Calibration method of detection depth of energy dispersive spectrometer

A technology of detection depth and calibration method, which is applied in the calibration field of energy spectrometer detection depth, and can solve the problem of inability to quantitatively measure the spatial distribution of elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

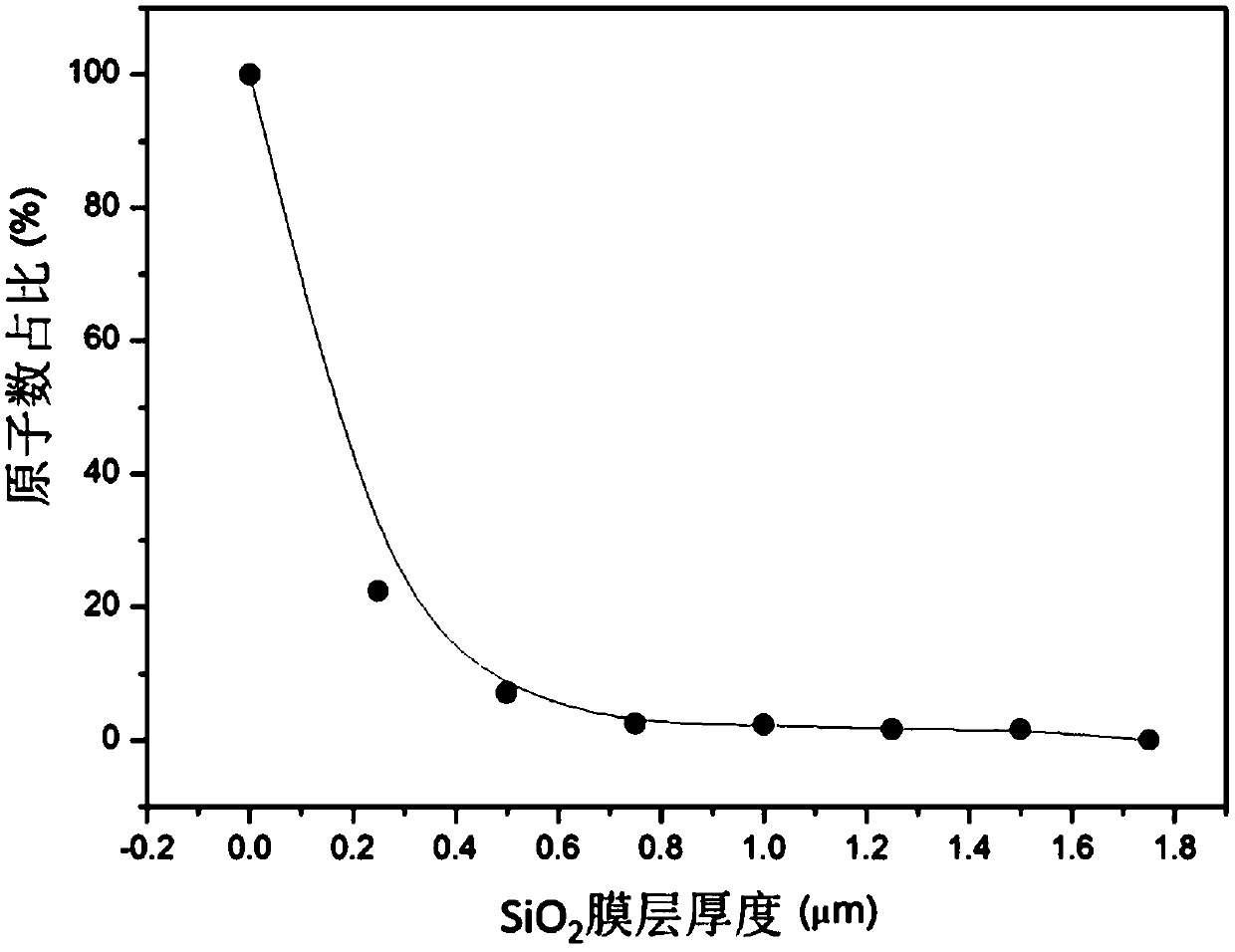

[0039] In the present invention, the proportion of metal elements on the receiving plate is obtained through the energy spectrometer test, and the ratio of the amount of elements reaching the receiving plate after the metal film is damaged and erupted to the total eruption amount is quantitatively calculated.

