Active water-nitrogen injection combination fracturing fast flow-back production increase method for coal-bed gas well

A technology for coalbed methane wells and composite fracturing, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc. layer permeability, reducing methane partial pressure, and reducing coal reservoir pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

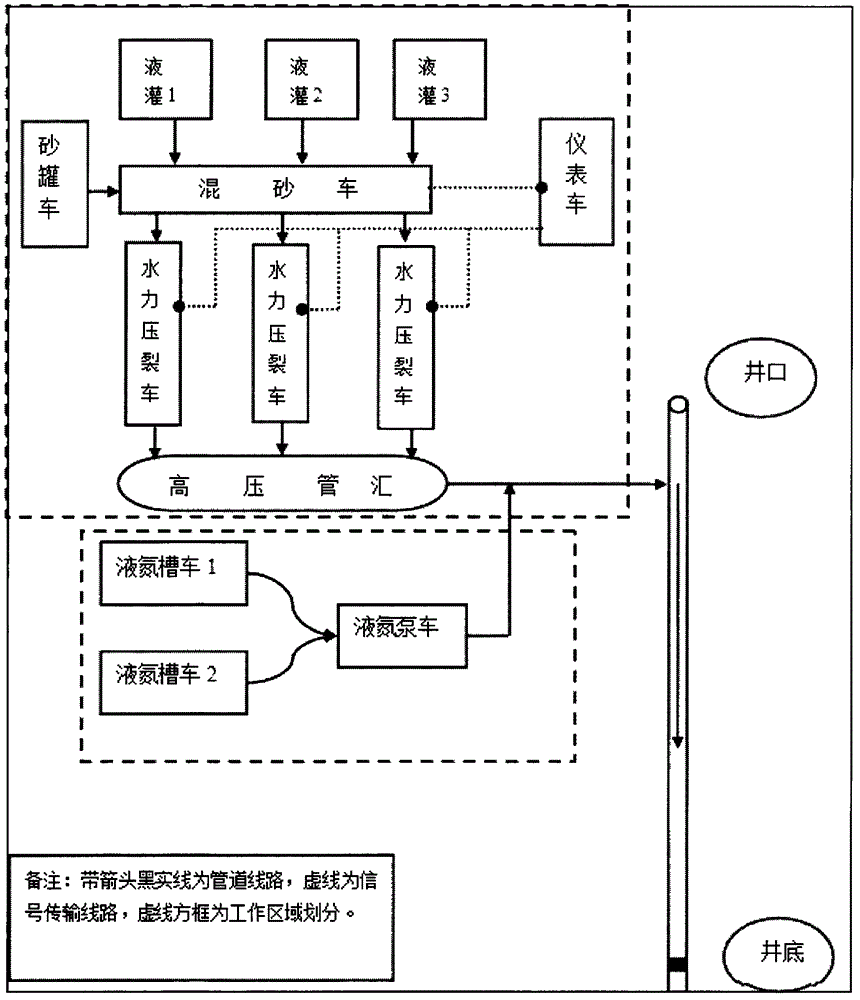

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with embodiments.

[0009] A rapid flowback and production increase method for combined fracturing with active water-nitrogen injection in a coalbed methane well, characterized in that it comprises the following steps:

[0010] (a) According to the design scale of fracturing, first configure the liquid volume of active water, and configure it in strict accordance with the ratio and quality requirements of active water;

[0011] (b) Wellheads of coalbed methane wells, command vehicles, hydraulic fracturing vehicles, sand mixing vehicles and liquid nitrogen pump vehicles are well connected;

[0012] (c) Conduct pressure test according to fracturing design requirements to ensure that there is no puncture or leakage of high-pressure manifold;

[0013] (d) The liquid nitrogen pump truck shall pump nitrogen according to the fracturing design requirements, and the nitrogen discharge temperature shall not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com