Large diameter multi-layer fracturing string suitable for 120℃, 70mpa environment

A fracturing string and large-diameter technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large friction resistance and obvious throttling effect, so as to improve time efficiency and reduce throttling loss , the effect of meeting the needs of fracturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

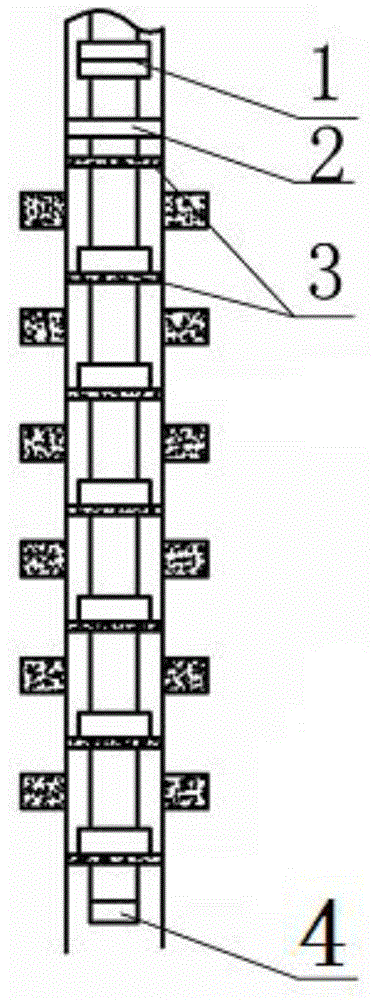

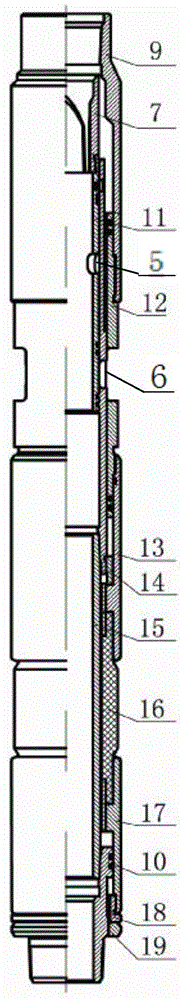

[0014] Depend on figure 1 and figure 2 As shown, a large-diameter multi-layer fracturing string suitable for 120°C and 70MPa environments includes a safety joint 1 and a plug 6. The bottom of the safety joint 1 is connected to a hydraulic anchor 2, and the bottom of the hydraulic anchor 2 is connected to a There are several packers 3, the upper part of the packer 3 is connected with a sand blaster, and the bottom of the pipe string is connected with a plug 6.

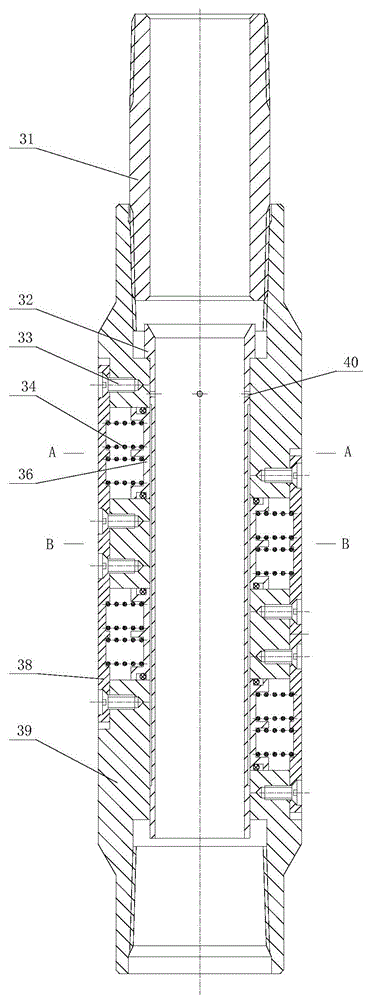

[0015] The hydraulic anchor 2 includes a short joint 31, the lower end of the short joint 31 is threadedly connected to a housing 39, and the housing 39 is provided with a plurality of fluke holes 37, and there are 12 fluke holes 37 along the shaft. There are 4 rows, 3 in each row, and the fluke holes 37 in each row are evenly distributed along the circumferential direction, and the fluke holes 7 between two adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com