Method for analyzing ability of diamond-like carbon film to seal hydraulic servo actuator of aircraft

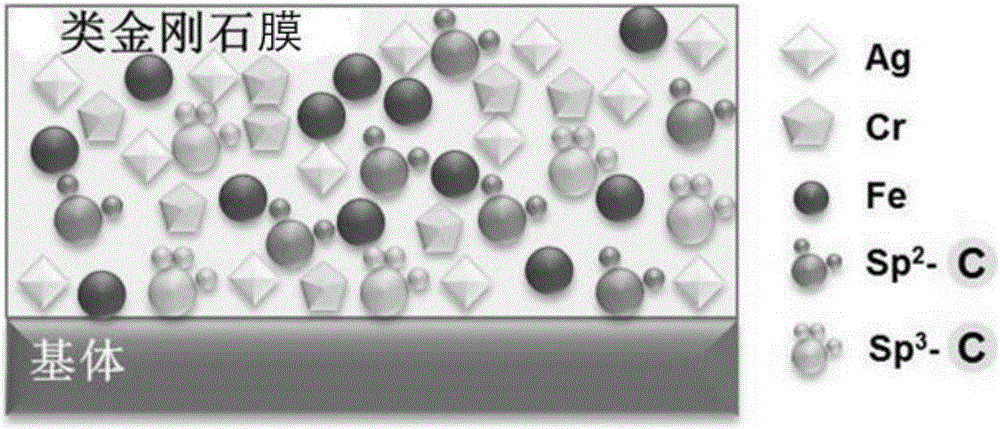

A diamond-like film and hydraulic servo technology, applied in the direction of material analysis, material excitation analysis, material analysis using radiation diffraction, etc., can solve the problems of abrasive wear at the extension end of the piston rod, reduce the friction coefficient data, and improve the surface hardness , the effect of improving the toughness of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

[0041] 1. Preparation of diamond-like film:

[0042] The base material is 440A stainless steel as the material of the actuator piston rod, and 30 sheets of 10×10 cm are made of 440A stainless steel base material. The base material is ultrasonically cleaned in acetone solution for 20 minutes, dried with nitrogen, and placed in a vacuum. room to be deposited.

