vessel, add the solubilizing salt CaCl under stirring 2 6g and 3g of surfactant mPEG (polyethylene glycol monomethyl ether with a molecular weight of 2000), and heated to 80°C to dissolve the solubilizing salt and the surfactant to obtain a solution of the solubilising salt and the surfactant, and the heating time is 60min , and then cool in a cold water bath for about 10 minutes to 10°C, add 4.326g of p-phenylenediamine (PPD) into the reaction vessel, and cool the reaction vessel to -5°C after the p-phenylenediamine is dissolved. Add terephthaloyl chloride (TPC) again, increase the stirring speed to 2500r / min, continue to react for 8 minutes, the reaction temperature is -5°C, stop stirring after gelation occurs in the above reaction system, and obtain a jelly body;

[0031] (2) Add 2L o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com