Chemical-heat-generation efficient gel breaking method used in oil-gas well fracturing process

A technology for chemical heat production and oil and gas wells, applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of uneven gel breaking dose, strict temperature requirements, limited application range, etc., and achieve the goal of promoting The effect of oxidative chain scission of macromolecules, reduction of labor intensity, and reduction of permeability damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The low-temperature gel breaking test was carried out indoors. The test temperature was 50°C. Add 0.04% ammonium persulfate to 100mL guar gum cross-linked jelly, and place it at a constant temperature of 50°C for 12 hours. The viscosity of the gel breaking solution was 24mPa·s. Add 0.04% ammonium persulfate to the same 100mL jelly, add 5g of maleic acid glycoside, and place it at a constant temperature of 50°C for 30min, and the viscosity of the gel breaking solution is 3mPa·s. Scanning electron microscopy was performed for visual analysis, the results are as follows figure 1 (without addition of thermogenic chemicals) and figure 2 (Adding maleic acid), the results show that the chemical thermogenic gel breaking is obviously more thorough, the molecules are smaller, and the damage is less.

Embodiment 2

[0042] The low-temperature gel breaking test was carried out indoors. The test temperature was 50°C. Add 0.04% ammonium persulfate to 100mL of hydrophobic association jelly, and place it at a constant temperature of 50°C for 720min. The viscosity of the gel breaking solution was 42mPa·s. Add 0.04% ammonium persulfate to the same 100mL jelly, add 5g of polyimide, and place it at a constant temperature of 50°C for 48min, and the viscosity of the gel breaking solution is 4.8mPa·s.

[0043] In order to verify the gel-breaking effect of the present invention, the application of a certain block implementation technology verification is introduced as follows:

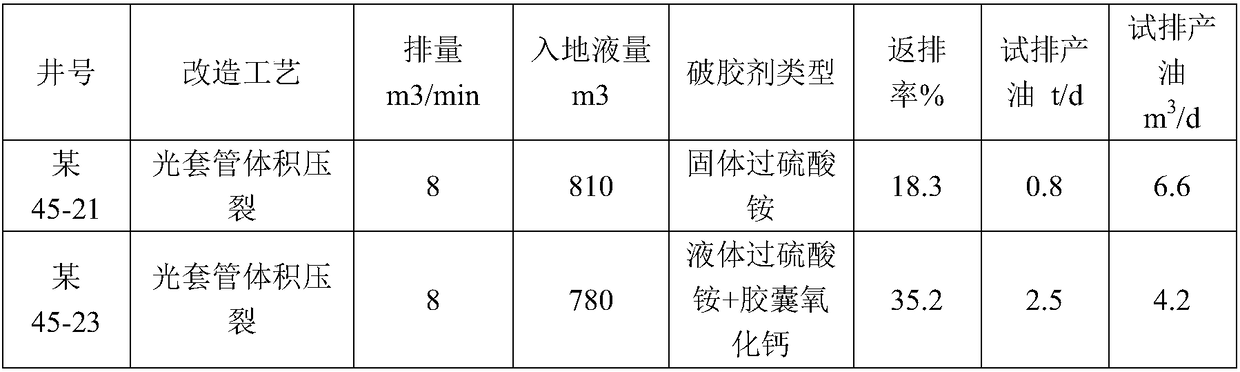

[0044] The block is 7 layers long, and the reservoir temperature measured by the downhole pressure thermometer in the early stage is 48.6°C. Two wells (a 45-21 and a 45-23) located in the same well site in this block are undergoing volume fracturing. From August 3, 2016 to August 10, 2016, the well site carried out light casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com