Gemini type air humidity reversal agent compound as well as preparation method and application thereof

The technology of a gas-wet reversal agent and compound is applied in the field of the twin-type gas-wet reversal agent compound and its preparation, which can solve the problems of the research on the wetting reversal of the core surface, the lack of on-site conditions, and the high requirements for production conditions, etc. Achieving good hydrophobic and oleophobic properties, favorable for field promotion and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1) The preparation of the Gemini type VIR compound (formula I, n=1), the steps are as follows:

[0079] (1) Take 415g (1mol) of perfluorooctanoic acid in a glass reactor, add 8g (0.1mol) of pyridine under stirring conditions, and slowly drop 167g (1.4mol) of thionyl chloride into Wherein, and continue stirring for 1 hour, then heat up to 80°C, reflux the thionyl chloride for 4 hours, cool to room temperature, and collect 128°C-130°C fractions by atmospheric distillation, which is product A (compound of formula II). The rate is 97%.

[0080] (2) Take 300mL of absolute ethanol in a glass reactor, add 215g (0.5mol) of the product A obtained in step (1) and 14g (0.25mol) of calcium oxide into it, and under stirring, pass through fully dried ammonia Gas 44L (2mol), and continue to stir for 4 hours, control temperature below 15 ℃, carry out suction filtration after reaction finishes, utilize rotary evaporator to remove solvent again, dry to obtain finished product B (compou...

Embodiment 2

[0088] Embodiment 2, preparation of gemini type gas humidity reversal agent compound

[0089] As described in Example 1, the difference is that the molar ratio of product C to chloroacetic acid in step (4) is 1:1.2. The final product obtained through step (5) is sodium N,N-bis(perfluorooctanoyl)imide acetate, and the yield of the obtained product is 92%.

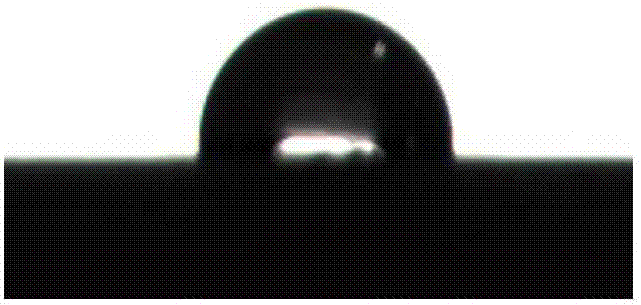

[0090] And configure the solution with a mass fraction of 0.05%, soak shale with it for 48 hours, place it at room temperature for 8 hours after drying, measure the contact angle of the water phase and oil phase on the shale surface after treatment, and the water phase contact angle is 119 ° (such as image 3 shown), the oil phase contact angle is 92° (as Figure 10 shown).

Embodiment 3

[0091] Embodiment 3, preparation of gemini type gas humidity reversal agent compound

[0092] As described in Example 1, the difference is that the chlorocarboxylic acid in the reactant of step (4) is chloropropionic acid. The final product obtained is sodium N,N-bis(perfluorooctanoyl)iminopropionate, and the yield of the obtained product is 88%.

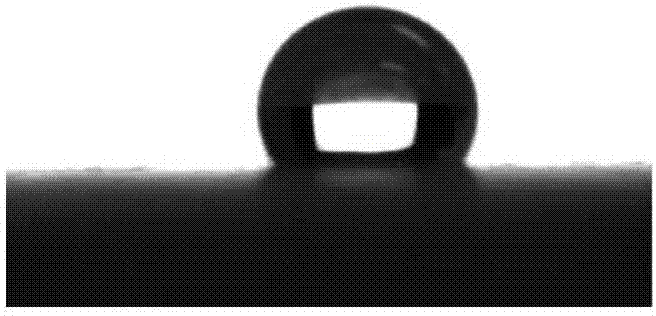

[0093] The product was added with deionized water to prepare a solution with a mass fraction of 0.05%, soaked in shale for 48 hours, dried and placed at room temperature for 8 hours, and measured the contact angle of the water phase and oil phase on the shale surface after treatment. The phase contact angle is 117° (such as Figure 4 shown), the oil phase contact angle is 127° (as Figure 11 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com