Preparation method of iron-nickel alloy magnetic layer on surface of stainless steel fiber

A fiber surface, iron-nickel alloy technology, applied in the field of magnetic alloy material preparation, can solve the problems of reduced magnetic permeability, low shielding performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

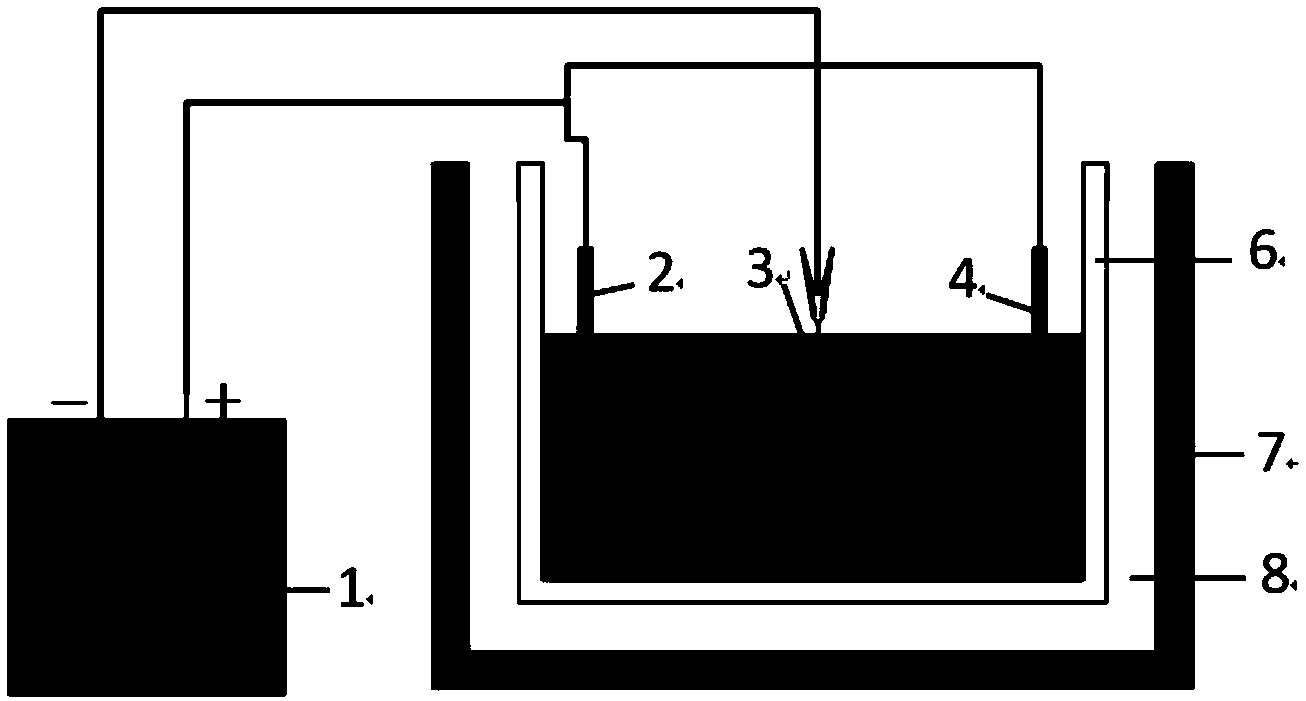

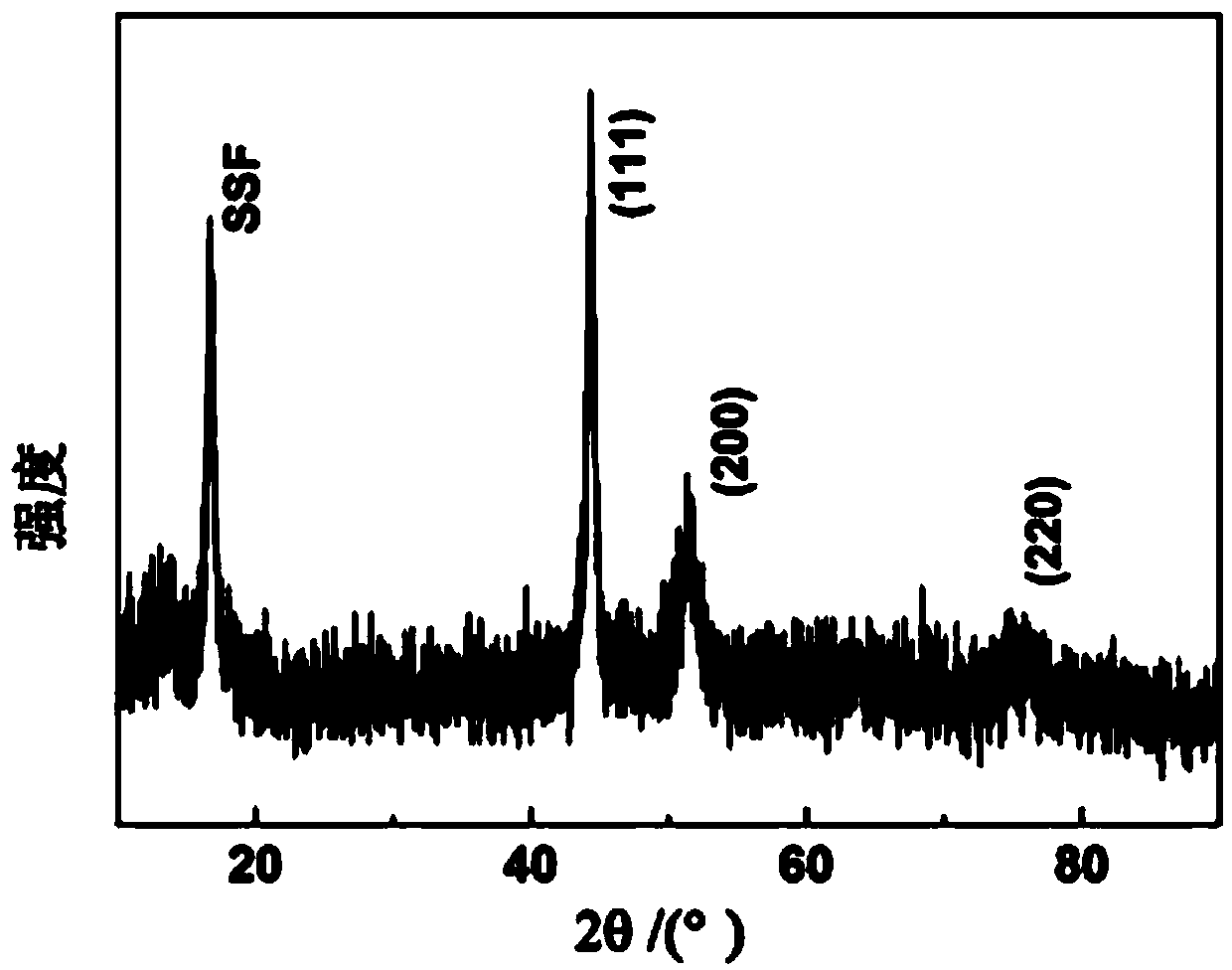

[0022] The preparation method of the electroplating iron-nickel alloy magnetic layer on the surface of the stainless steel fiber mainly comprises: pretreatment of the stainless steel fiber, preparation of the iron-nickel alloy electroplating solution, electroplating of the stainless steel fiber, post-treatment of the electroplating of the stainless steel fiber.

[0023] The iron-nickel alloy electroplating solution used in the present invention is made up according to following component and concentration: nickel sulfate 130~220g / L, nickel chloride 25~60g / L, ferrous sulfate 20~100g / L, sodium citrate 15~30g / L, saccharin 3~5g / L, boric acid 30~50g / L, sodium benzene sulfinate 0.3~0.5g / L; the electroplating solution is prepared according to the following steps: first stir and dissolve nickel sulfate and nickel chloride in 50 Get solution A in deionized water at ~60°C, set aside; then dissolve ferrous sulfate in another beaker at 40°C, pour it into solution A, stir and mix evenly to...

example 1

[0026] The preparation of the iron-nickel alloy magnetic layer electroplated on the surface of stainless steel fiber includes:

[0027] 1. Pretreatment of stainless steel fiber

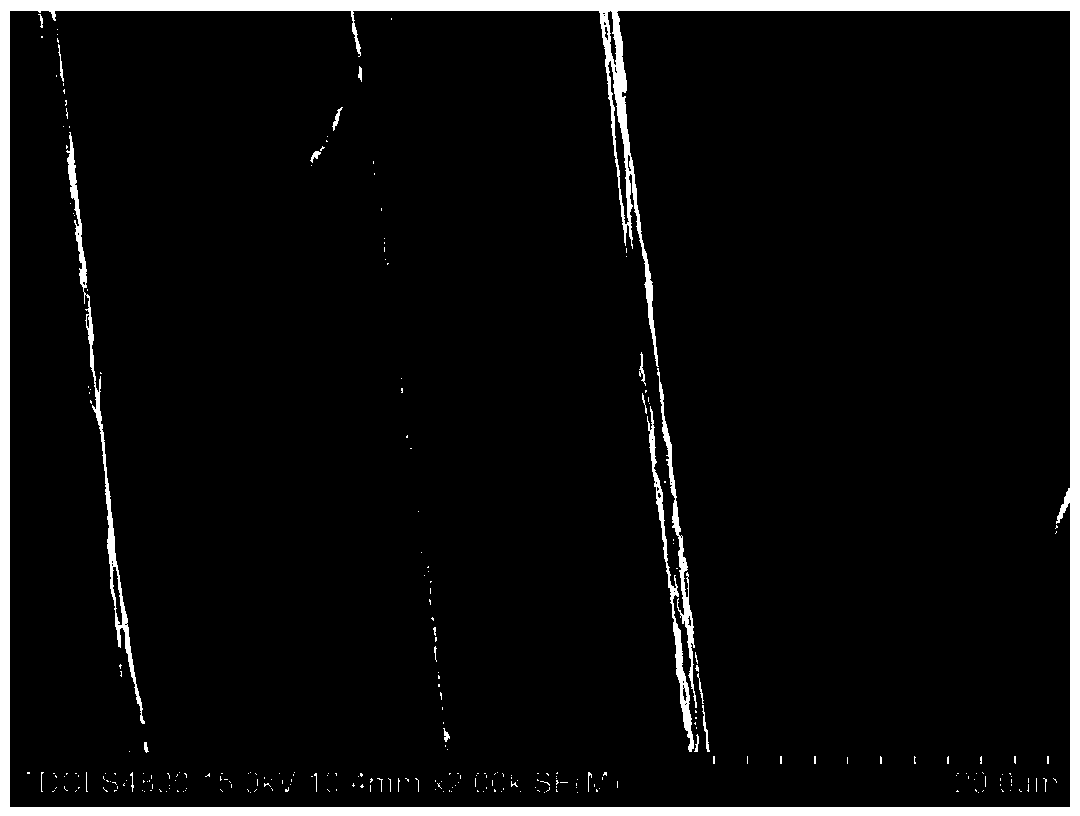

[0028] Cut the 4K stainless steel fiber bundle with a single filament diameter of 11 μm (a bundle of 4000 stainless steel fiber monofilaments) into a length of 5 cm, and place it in absolute ethanol at room temperature for ultrasound (ultrasonic instrument produced by Kunshan Hechuang Ultrasonic Instrument Co., Ltd. , model Kh5200E) for 20 minutes, after ultrasonic cleaning, rinse with deionized water 4 times; then put the rinsed fibers in 60°C NaOH (60g / L) solution for 10 minutes, and then wash them with 40°C and room temperature Rinse 4 times with deionized water; then place the rinsed fiber in HNO at room temperature 3 (80mL / L) solution for ultrasonication for 5 minutes, and finally rinsed with deionized water for 4 times, dried naturally and placed for plating.

[0029] 2. Preparation of electro...

example 2

[0042] The preparation of the iron-nickel alloy magnetic layer electroplated on the surface of stainless steel fiber includes:

[0043] 1. Pretreatment of stainless steel fiber

[0044] Cut the 4K stainless steel fiber bundle with a single filament diameter of 11 μm (a bundle of 4000 stainless steel fiber monofilaments) into a length of 5 cm, and place it in absolute ethanol at room temperature for ultrasound (ultrasonic instrument produced by Kunshan Hechuang Ultrasonic Instrument Co., Ltd. , model Kh5200E) for 20 minutes, after ultrasonic cleaning, rinse with deionized water 4 times; then put the rinsed fibers in 60°C NaOH (60g / L) solution for 10 minutes, and then wash them with 40°C and room temperature Rinse 4 times with deionized water respectively; then ultrasonicate the rinsed fibers in HN 3 (80mL / L) solution at room temperature for 5min, and finally rinse 4 times with deionized water, dry naturally and place to be plated.

[0045] 2. Preparation of iron-nickel alloy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com