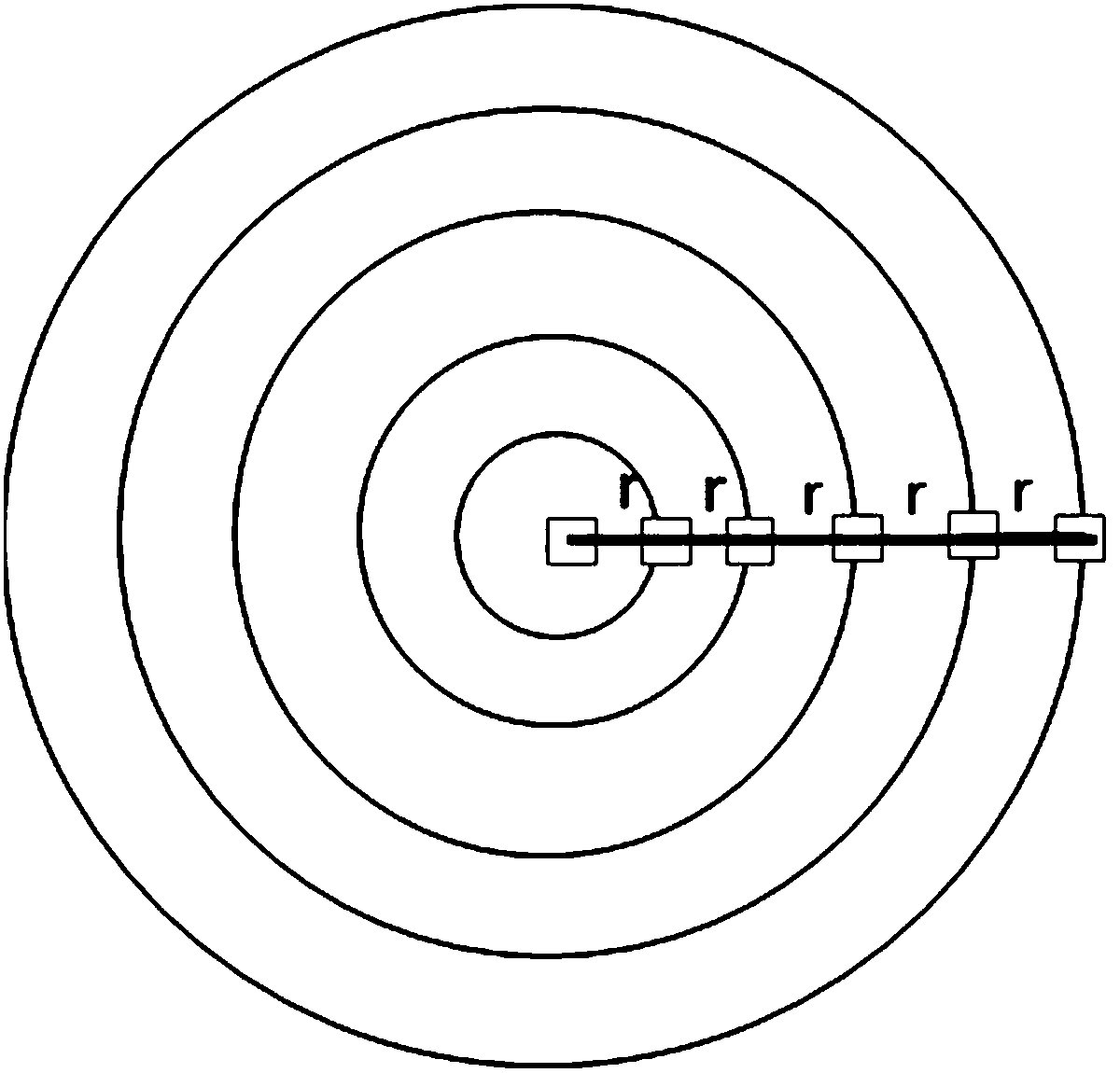

[0040] 1. Calculation model

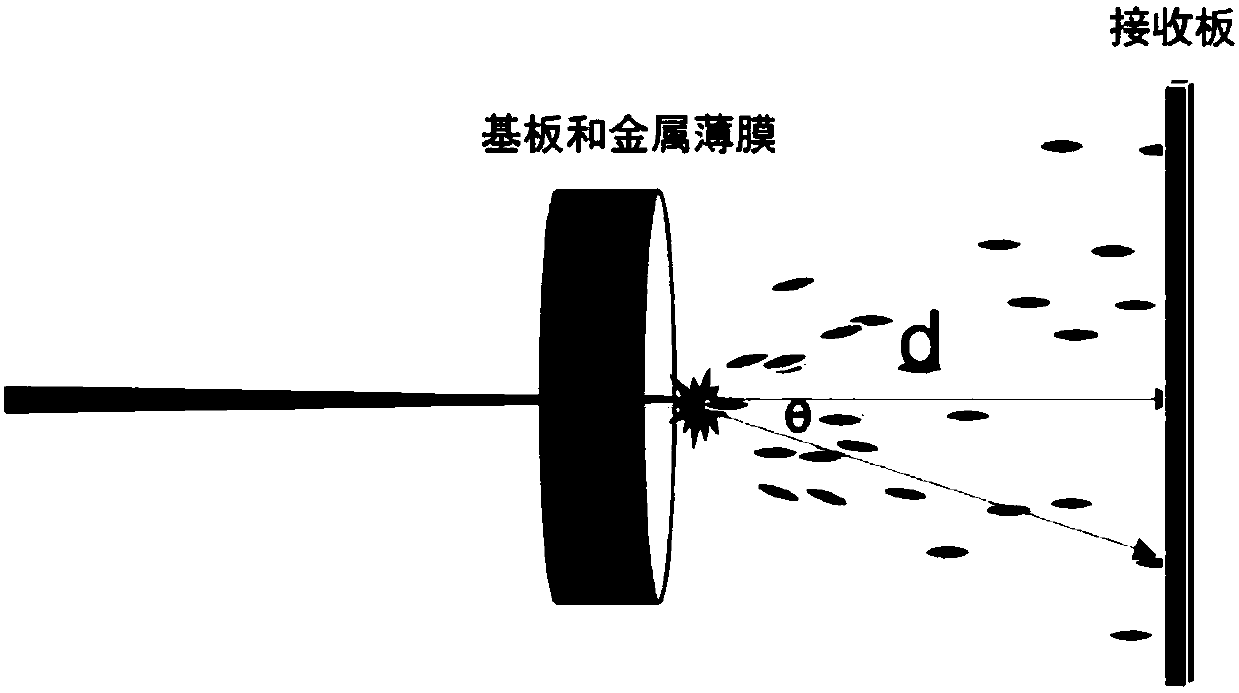

[0041] figure 1 It is a schematic diagram of impurity particle eruption after laser irradiation on the metal film, and the receiving plate can collect the particles erupted by the metal film layer under the action of laser. Such calculations are only for atomic-scale particle morphologies erupted by high-temperature evaporation that cannot be resolved with an optical microscope.

[0042] The proportion of metal elements on the receiving plate obtained by the energy spectrometer test is used to quantitatively calculate the ratio of the amount of elements reaching the receiving plate after the metal film is damaged and erupted to the total e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com