Inorganic coating method for titanium dioxide

An inorganic coating, titanium dioxide technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve problems such as time-consuming experiments, little research on the influence of dispersibility and surface potential, and production cycle influence, etc. To achieve the effect of less number of experiments, reduced workload of experiments, and strong representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

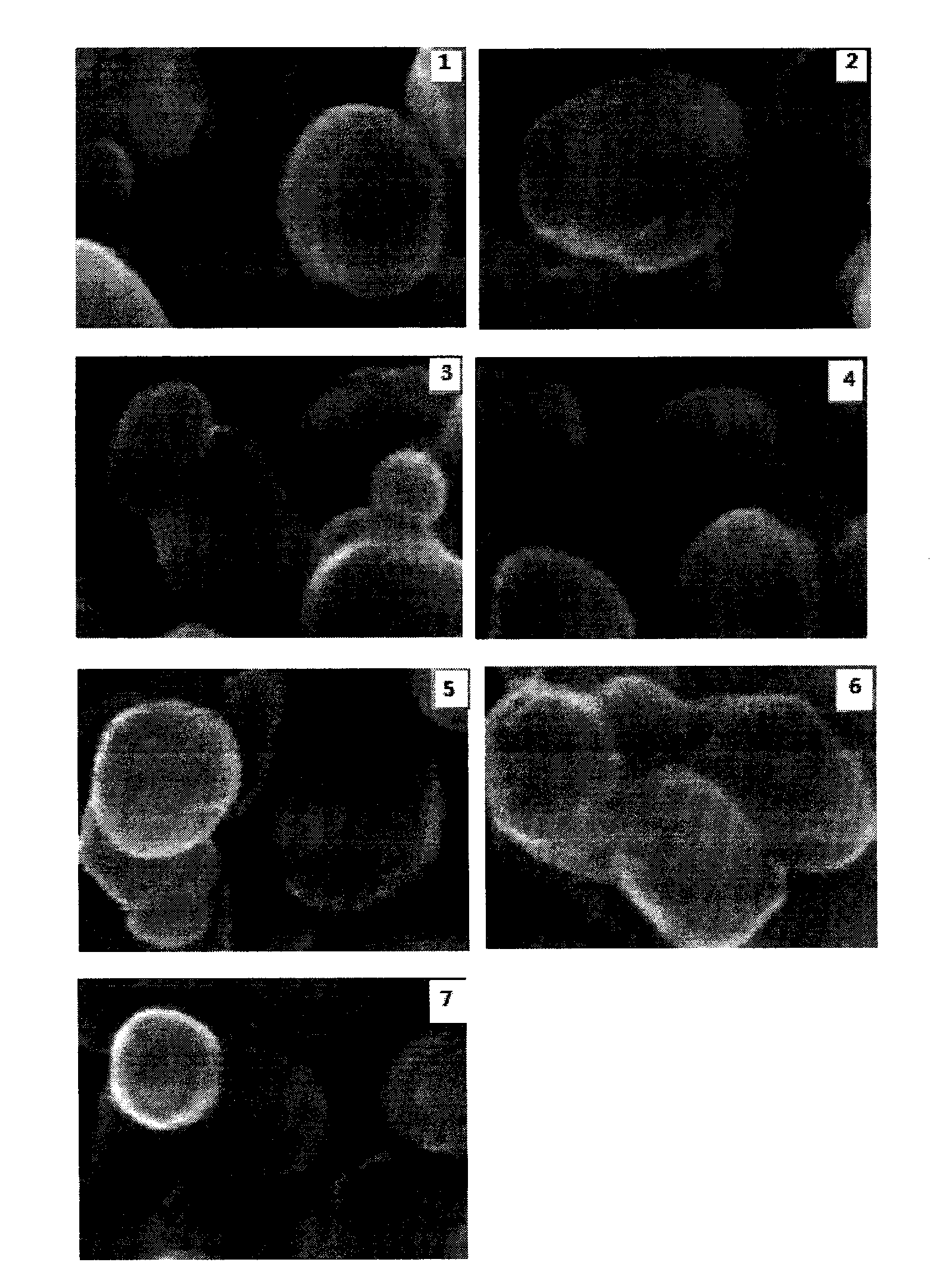

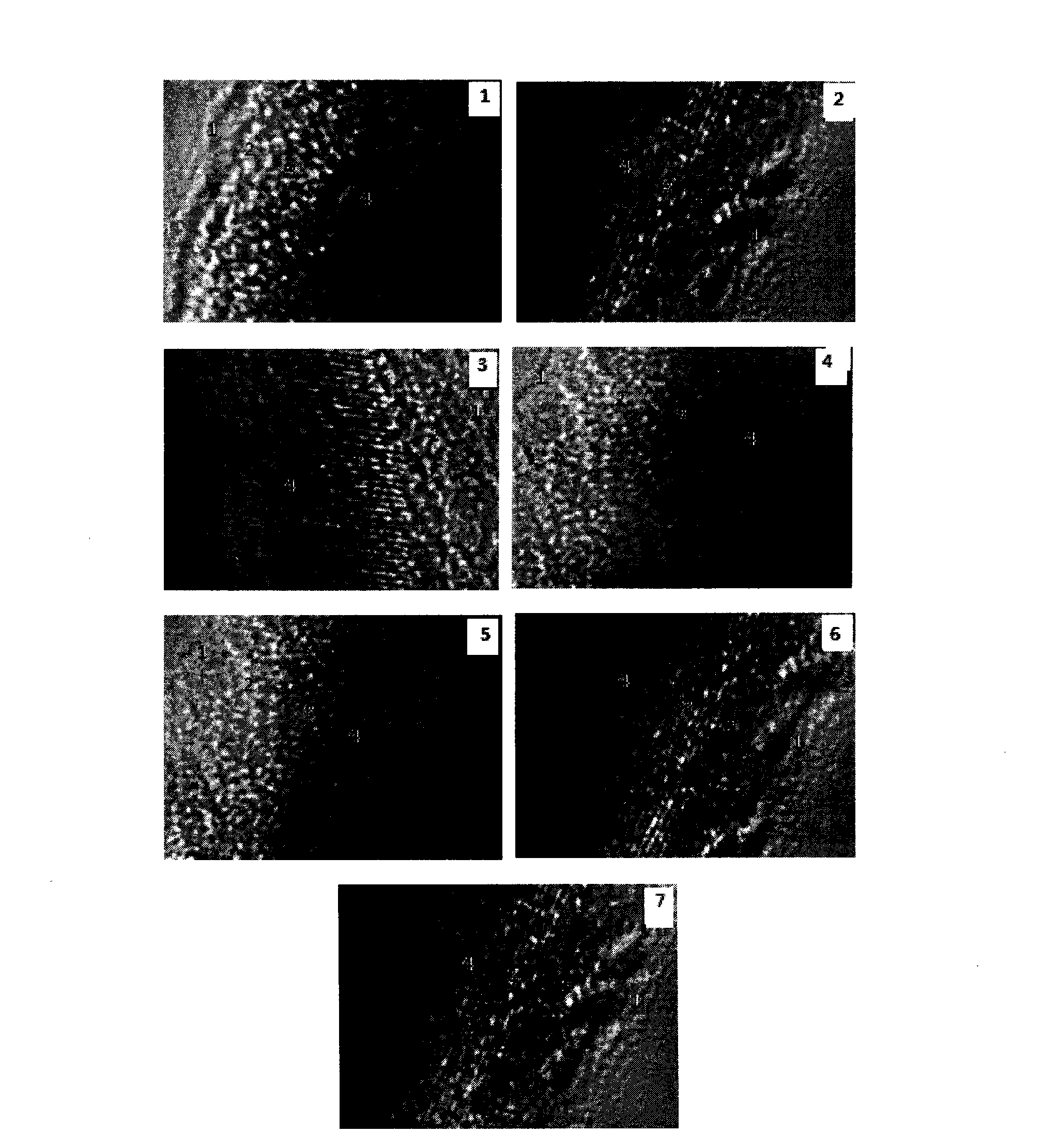

