Method for detecting source of oxide scale peeled off from inner wall of heated surface of boiler

An inspection method and oxide skin technology, which is applied in the direction of material analysis by measuring secondary emissions, can solve the problems of waste and time-consuming of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] The first step is to randomly select scales that are bright gray on one side and black or dark gray on the other side from the scale peeled off on the inner wall of the tube panel on the heating surface of the boiler; when selecting scales, all scales that are obviously different in shape or color should be Inclusive, the number of picks should be no less than 3 pieces each.

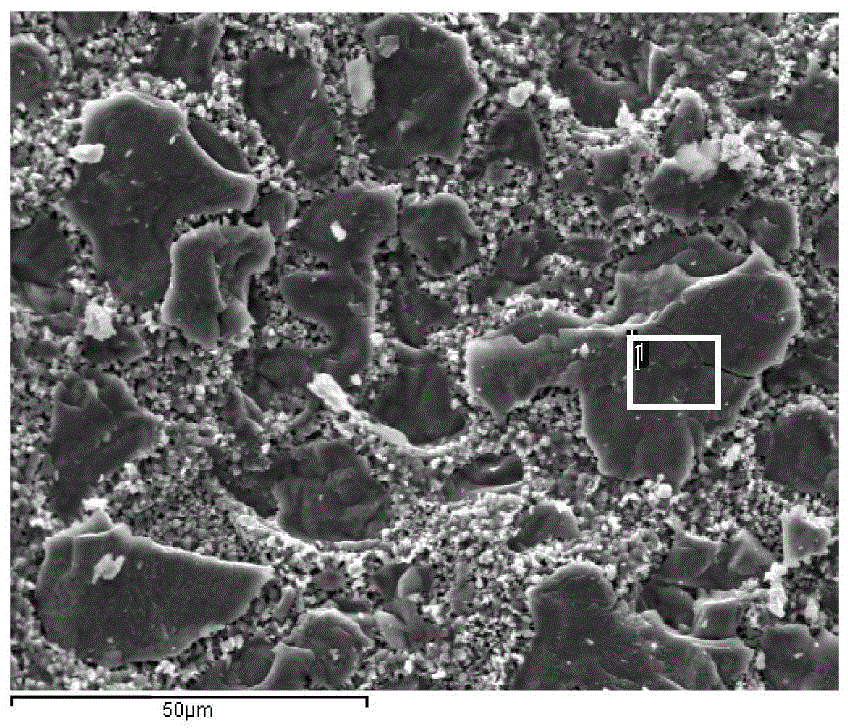

[0026] In the second step, observe the black or dark gray side of the oxide scale with a scanning electron microscope equipped with an X-ray energy spectrometer to find the flaky inner layer residues of the oxide scale, and perform X-ray energy spectroscopy on the oxide scale inner layer residues. Spectrum analysis; flaky oxide skin inner layer residue, the composition of the oxide skin inner layer residue has trace elements in addition to Fe and O;

[0027] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com