Design method of middle blank and prefabricating blank during conical shell forgeable piece forming process

A conical cylinder and forming process technology, applied in the field of forging, can solve the problems of reducing the difficulty of cold working, the inability to guarantee the machining dimensional accuracy, reducing the machining allowance of conical cylinder forgings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

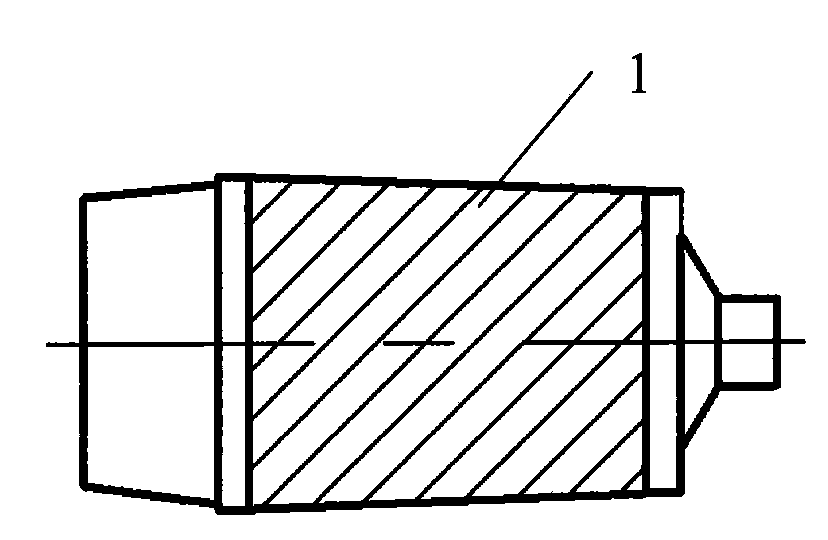

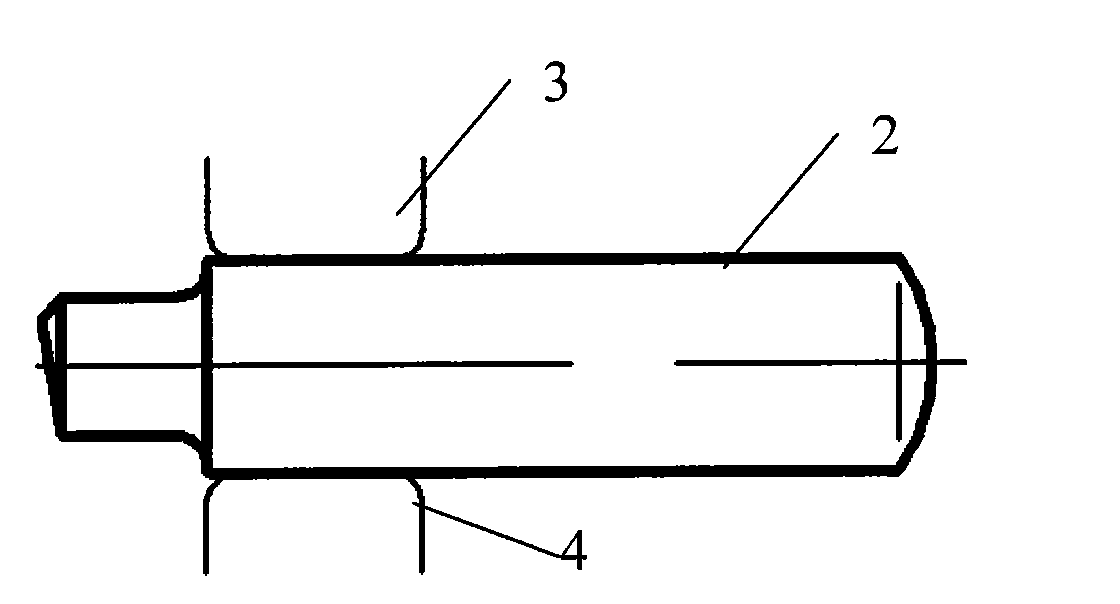

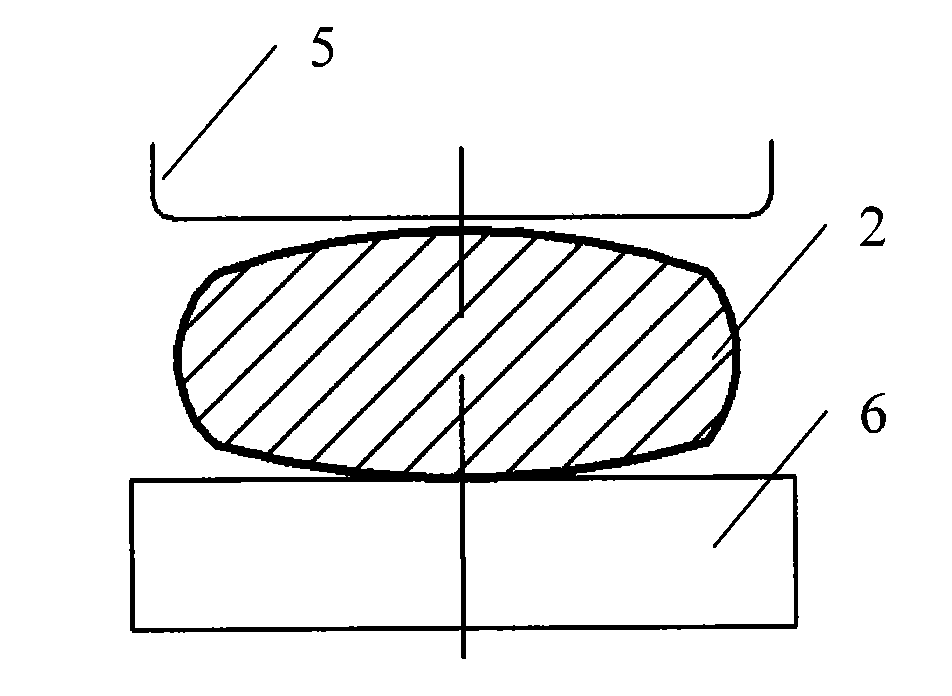

Image

Examples

Embodiment

[0114] The forged part in this embodiment is a pilot test forging of a conical cylinder of a certain type of nuclear power evaporator, and the inner diameter of the large end of the final forging is required to be r 2 =815mm, outer diameter R 2 =1000mm, wall thickness t 2 =185mm, height H 2 =1350mm, taper θ 2 = 11.1°. take k 1 =1.07,k 2 = 1.05, δ = 1.65.

[0115] In the process of reaming from the intermediate billet to the final forging, it can be obtained from the formula (4):

[0116] h 1 =H 2 / k 2 =1350 / 1.05=1286mm

[0117] From formula (12):

[0118] t 1 =δ·t 2 =1.65×185=305mm

[0119] From the formula (6):

[0120] R 1 = t 1 2 + k 2 ( 2 R 2 t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com