Fluorocarbon surfactant as well as preparation method and application thereof

A technology of fluorocarbon surfactants and active agents, which is applied in the direction of sulfonate preparation, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problems of high price and poor water solubility of fluorocarbon surfactants, and achieve easy industrial application, Good temperature resistance and the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

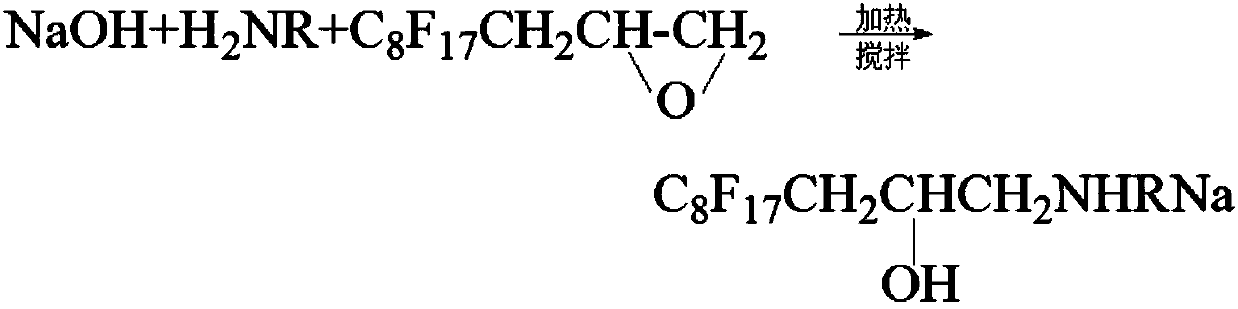

[0017] The preparation method of a kind of fluorocarbon surfactant provided by the embodiment of the present invention, it comprises the following steps: After mixing caustic alkali, amino compound, 3-perfluorooctyl propylene oxide with the first solvent, after 60-90 Under the temperature condition of ℃, react for 10-30h, and the amino compound is taurine or amino acid.

[0018] It should be noted that, after mixing caustic alkali, taurine or amino acid, and 3-perfluorooctyl propylene oxide with the first solvent, epoxy group ring-opening polymerization occurs at a temperature of 65-75°C to obtain fluorocarbon Surfactant. Caustic alkali can be common caustic alkalis such as sodium hydroxide, potassium hydroxide, take sodium hydroxide as example, the preparation method of this fluorocarbon surfactant can be represented by following equation:

[0019]

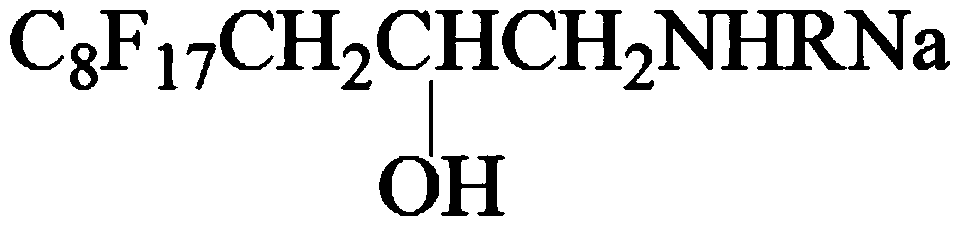

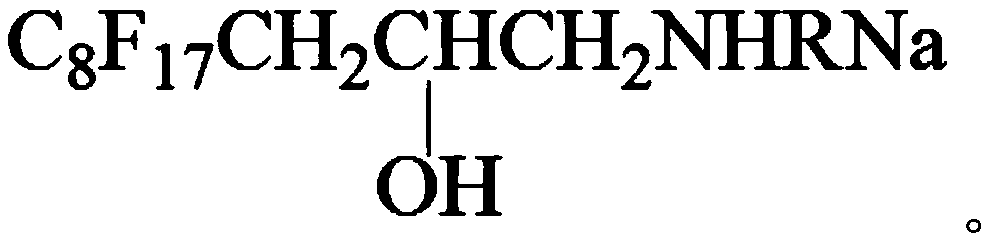

[0020] In the formula, R is a polar group containing 2-16 carbon atoms.

[0021] Specifically, taurine in the present inve...

Embodiment 1

[0033] The present embodiment provides a kind of preparation method of fluorocarbon surfactant, it comprises the following steps:

[0034] In a three-necked flask equipped with a condenser tube and a magnetic stirrer, add 128.2g of water, 64.1g of methanol, 64.1g of isopropanol, 4g (0.1mol) of sodium hydroxide, stir well and add 12.5g (0.1mol) of taurine acid, the temperature was raised to 70°C, and 47.6g (0.1mol) of 3-perfluorooctyl propylene oxide was slowly added dropwise, and reacted for 16 hours to obtain a solution containing a fluorocarbon surfactant with an effective content of 20%.

[0035] This embodiment also provides a fluorocarbon surfactant, which is prepared by the above-mentioned method.

Embodiment 2

[0037] The present embodiment provides a kind of preparation method of fluorocarbon surfactant, it comprises the following steps:

[0038] In a three-necked flask equipped with a condenser and a magnetic stirrer, add 128.2g of water, 64.1g of methanol, 64.1g of isopropanol, 4.4g (0.11mol) of sodium hydroxide, stir well and then add 13.77g (0.11mol) of beef Sulfonic acid, heat up to 70°C, slowly add 47.6g (0.1mol) of 3-perfluorooctyl propylene oxide dropwise, and react for 24 hours to obtain a fluorocarbon surfactant solution with an effective content of 20%.

[0039] This embodiment also provides a fluorocarbon surfactant, which is prepared by the above-mentioned method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com