Method for preparing residue free fracturing fluid

A preparation method and a residue-free technology, applied in the field of fracturing fluid, can solve the problems of permeability and formation permeability damage, affecting fracturing stimulation effect, residual microgel, etc., achieving low surface tension, good anti-swelling effect, The effect of continuous preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Add 6 grams of NaOH and 13.5 grams of KCl into 300 mL of water, stir to make them fully dissolve, and form a residue-free fracturing fluid base fluid;

[0024] 2. Add 15 grams of unsaturated fatty acid with 18 carbon atoms to 300 mL of base liquid under high-speed stirring, stir until the vortex is closed, and form a residue-free product with a viscosity of 60-150 mPa.s (milliPascal seconds) within 60 seconds. Fracturing fluid.

Embodiment 2

[0026] 1. Add 12 grams of KCl to 300 mL of water to fully dissolve it to form a residue-free fracturing fluid base fluid;

[0027] 2. Add 5 grams of unsaturated fatty acid salt with 18 carbon atoms to 300 mL of base liquid under high-speed stirring, stir until the vortex is closed, and form a liquid with a viscosity of 50-160 mPa.s (milliPascal seconds) within 60 seconds. Residue-free fracturing fluid.

[0028] For the effect test of embodiment 1:

[0029] The performance test of non-residue fracturing fluid is carried out with reference to the standard SY / T 5107-1995 "Performance Evaluation of Water-based Fracturing Fluid".

