Patents

Literature

31results about How to "Improve compression plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

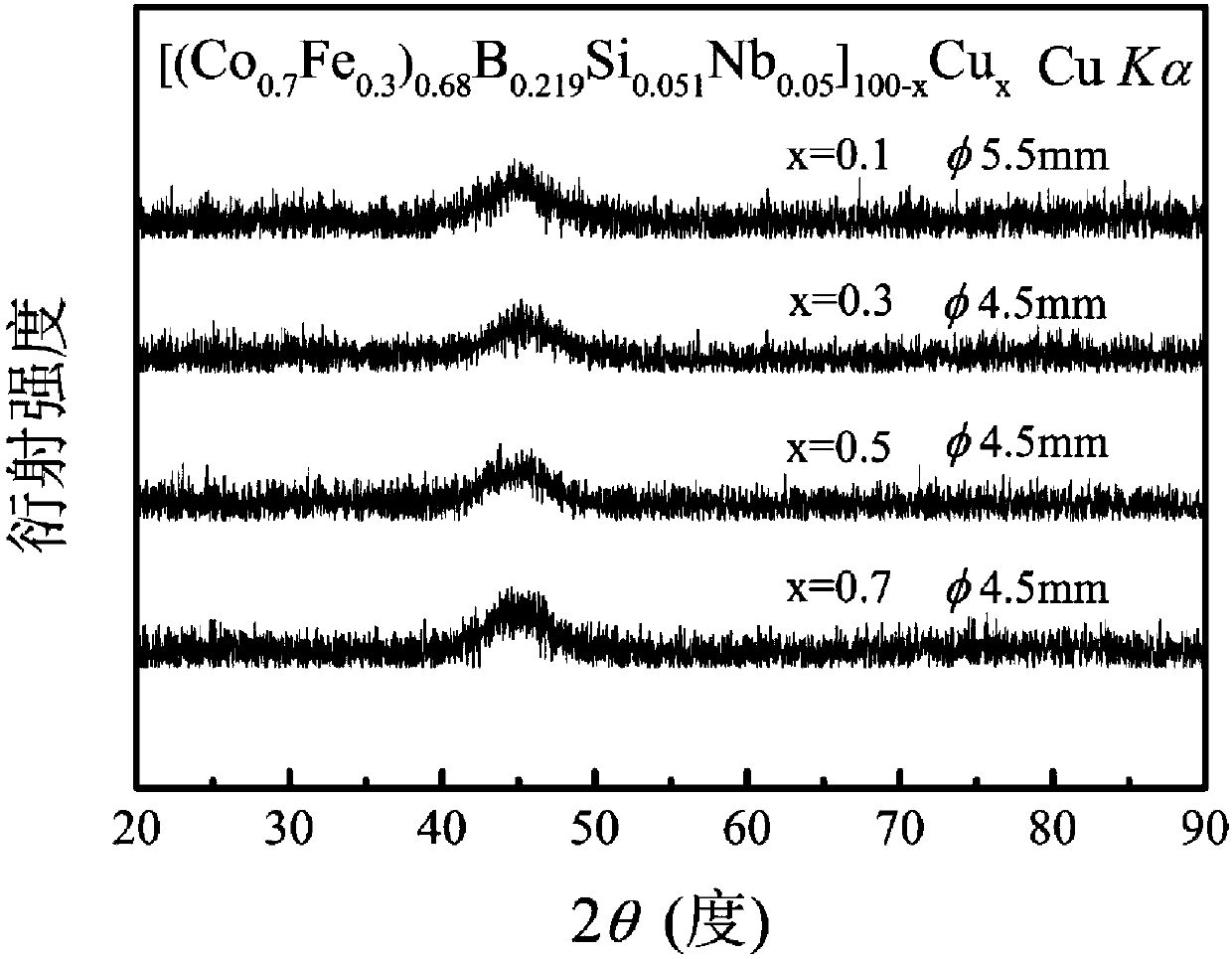

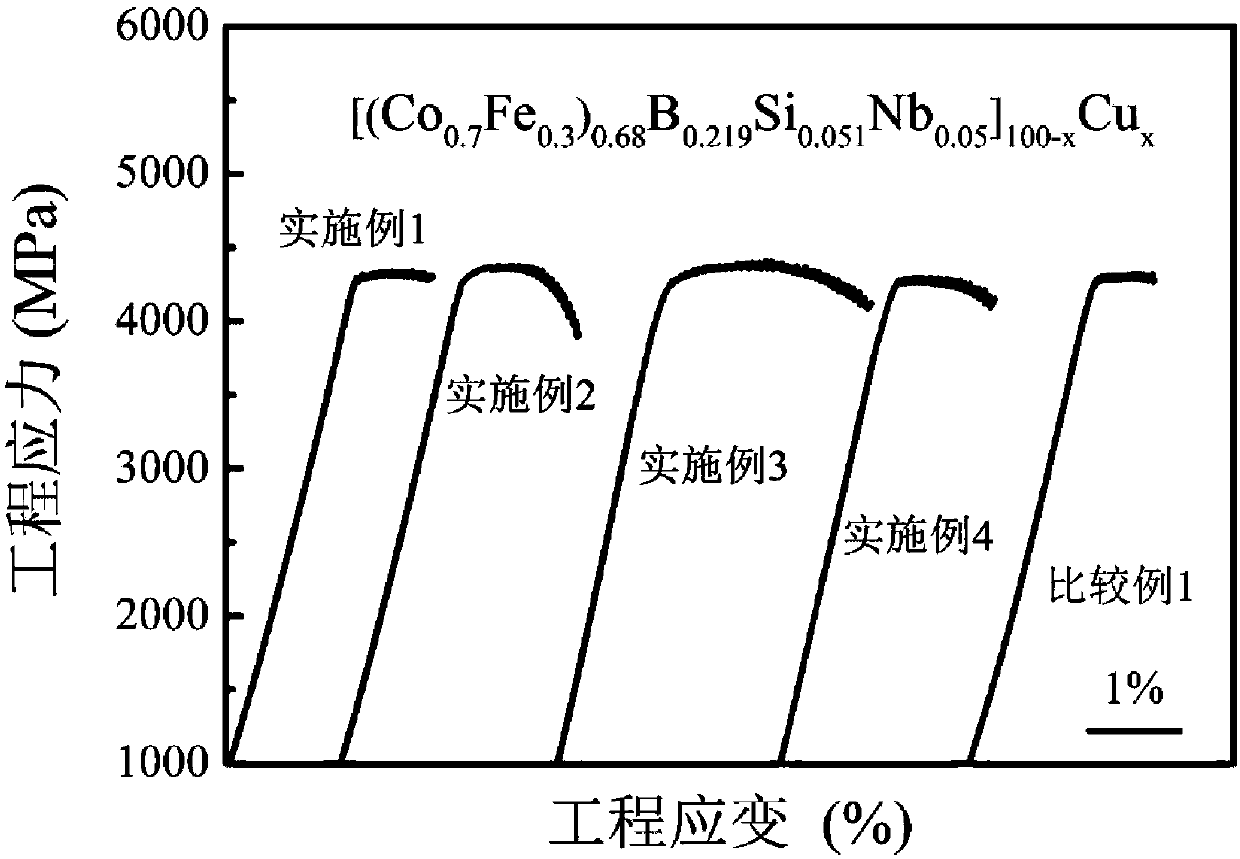

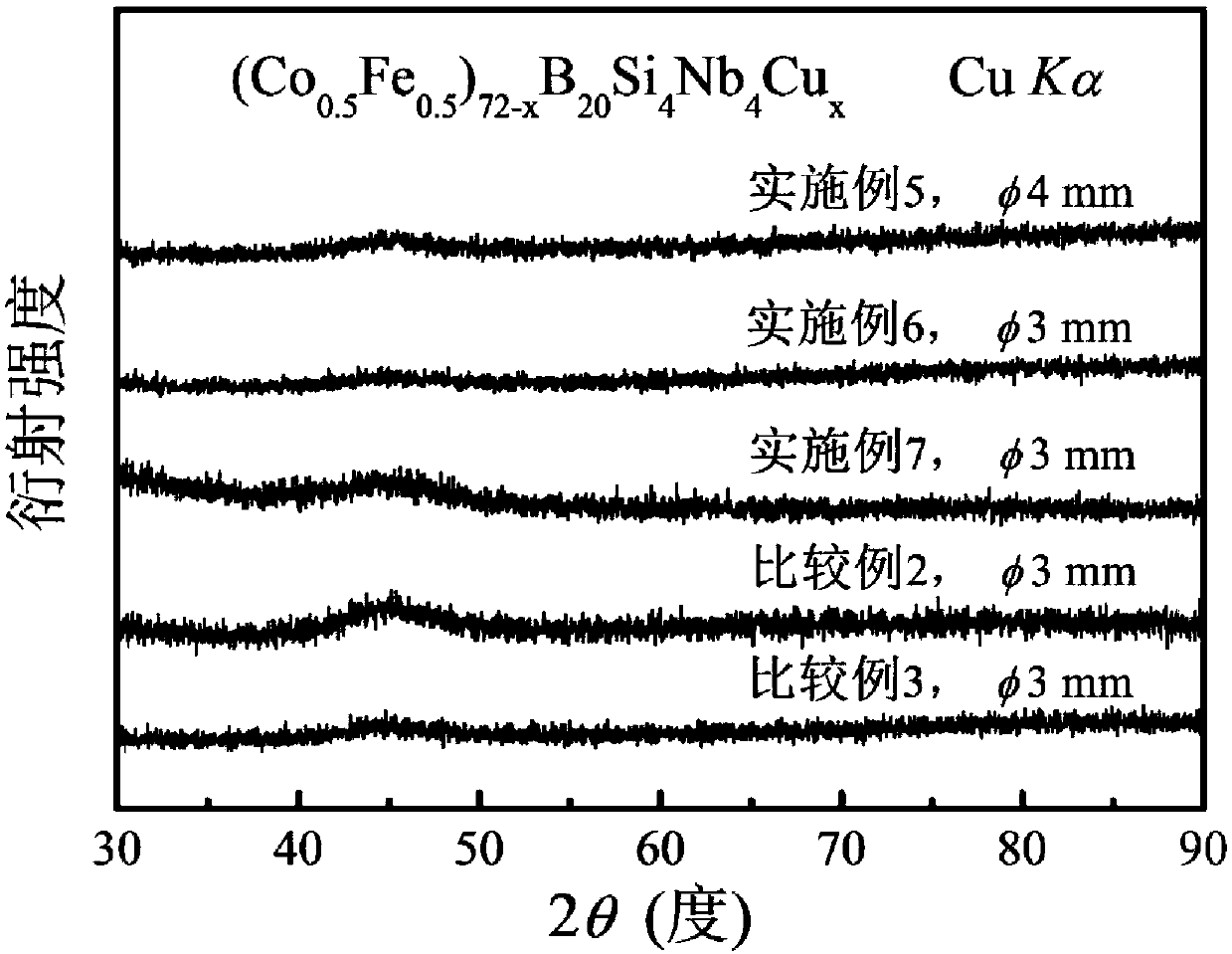

Large-plasticity cobalt-based bulk amorphous alloy with high amorphous forming ability and preparing method large-plasticity cobalt-based bulk amorphous alloy

InactiveCN107829047AStrong ability to inhibit crystallizationImprove thermal stabilityBreaking strengthRare-earth element

The invention provides a large-plasticity cobalt-based bulk amorphous alloy with high amorphous forming ability. The molecular formula of the bulk amorphous alloy is CoaFebBxSiyNbcCud, in the formula,a, b, c, d, x and y show atomic percents of corresponding alloying elements, wherein a is larger than or equal to 35 and smaller than or equal to 48, b is larger than or equal to 20 and smaller thanor equal to 36, c is larger than or equal to 4 and smaller than or equal to 5, d is larger than or equal to 0.1 and smaller than or equal to 0.9, x is larger than or equal to 20 and smaller than or equal to 24, y is larger than or equal to 4 and smaller than or equal to 5.5, a+b is larger than or equal to 65 and smaller than or equal to 71.9, and a+b+c+d+x+y is equal to 100. Compared with the prior art, the alloy has the obviously beneficial effects that the high amorphous forming ability, the outstanding plastic deformation capacity and the excellent soft magnetic property are achieved, the maximum critical diameter reaches 3 mm-5.5 mm, the breaking strength is 4060 MPa-4400 MPa, the plastic deformation capacity is 1%-3.7%, the saturation magnetization is 0.72 T and above, and the coercive force is 0.81A / m-1.41 A / m; and the alloy does not contain rare earth elements and easy volatile elements, the preparing process is simple, and the good application prospect is achieved. The invention further provides a preparing method of the above alloy.