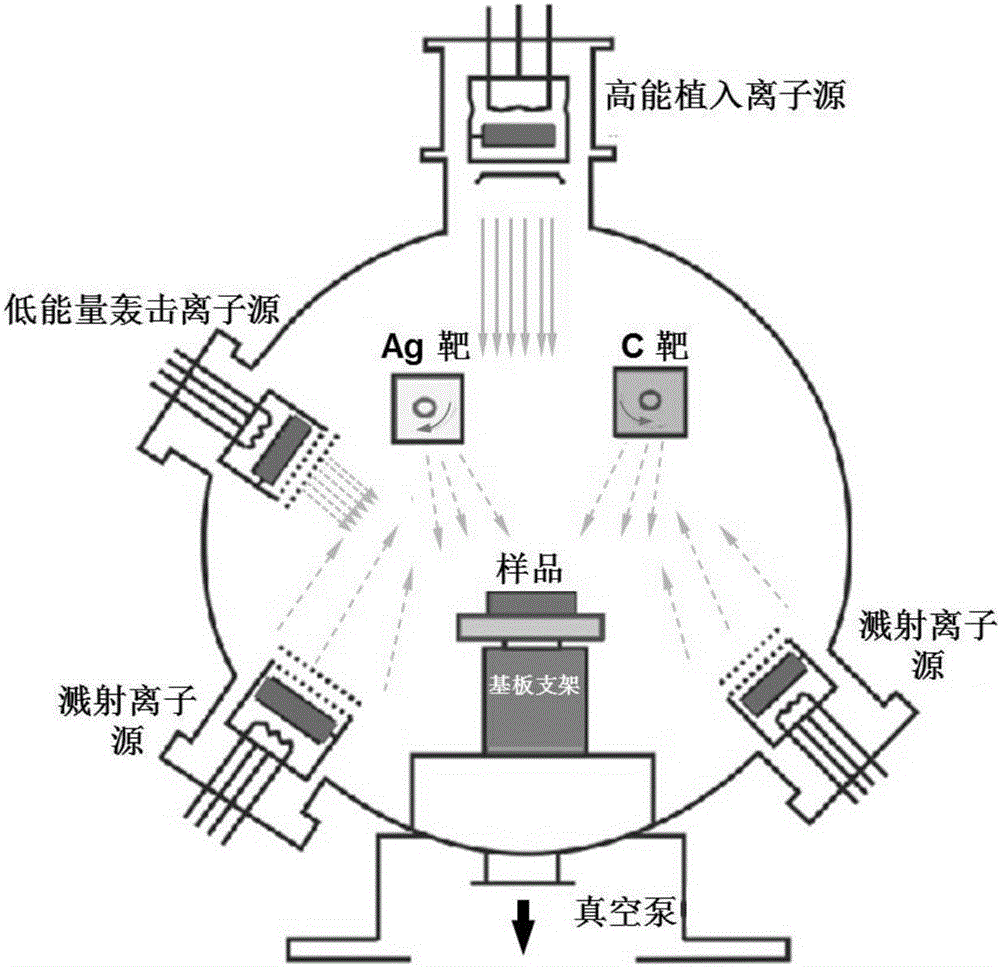

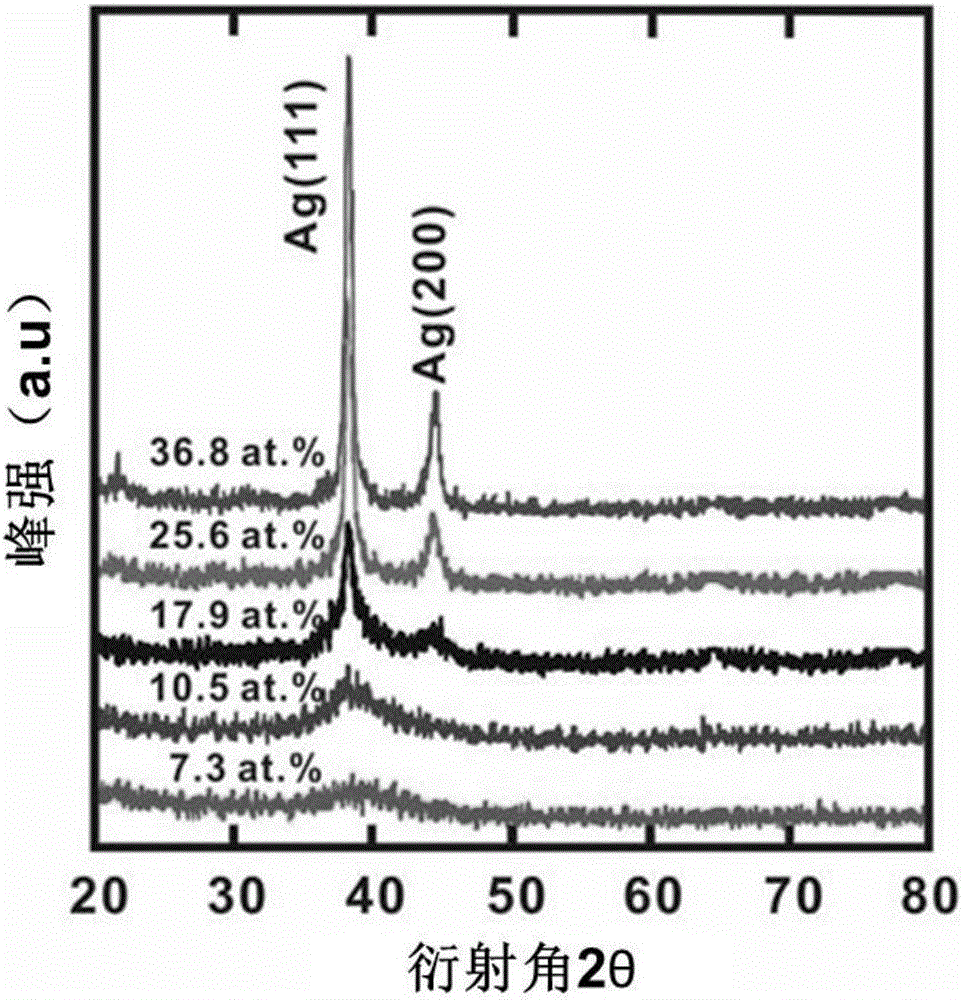

[0043] Pump the background vacuum to 1.8×10 -4 After Pa, use 5keV / 20mA high-energy ion source Ar + Bombard the surface of the sheet for 10 minutes; start the sputtering silver target ion source, the voltage and ion beam current are 1200eV / 35mA, and deposit an Ag spacer layer with a thickness of about 0.2 μm on the substrate. Then start the sputtering carbon target ion source to deposit a layer of Ag-DLC film with a thickness of 1 μm on the substrate; the ion source voltage and ion beam current of the sputtering carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com