Method for simulating radial tire forming process

A radial tire and molding process technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as no tires, minimize product errors, reduce the number of trial productions, and a large amount of information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

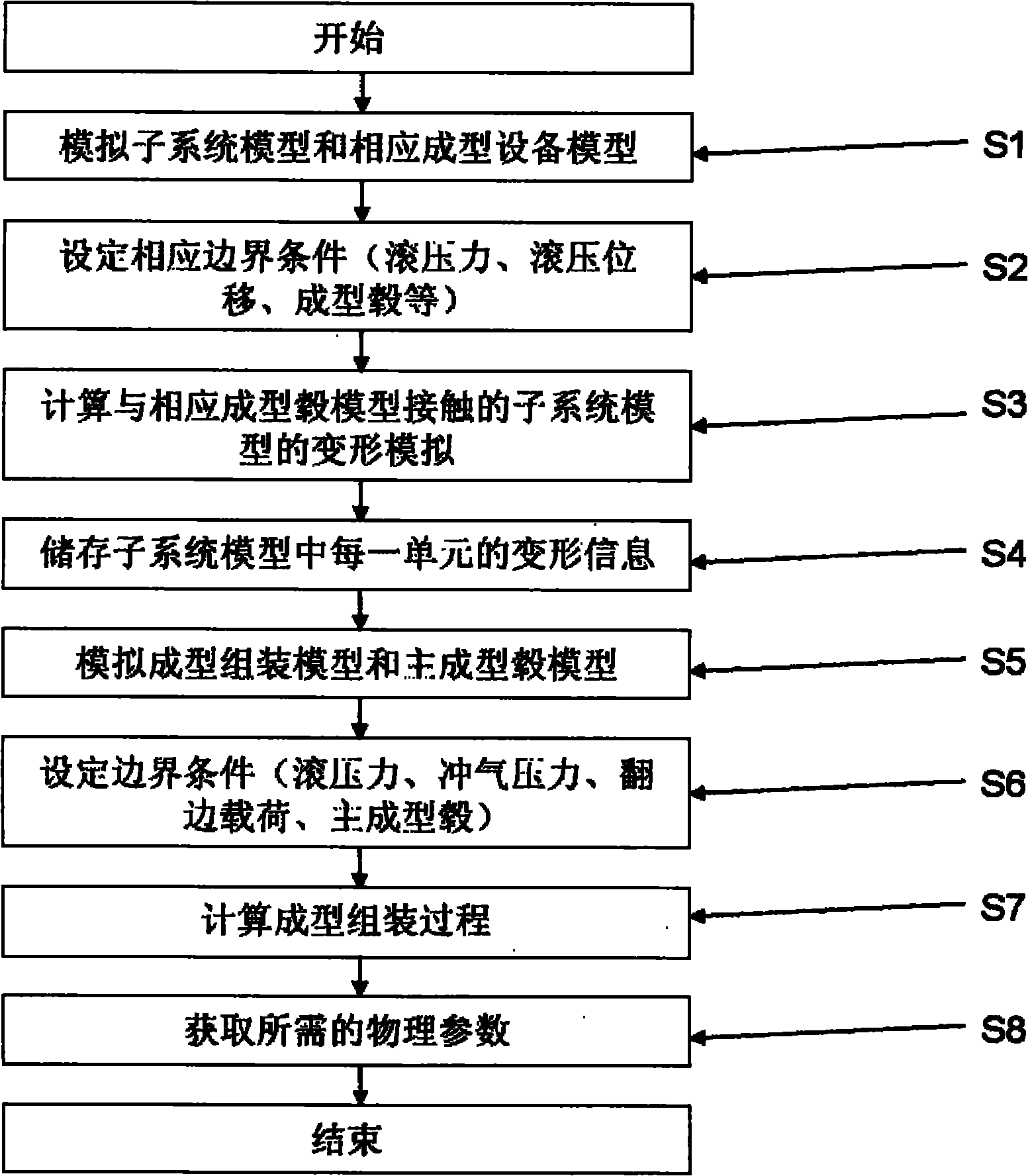

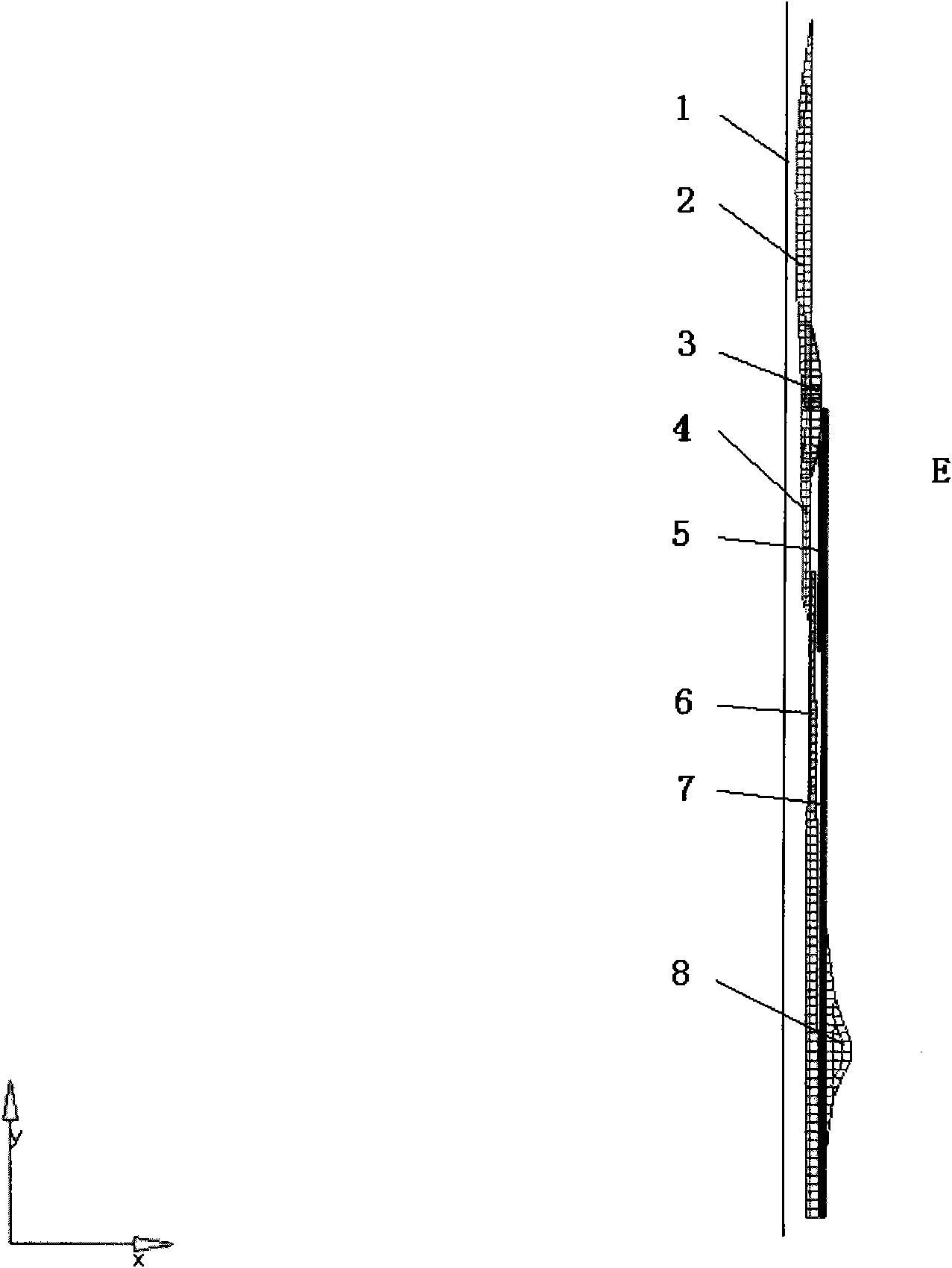

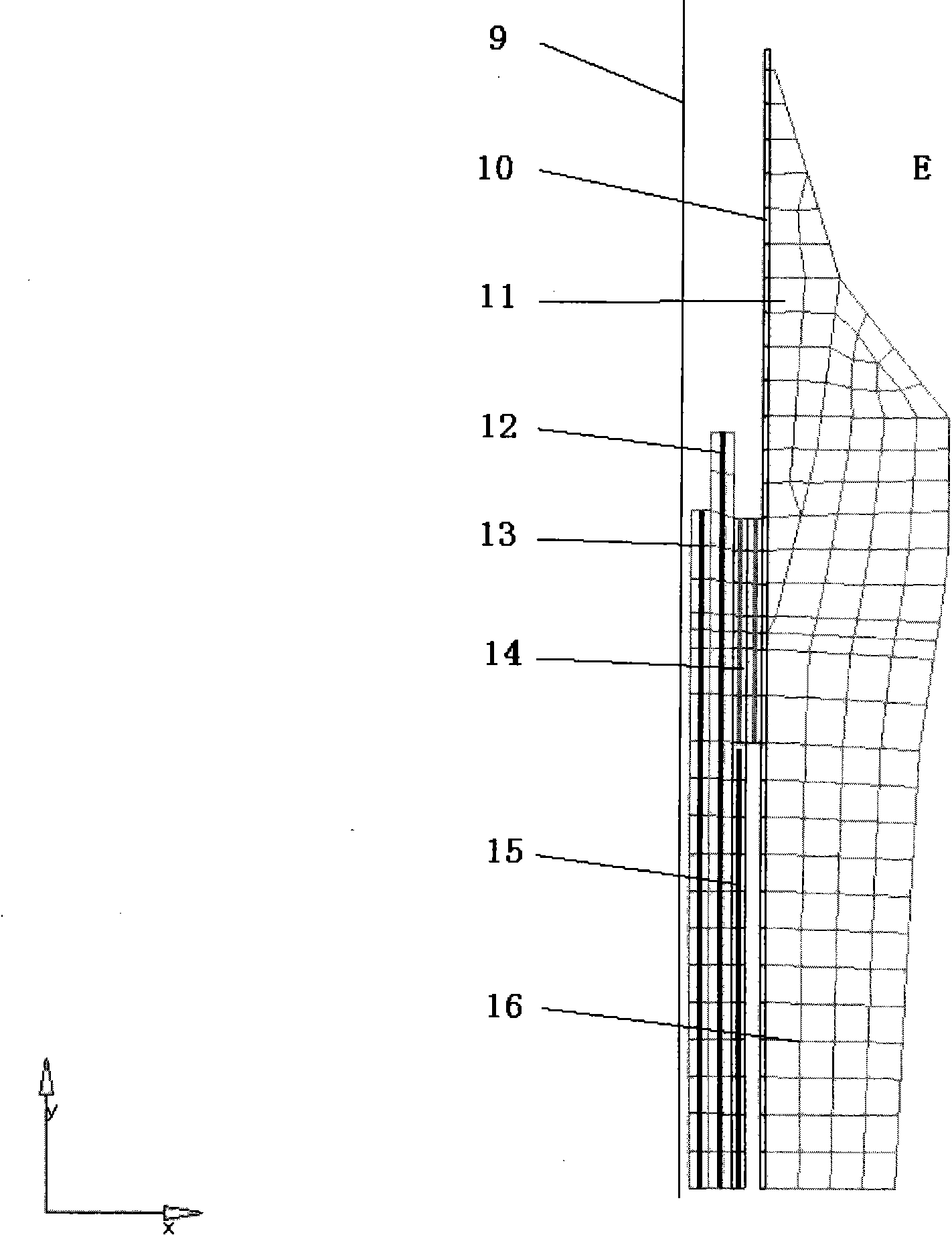

[0023] The invention provides a simulation method for the radial tire building process. figure 1 The flow chart is implemented for the simulation of the radial tire building process according to the present invention. In this embodiment, the first step S1 is to arrange at least one finite element model E (three subsystems, namely the sidewall part, the crown part and the apex part) on the meridian surface of the corresponding forming hub by using the finite element method, so as to Simulate the subsystem model and the corresponding molding equipment model.

[0024] For the finite element model E, the axisymmetric quadrilateral and triangular elements are preferred to simplify the rubber part, the axisymmetric surface elements are preferably used to embed REBAR elements to simplify the cord part, and the axisymmetric rigid elements are preferentially used to simplify the corresponding molded hub part. According to the finite element theory, the physical properties of the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com