Owner:SOUTHEAST UNIV

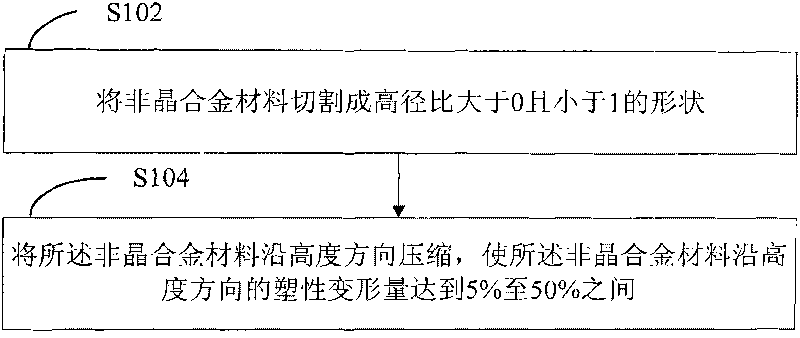

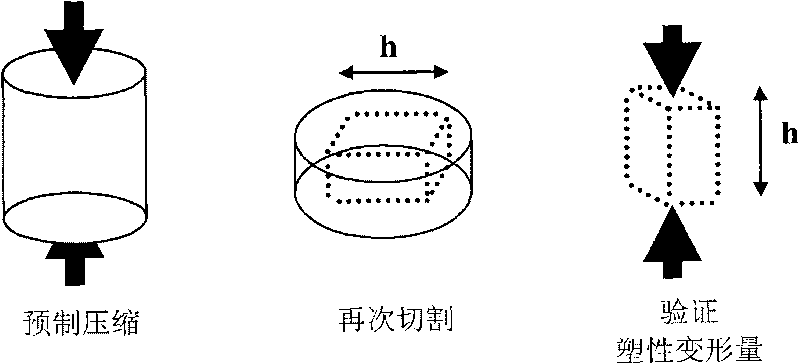

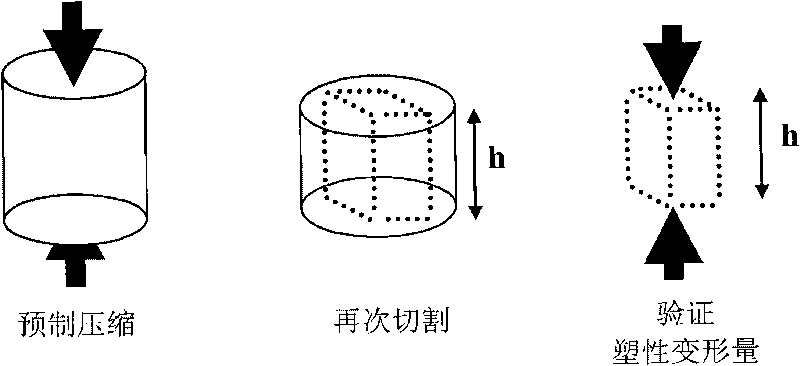

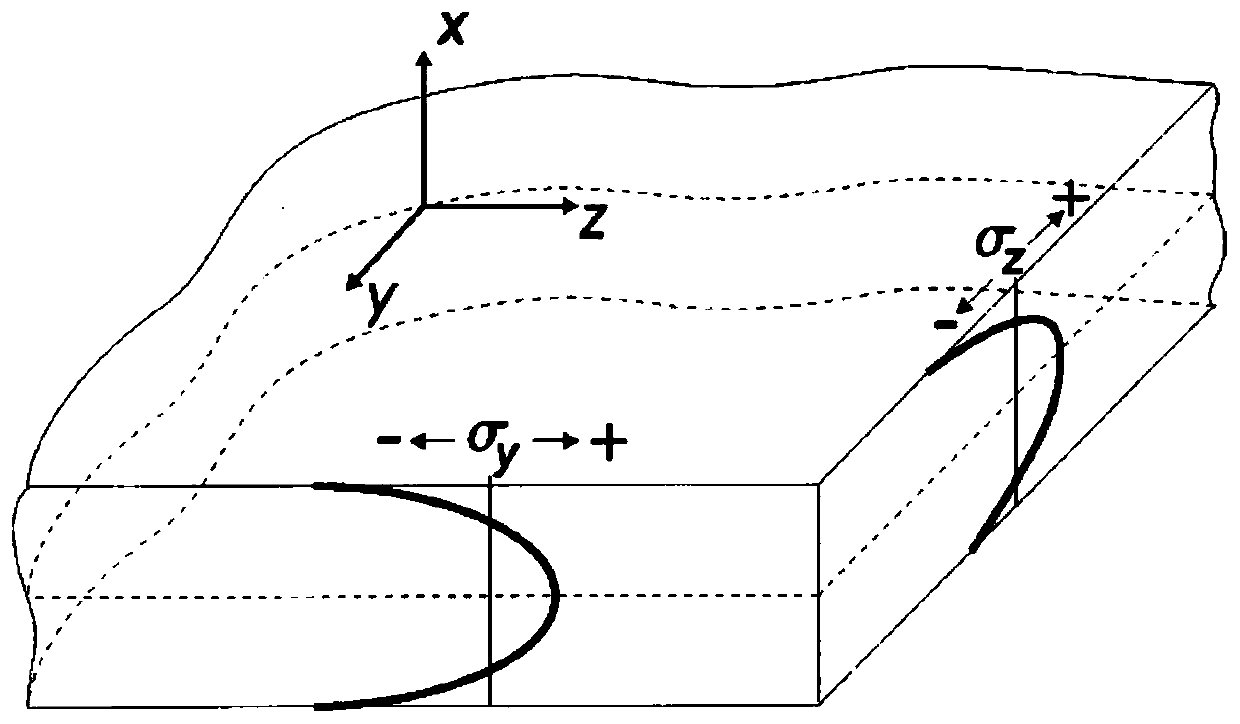

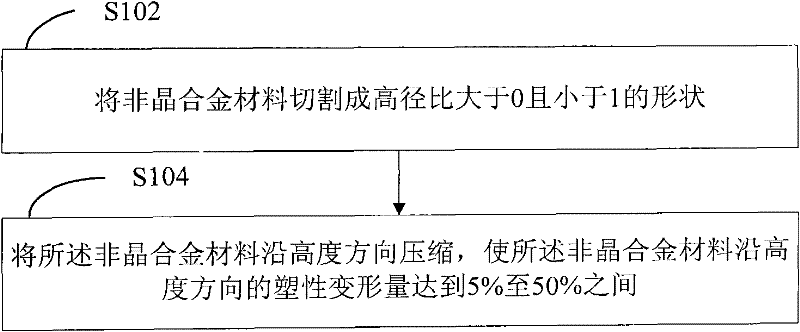

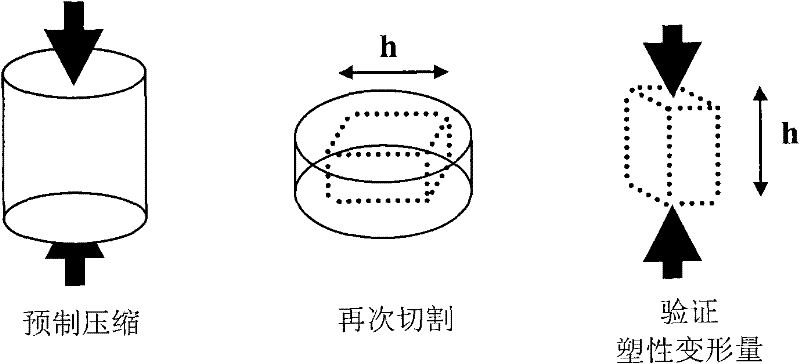

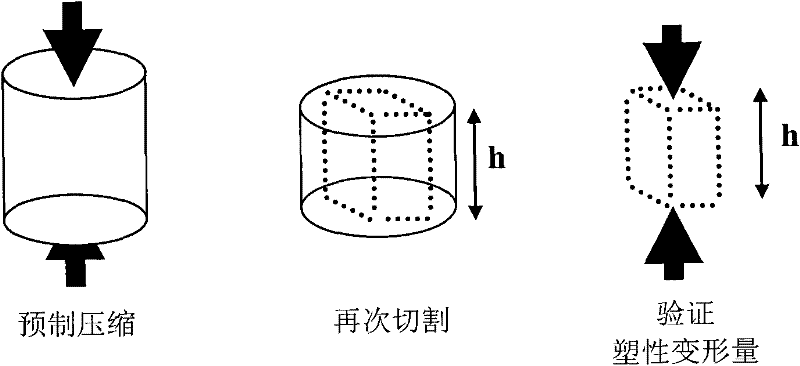

Method and system for improving compression plasticity of amorphous alloy

InactiveCN101717902AImprove compression plasticityImprove plastic deformation abilityDiameter ratioDistortion

The invention provides a method and a system for improving the compression plasticity of amorphous alloy. The method for improving the compression plasticity of the amorphous alloy comprises the following steps of: cutting an amorphous alloy material to be in a shape of which the height-diameter ratio is larger than 0 and smaller than 1; and compressing the amorphous alloy material along the height direction so that the plastic distortion of the amorphous alloy material along the height direction reaches 5 percent to 50 percent. The method and the system for improving the compression plasticity of the amorphous alloy can improve the plastic distortion capability of the amorphous alloy material, lead the amorphous alloy material to also have larger compression plasticity at the standard height-diameter ratio, and are simpler to realize without complicated process.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

