Large-plasticity cobalt-based bulk amorphous alloy with high amorphous forming ability and preparing method large-plasticity cobalt-based bulk amorphous alloy

An amorphous alloy and macroplastic technology, applied in the field of cobalt-based bulk amorphous alloy and its preparation, can solve the problems of affecting popularization and application, complex preparation process, poor soft magnetic properties, etc., and achieve improved mechanical properties and excellent mechanical properties. , the effect of reducing the coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2、3 and 4

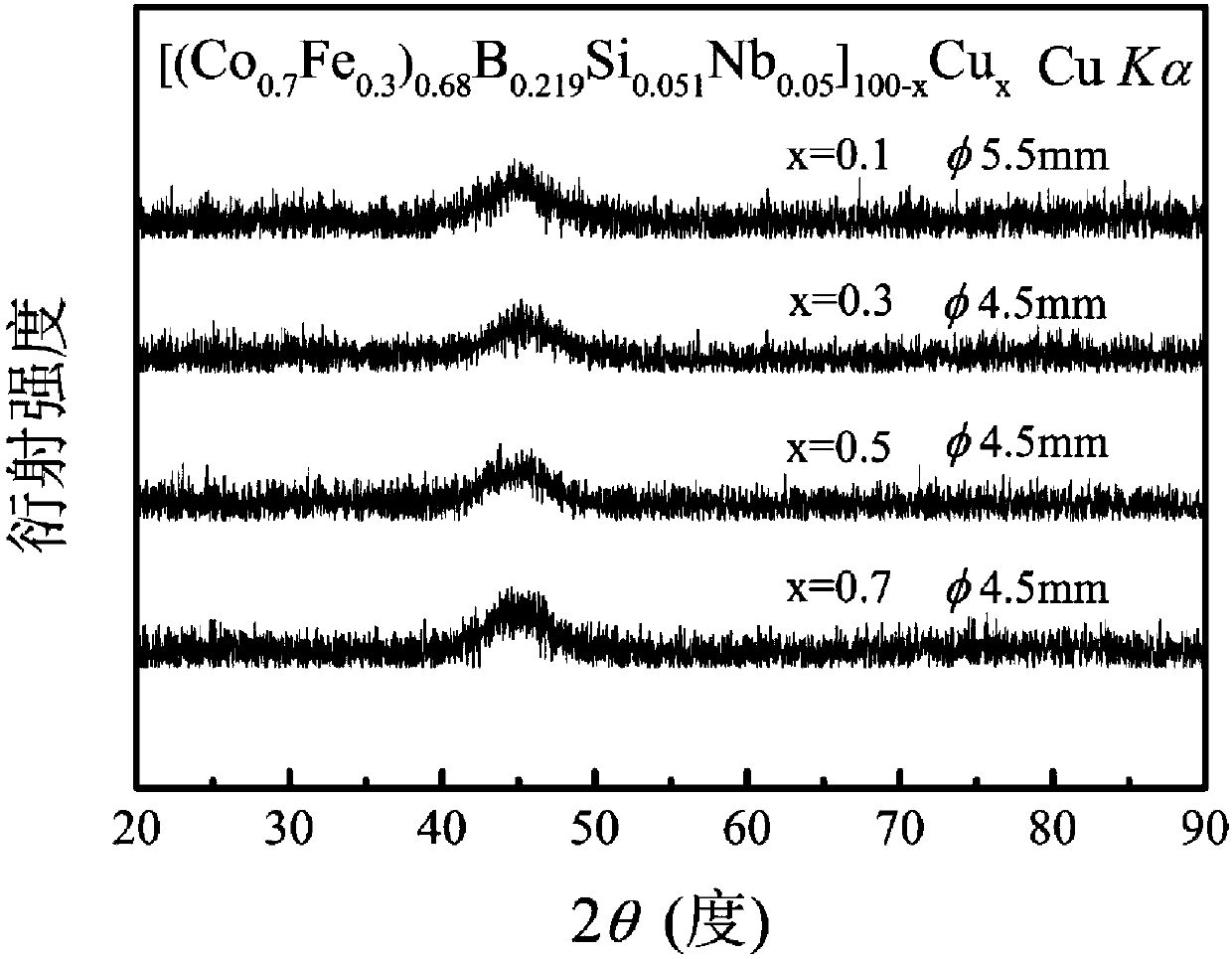

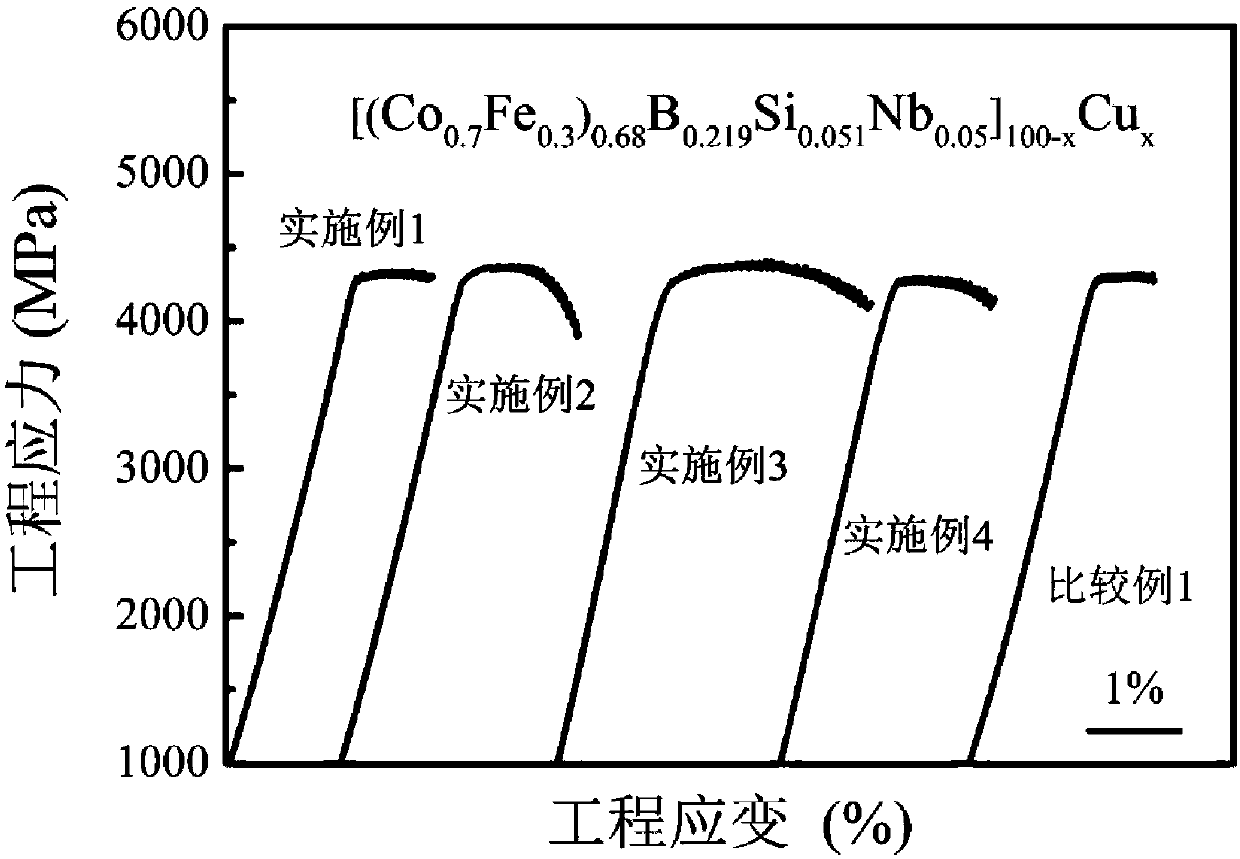

[0038] In one set of embodiments of the present invention, a kind of cobalt base bulk amorphous alloy is provided, and its molecular formula composition satisfies: [(Co 0.7 Fe 0.3 ) 0.68 B 0.219 Si 0.051 Nb 0.05 ] 100-x Cu x , wherein the atomic percentage of Cu element is taken as 0.1, 0.3, 0.5 and 0.7 respectively. The preparation method of the cobalt-based bulk amorphous alloy is as follows:

[0039] Step 1: Co, Fe, B, Si, Nb and Cu elements with a purity of not less than 99% are prepared according to the molecular formula [(Co 0.7 Fe 0.3 ) 0.68 B 0.219 Si 0.051 Nb 0.05 ] 100-x Cu x The atomic percentage in the formula is converted into mass percentage, and the raw materials are prepared;

[0040] Step 2: Put the raw materials prepared in step 1 into the water-cooled copper mold crucible of the arc melting furnace, and first vacuum the cavity to 5×10 -3 Pa, then filled with inert gas to a pressure of 5×10 4 Pa, and then smelting under the protection of an i...

