Mechanical conveying mechanism

A technology of mechanical feeding and racking, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of difficult maintenance, complex structure, easy damage of structure, etc., and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

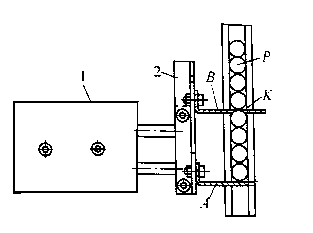

[0013] combined with figure 1 The mechanical feeding mechanism shown includes a frame and a chute P, and a double-axis cylinder 1 is connected by bolts on the frame. The double-axis cylinder 1 includes a cylinder cylinder, two piston rods, and a front plate 2 connected by bolts to the two piston rods. The front plate 2 is perpendicular to the ground, and the front plate 2 extends vertically to open a long hole. The length of the long hole is equal to the length of a workpiece. One side of the long hole is provided with a square mounting hole every other workpiece length. The front plate 2 Bolt the bottom of the long hole to connect the horizontal low-position baffle A, and the front plate 2 is bolted to a horizontal high-position baffle B in one of the installation holes in the long hole, and install it in the specific installation hole according to the needs How many workpieces are conveyed at a time depends. When deciding to change the conveying quantity, loosen the bolts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com