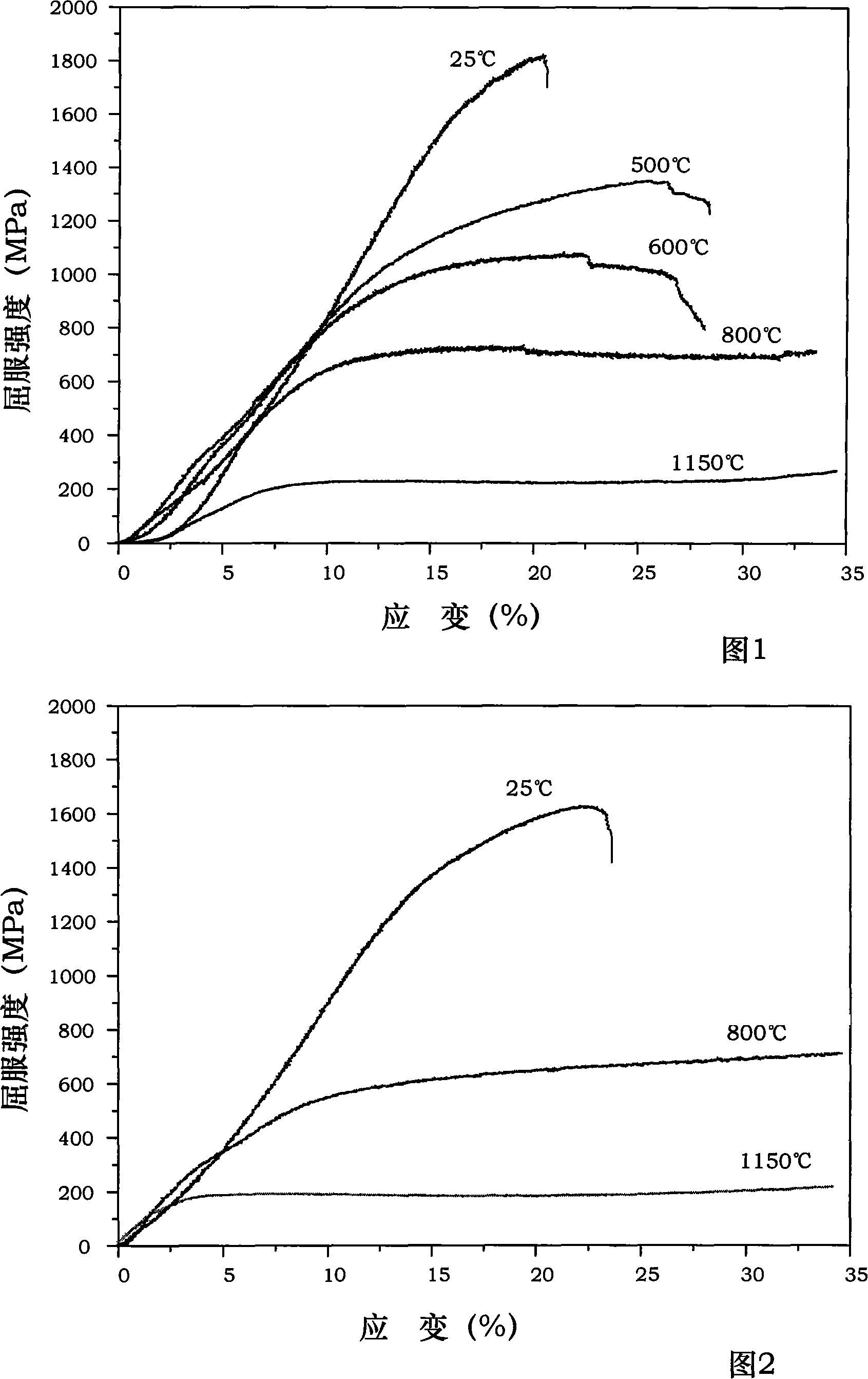

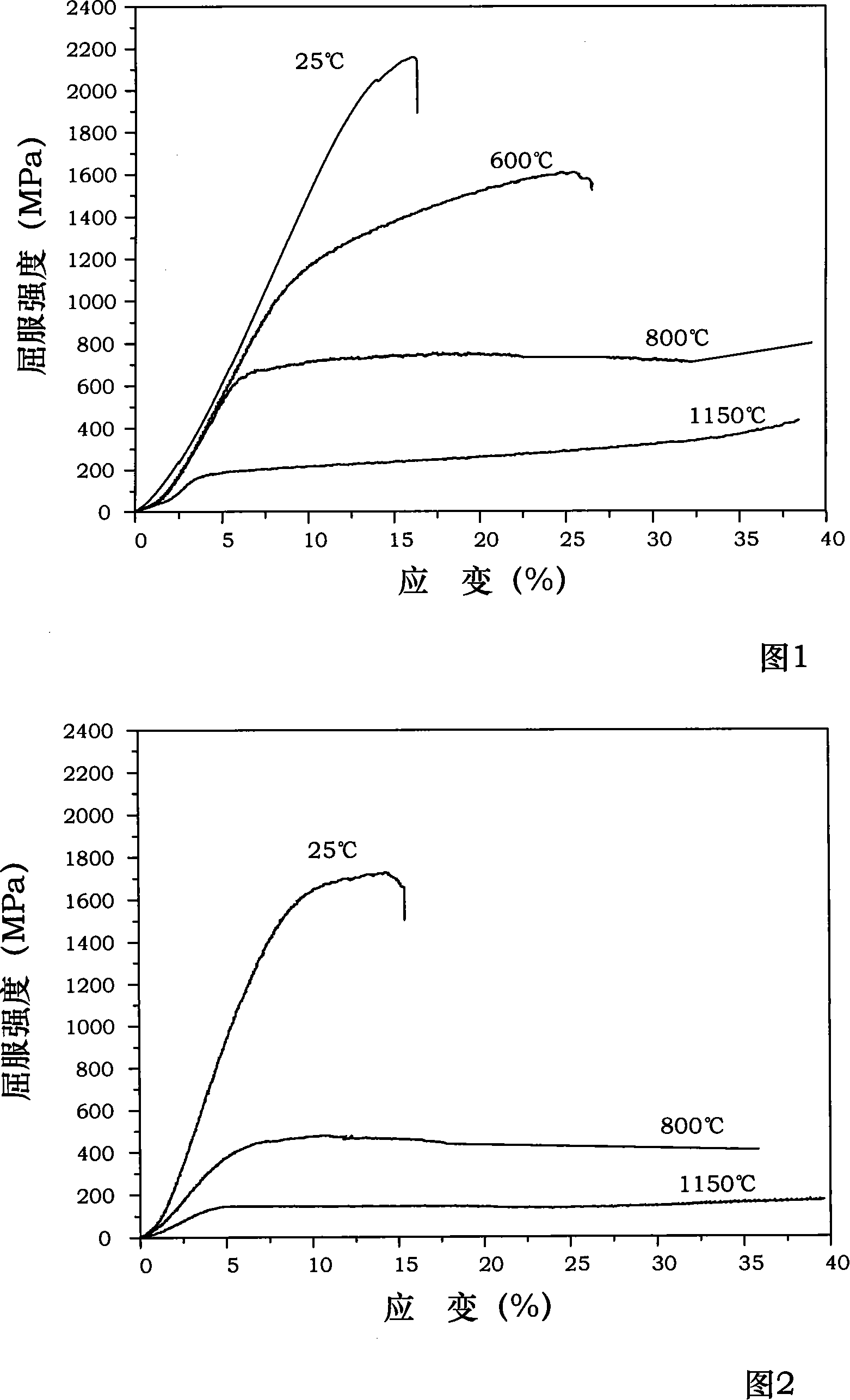