Embodiment 5、6 and 7

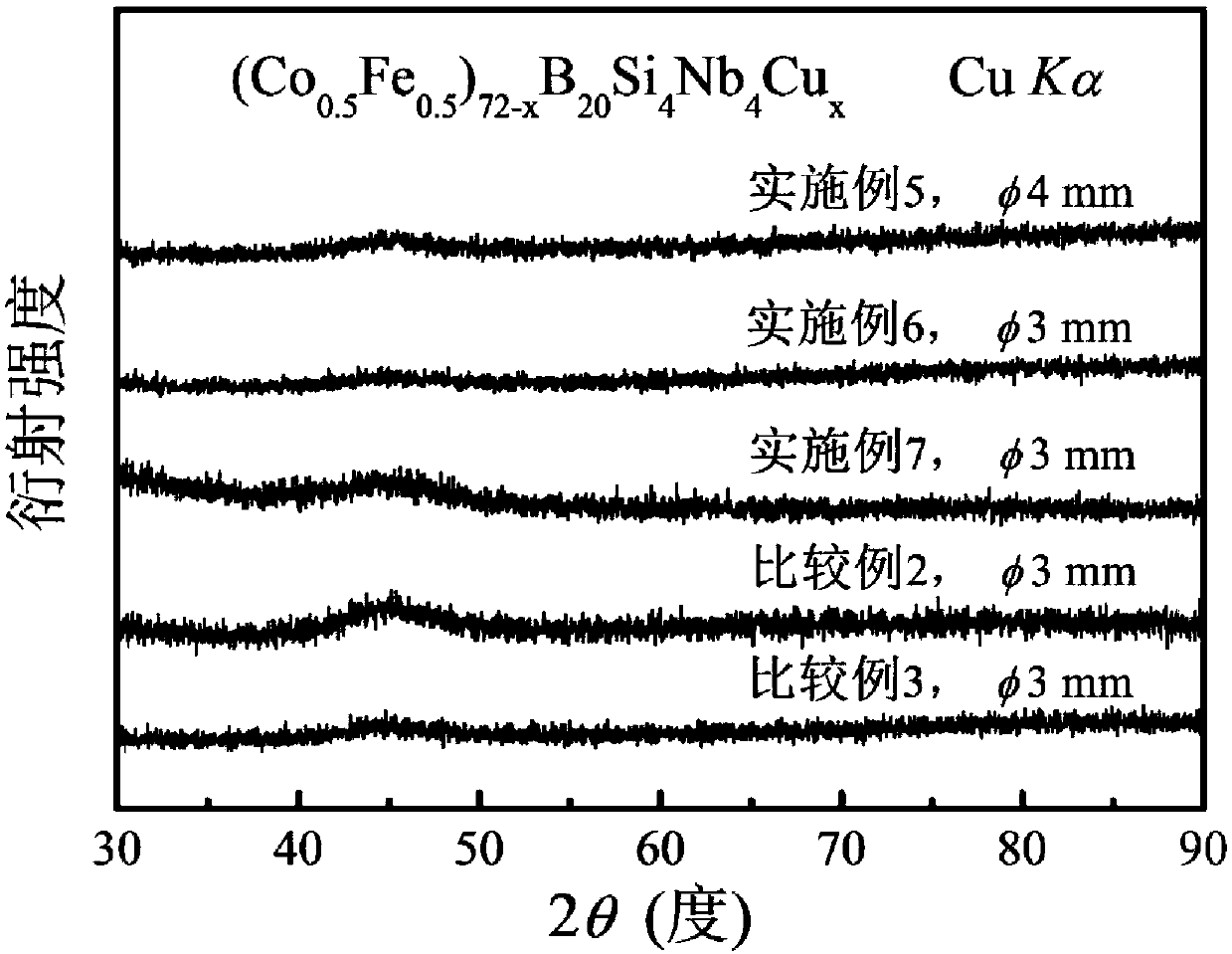

[0056] In another set of embodiments of the present invention, a kind of cobalt base bulk amorphous alloy is provided, and its molecular formula composition satisfies: (Co 0.5 Fe 0.5 ) 72-x B 20 Si 4 Nb 4 Cu x , wherein the atomic percentage of Cu element is taken as 0.3, 0.4 and 0.7 respectively. The preparation method of the cobalt-based bulk amorphous alloy is as follows:

[0057] Step 1: Co, Fe, B, Si, Nb and Cu elements with a purity of not less than 99% are prepared according to the molecular formula (Co 0.5 Fe 0.5 ) 72- x B 20 Si 4 Nb 4 Cu x The atomic percentage in the formula is converted into mass percentage, and the raw materials are prepared;

[0058] Step 2: Put the raw materials prepared in step 1 into the water-cooled copper mold crucible of the arc melting furnace, and first vacuum the cavity to 5×10 -3 Pa, then filled with inert gas to a pressure of 5×10 4 Pa, and then smelting under the protection of an inert atmosphere. After the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com