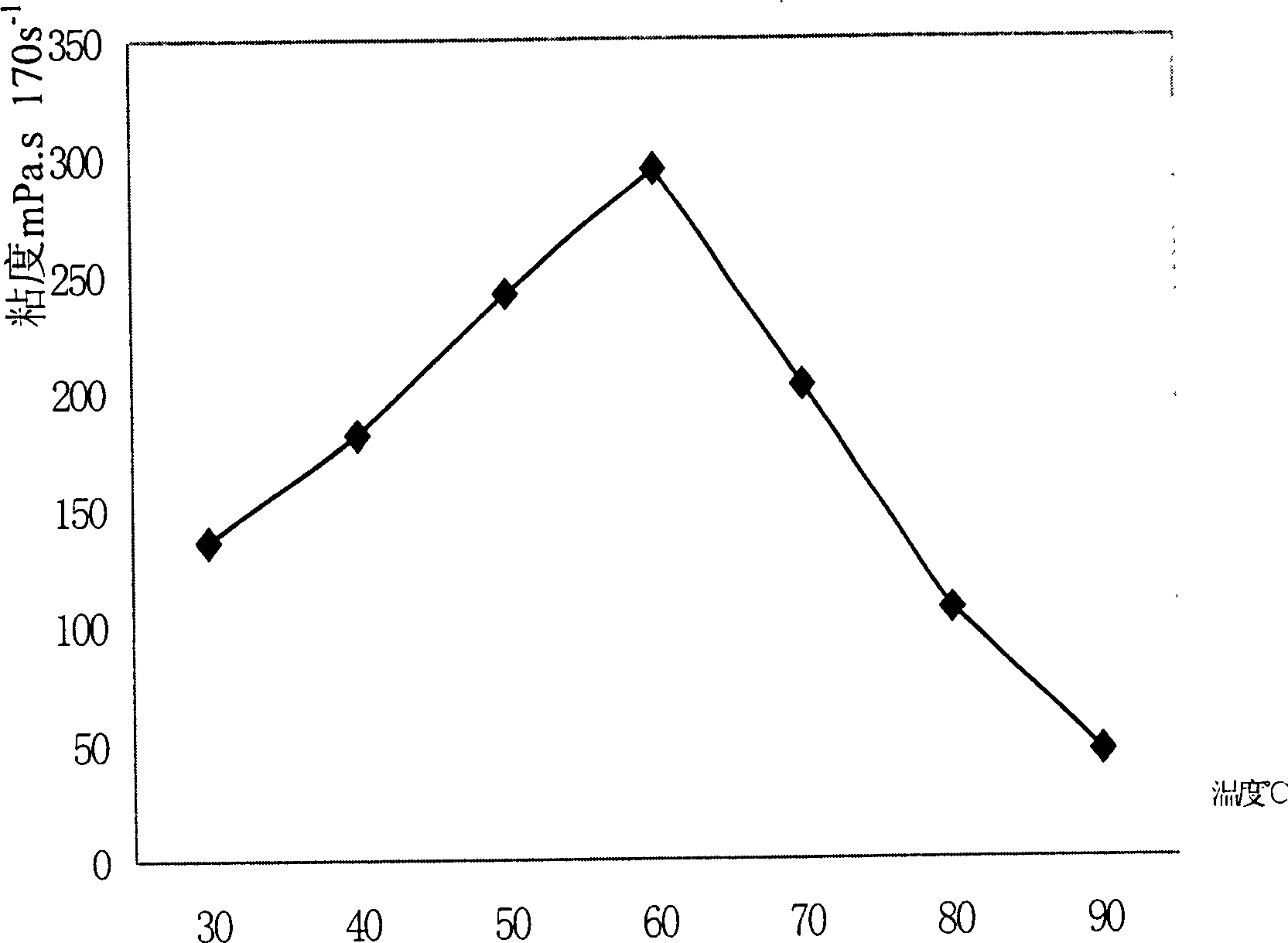

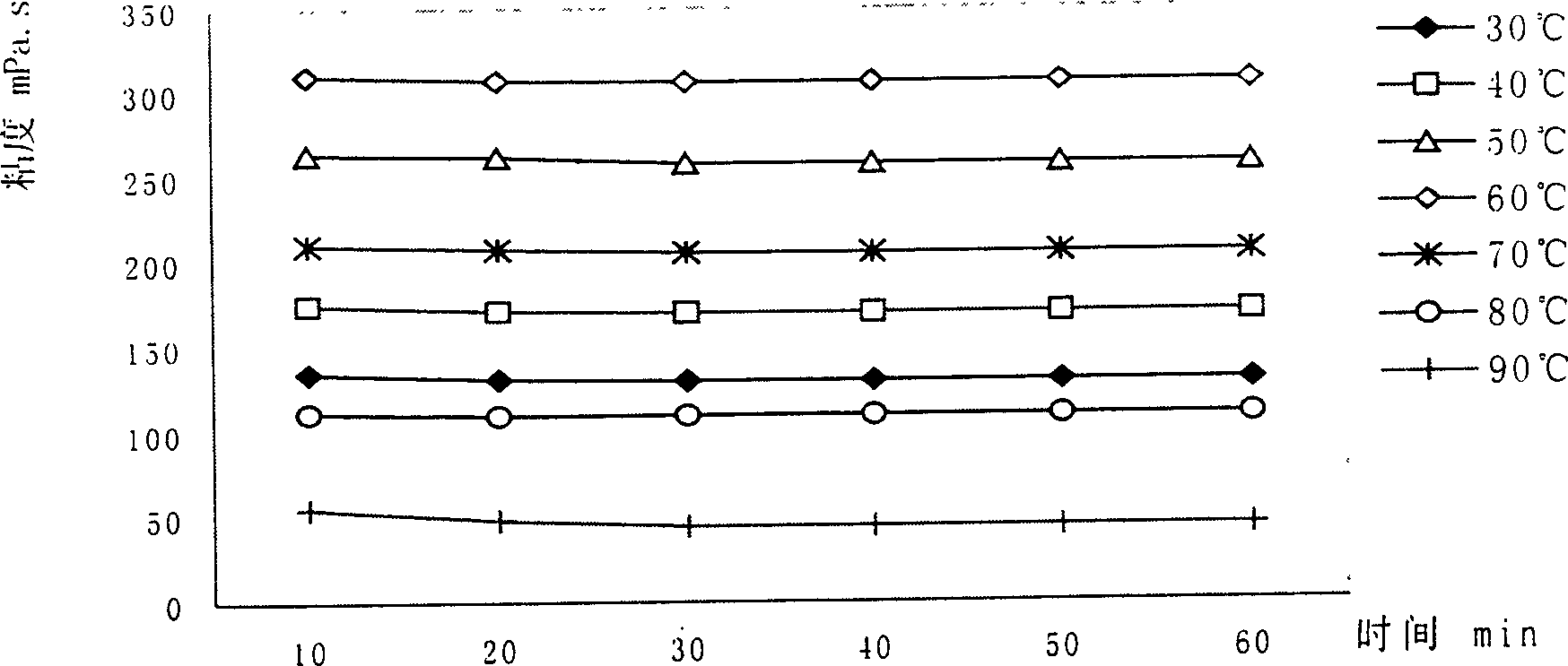

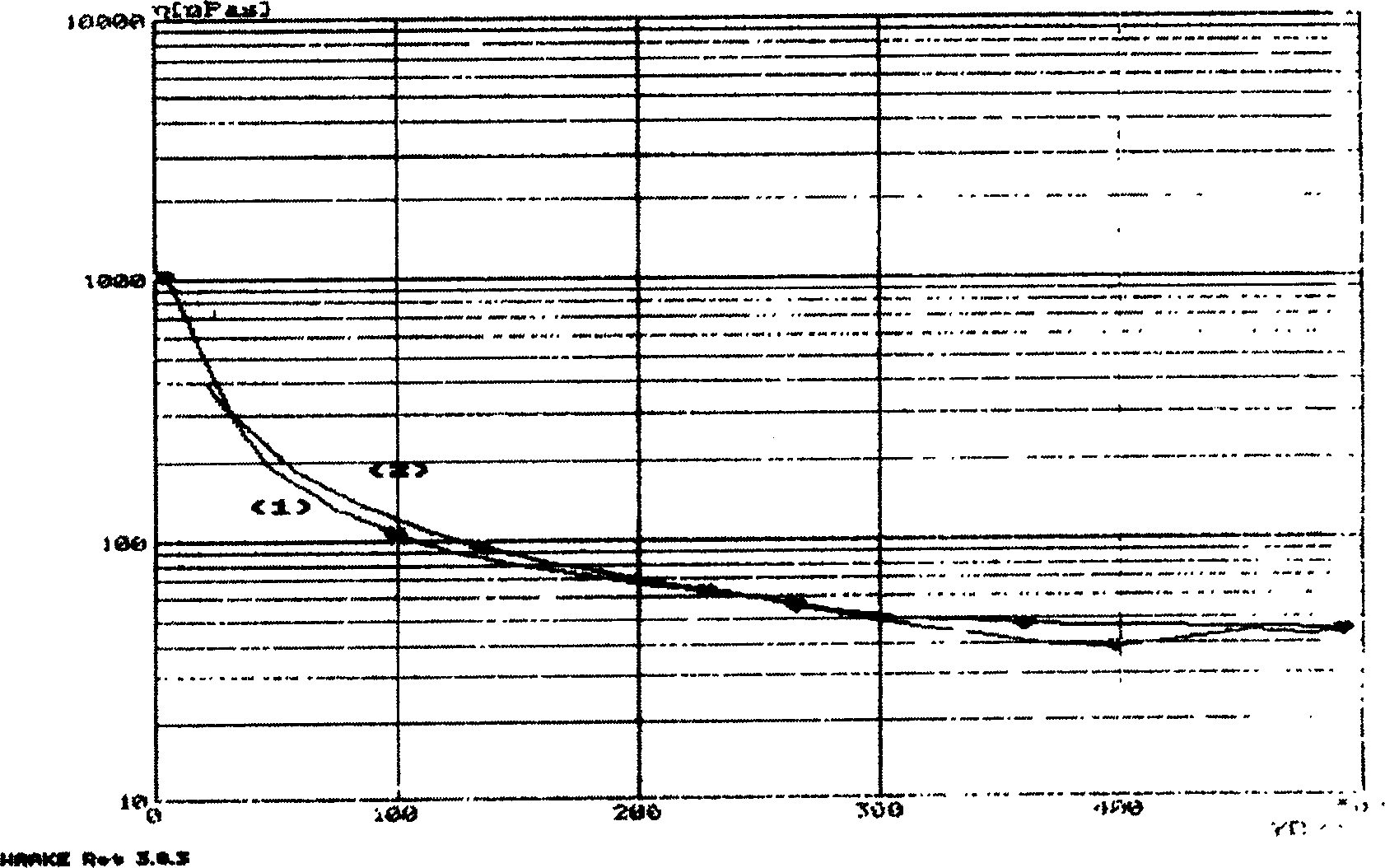

[0030] (1) Viscosity-temperature performance (the experimental instrument is a German HAAK RV30 rotational viscometer)

[0031] figure 1 Viscosity-temperature performance curve of no-residue fracturing fluid

[0032] temperature, ℃

30

40

50

60

70

80

90

Fracturing fluid viscosity, mPa.s

1...

Embodiment 3~6

[0078] Embodiment 3~6 and effect test thereof

[0079] Example

[0080] temperature, ℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com