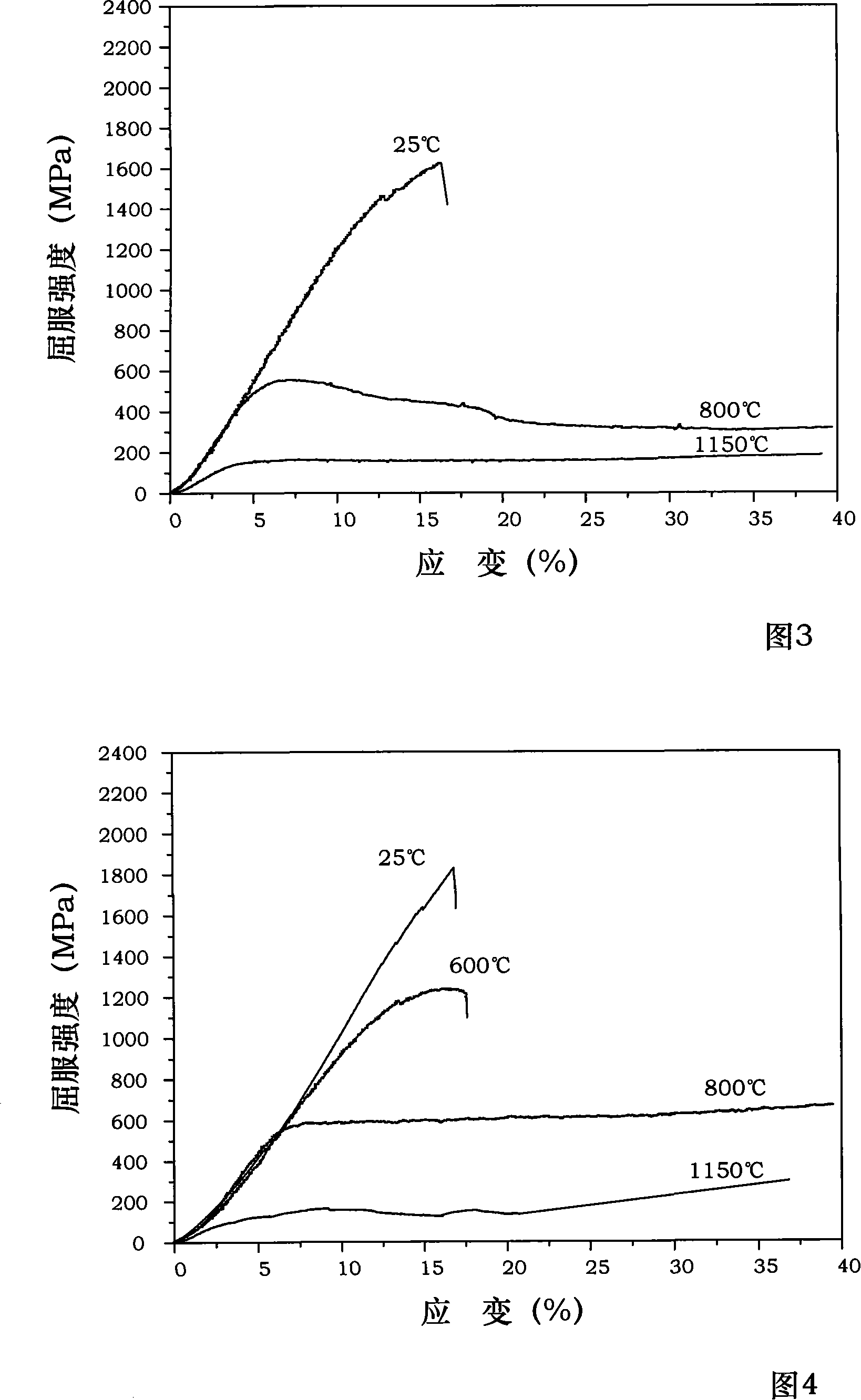

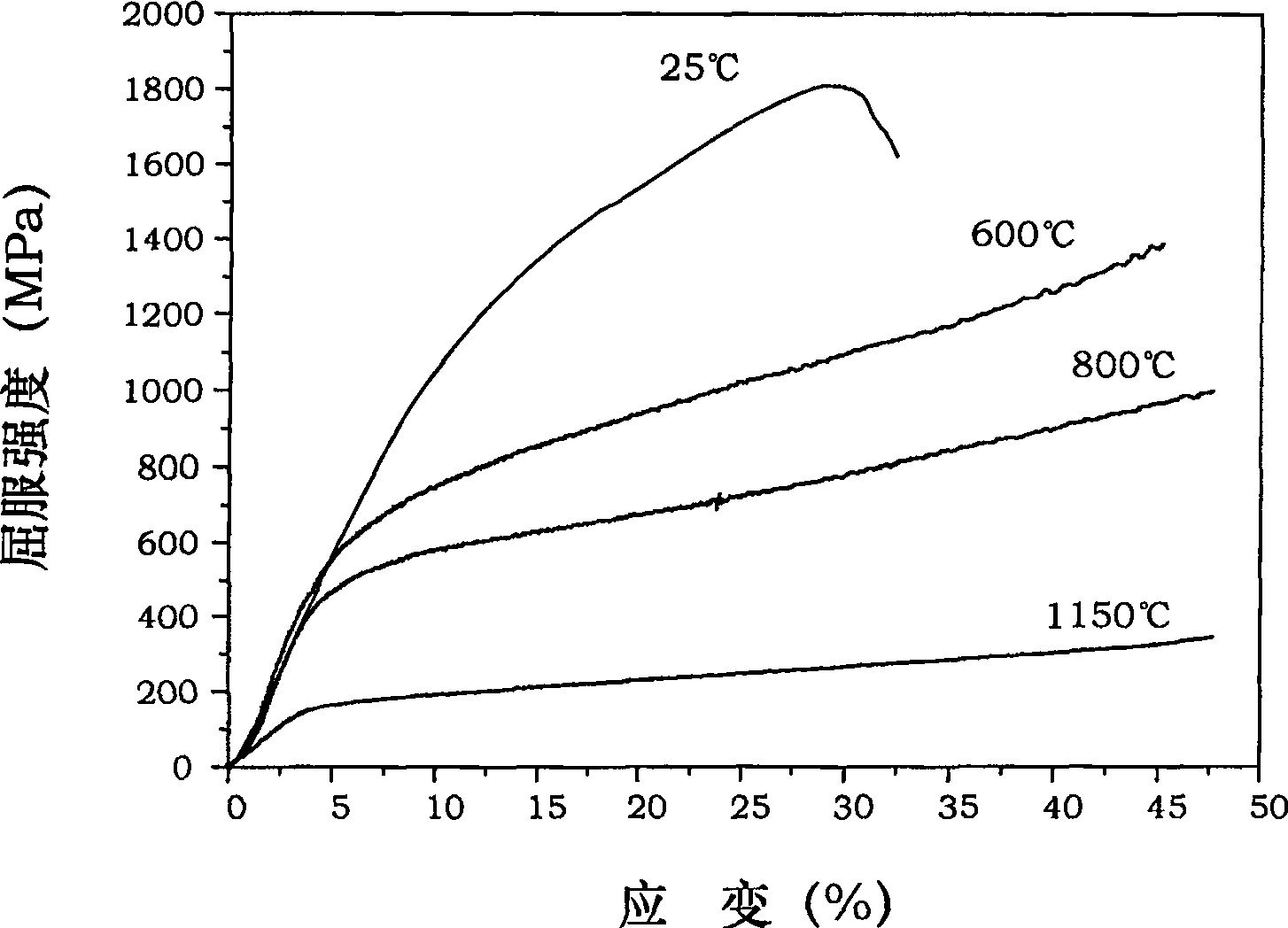

