Analytical method for quantitative evaluation of alloy element segregation in high-temperature alloy

A technology for quantitative evaluation of alloy elements, applied in the analysis of materials, material analysis using wave/particle radiation, and measuring devices, etc., can solve problems such as unintuitive results, limited element content, and inability to display element distribution positions, etc., to achieve evaluation Reasonable method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment further illustrate the present invention.

[0021] 1) Thermally mount the 825 alloy sample, use a polishing machine to perform rough grinding with 180#, 800# sandpaper, fine grinding with 1200#, 1500# sandpaper, and then pass through 5μm, 1μm diamond polishing agent, and polish until there is no obvious scratch , quickly washed in absolute ethanol, and dried with a hair dryer;

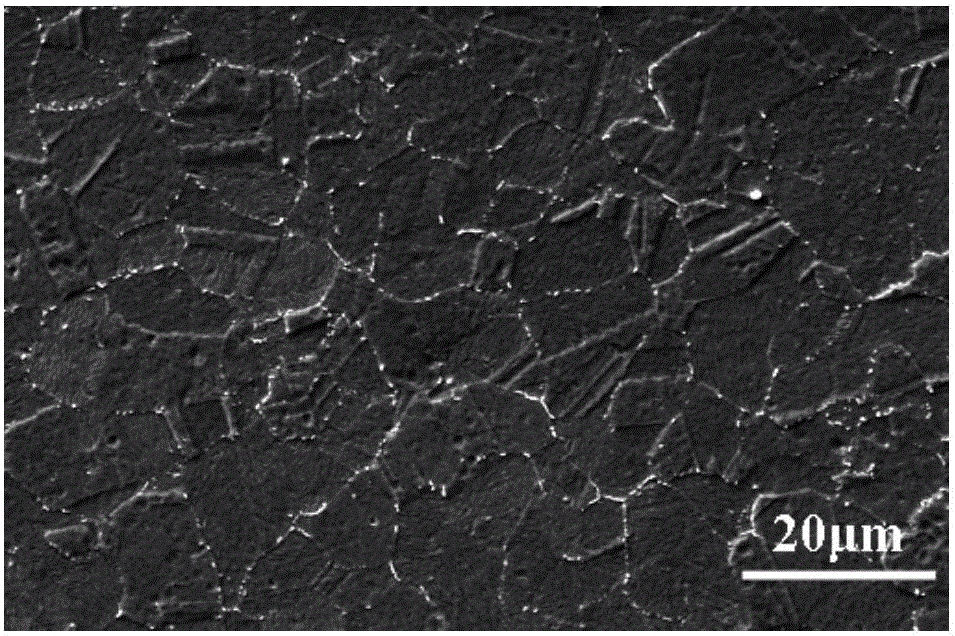

[0022] 2) Dilute copper sulfate, hydrochloric acid, and distilled water according to m CuSO4 :V HCl :V H2O = Prepare the corrosion solution at a ratio of 1:5:5, soak the sample in the solution, and keep the polished surface facing the side wall of the container, observe the surface state of the sample, take out the sample after 2.5 minutes, wash it quickly in absolute ethanol, and use a hair dryer Blow dry, and observe the distribution of the precipitated phase under the scanning electron microscope, such as figure 1 As shown, the white particles are prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com