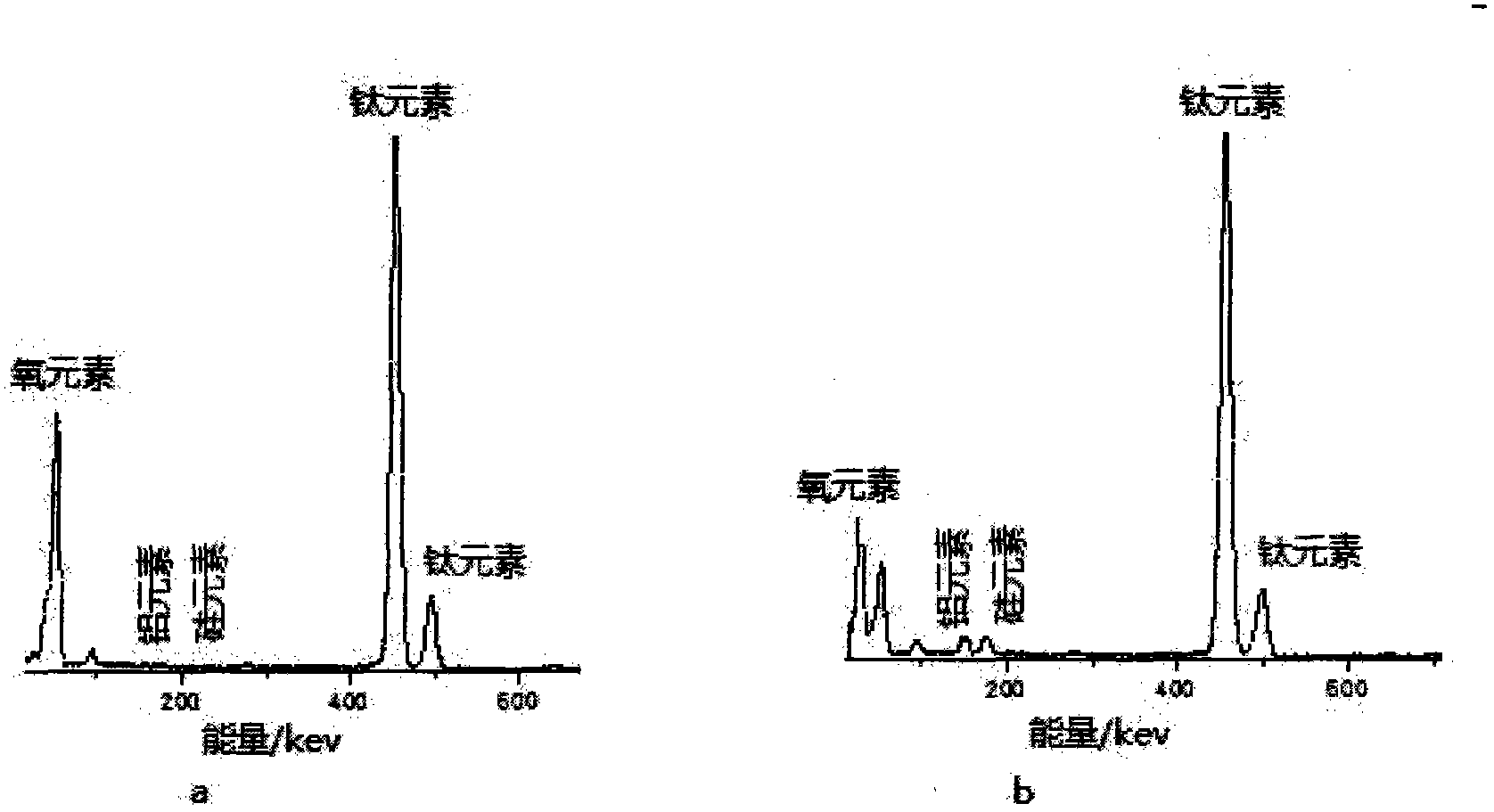

[0016] References [7] The method is to weigh titanium dioxide and add it to a clean volumetric flask, add deionized water to constant volume, then pour the prepared slurry into a four-necked flask and fix the four-necked flask on the iron stand, install the stirring rod and the separator Press the funnel; turn on the power supply, pipette an appropriate amount of sodium hexametaphosphate and add it to the slurry, put the calibrated pH meter into the four-necked flask solution to measure the pH value of the slurry, control the pH value, and turn on the stirrer at the temperature of the water bath Disperse; pipette the coating agent into the constant pressure funnel, and the coating agent in the constant pressure funnel is evenly added dropwise to the reaction slurry. When the coating agent is added dropwise, the pH value is well controlled; Aging at water bath temperature for 2 hours; wrapping zirconium film, aging for 2 hours, then covering silicon film, aging for 2 hours, fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com