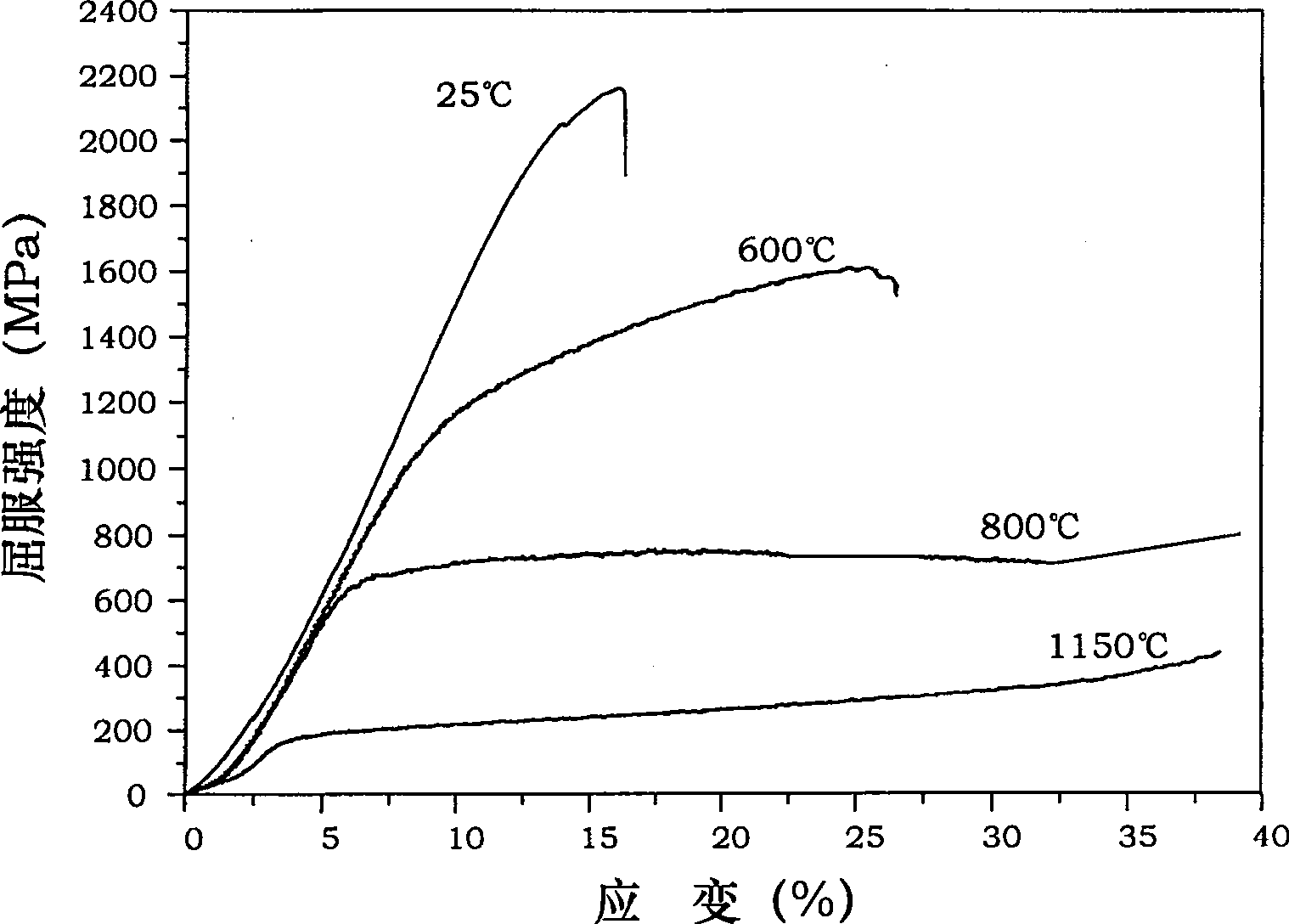

