Method for temporarily plugging diversion fracturing by using salinity response type emulsion

A technology of emulsion and salinity, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of difficult injection of diverting agents, weak plugging strength, and inability to migrate, and achieve low cost , good plugging performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

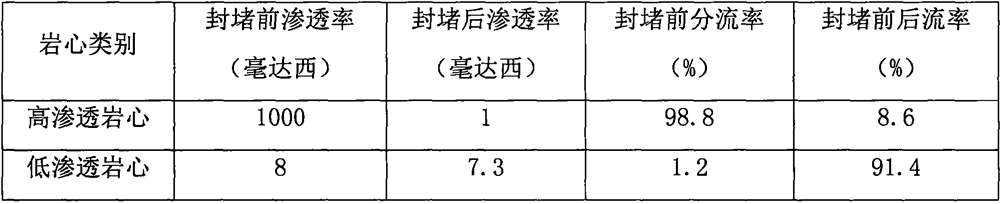

Embodiment 1

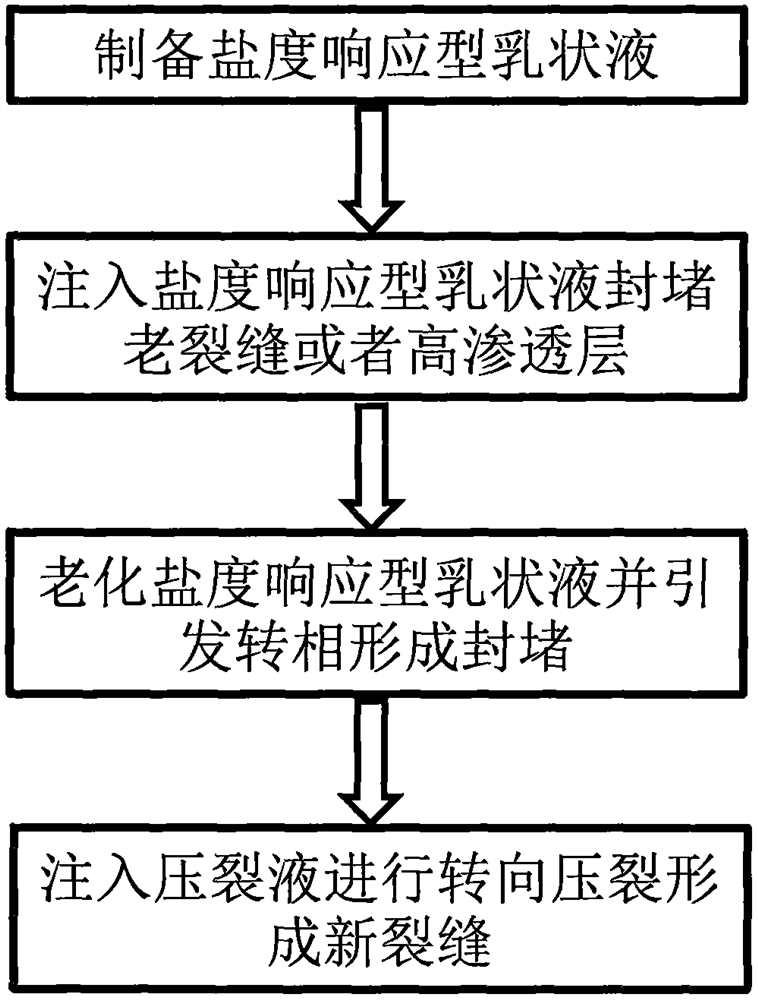

[0027] Such as figure 1A salinity-responsive emulsion is shown as a method for temporarily plugging and diverting fracturing, including the following steps:

[0028] Step 1. Prepare a salinity-responsive emulsion, which is characterized in that it includes a thick oil, a hydrophilic emulsifier, an lipophilic emulsifier, and dosing water; the salinity-responsive emulsion The viscosity at 60°C in the liquid is 2800mPa·s The mass fraction of heavy oil is 24%, the mass fractions of magnesium lithium silicate nanoparticles and sodium petroleum sulfonate are 0.4% and 0.4% respectively, magnesium stearate nanoparticles and The mass fraction of the disc 60 type emulsifier is 0.5% and 0.3% respectively, and the mass fraction of clear water is 74.4%; the preparation of salinity-responsive emulsion comprises the following steps:

[0029] Step 101, prepare a hydrophilic emulsifier aqueous solution, take 74.4g of clear water and add it to a beaker at room temperature, add 0.4g of magnesiu...

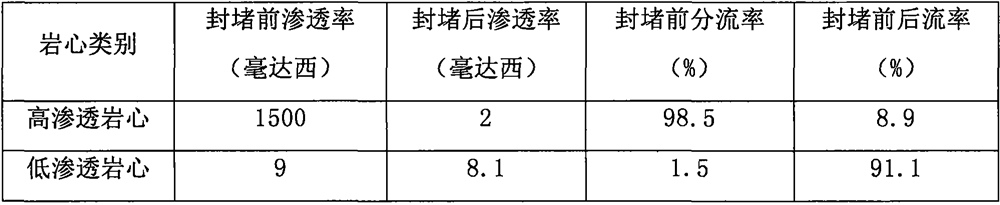

Embodiment 2

[0043] The difference between this example and Example 1 is that the salinity-responsive emulsion prepared in step 1 in this example is different. The salinity-responsive emulsion in this example includes heavy oil, hydrophilic emulsifier, lipophilic type emulsifier and dosing water; the viscosity at 60°C in the salinity-responsive emulsion is that the mass fraction of 1500mPa·s heavy oil is 28%, and the mass fractions of Tween 80 emulsifier and sodium petroleum sulfonate are respectively 0.3% and 0.25%, the massfraction of magnesium stearate nanoparticles is 0.65%, and the massfraction of clear water is 70.8%; the preparation of salinity-responsive emulsion comprises the following steps:

[0044] Step 101, prepare a hydrophilic emulsifier aqueous solution, take 70.8g of clear water and add it to a beaker at room temperature, add 0.3g of Tween 80 type emulsifier and 0.25g of petroleum sodium sulfonate to the clear water, and use a homogenizer or an emulsifier in the Stir for 1...

Embodiment 3

[0058] The difference between this example and Example 2 is that the salinity-responsive emulsion prepared in step 1 in this example is different. The salinity-responsive emulsion in this example includes heavy oil, hydrophilic emulsifier, lipophilic type emulsifier and dosing water; the viscosity at 60°C in the salinity-responsive emulsion is that the mass fraction of 3500mPa·s heavy oil is 26%, and the mass fraction of lithium magnesium silicate nanoparticles and Tween 80 type emulsifier The fractions are 0.3% and 0.3% respectively, the mass fractions of Span 60 emulsifier and OP-4 emulsifier are respectively 0.3% and 0.4%, and the mass fraction of clear water is 73.7%; the preparation of salinity-responsive emulsion comprises the following steps :

[0059] Step 101, prepare a hydrophilic emulsifier aqueous solution, take 73.7g of clear water and add it to a beaker at room temperature, add 0.3g of lithium magnesium silicate nanoparticles and 0.3g of Tween 80 emulsifier to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com