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Ta

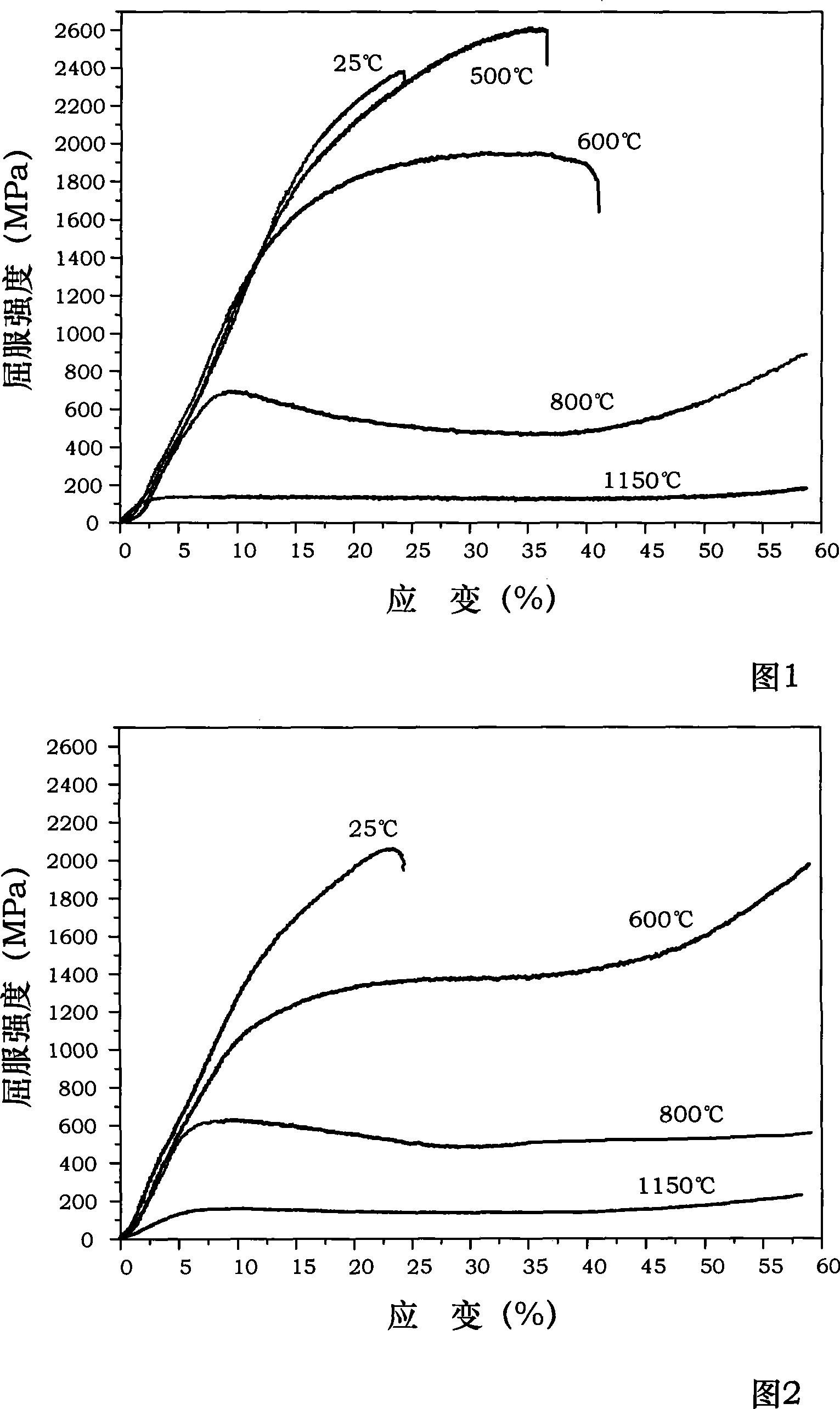

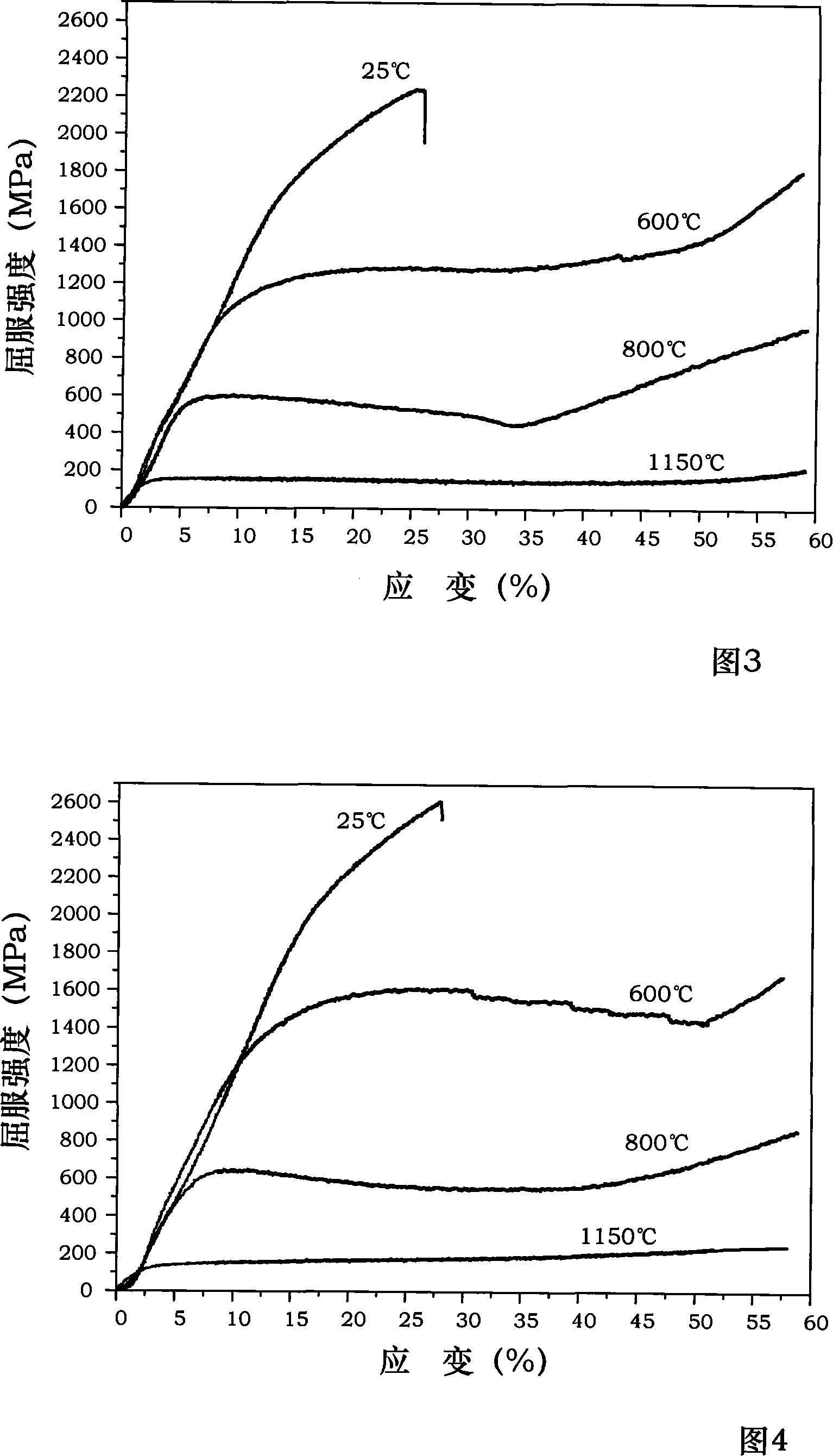

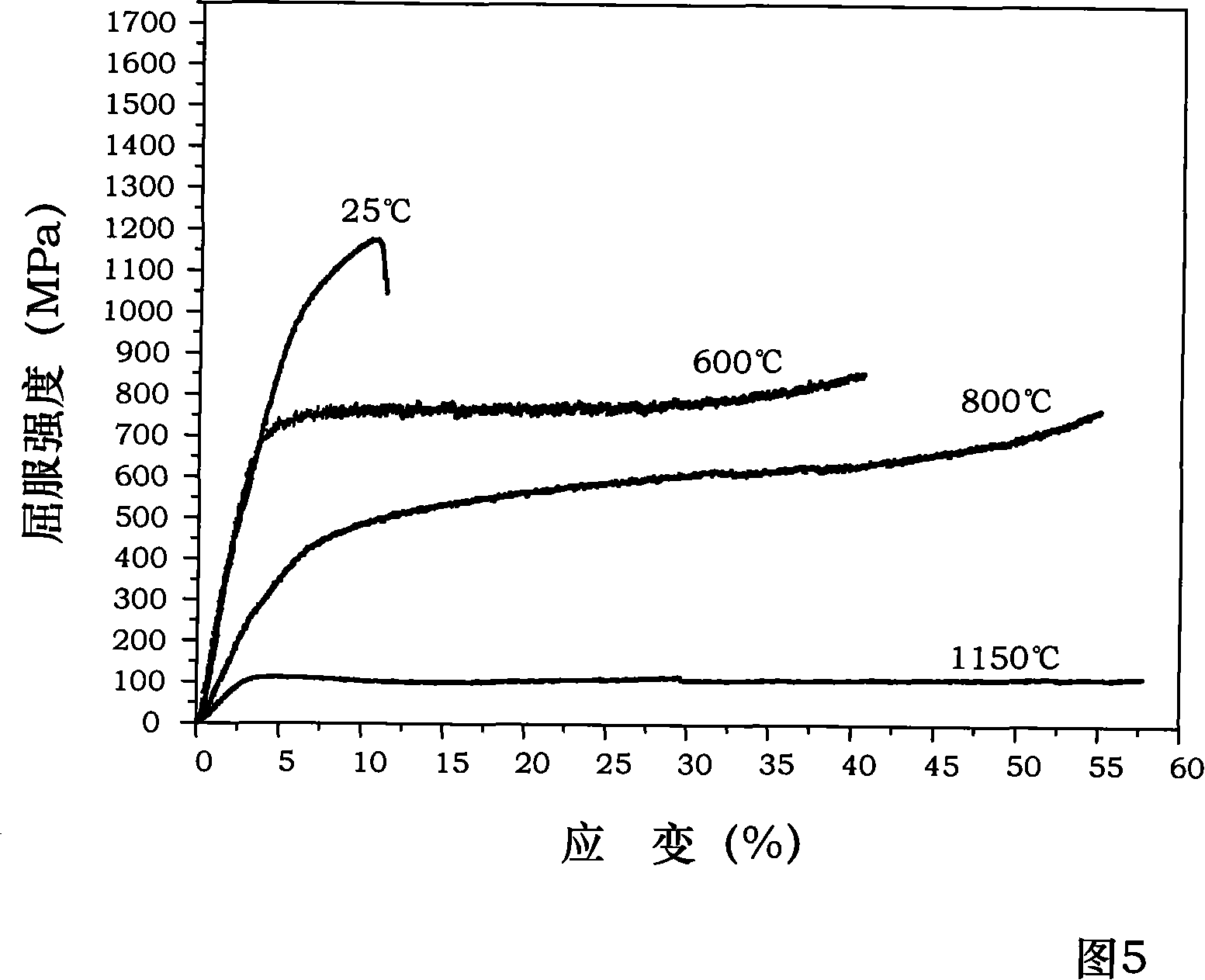

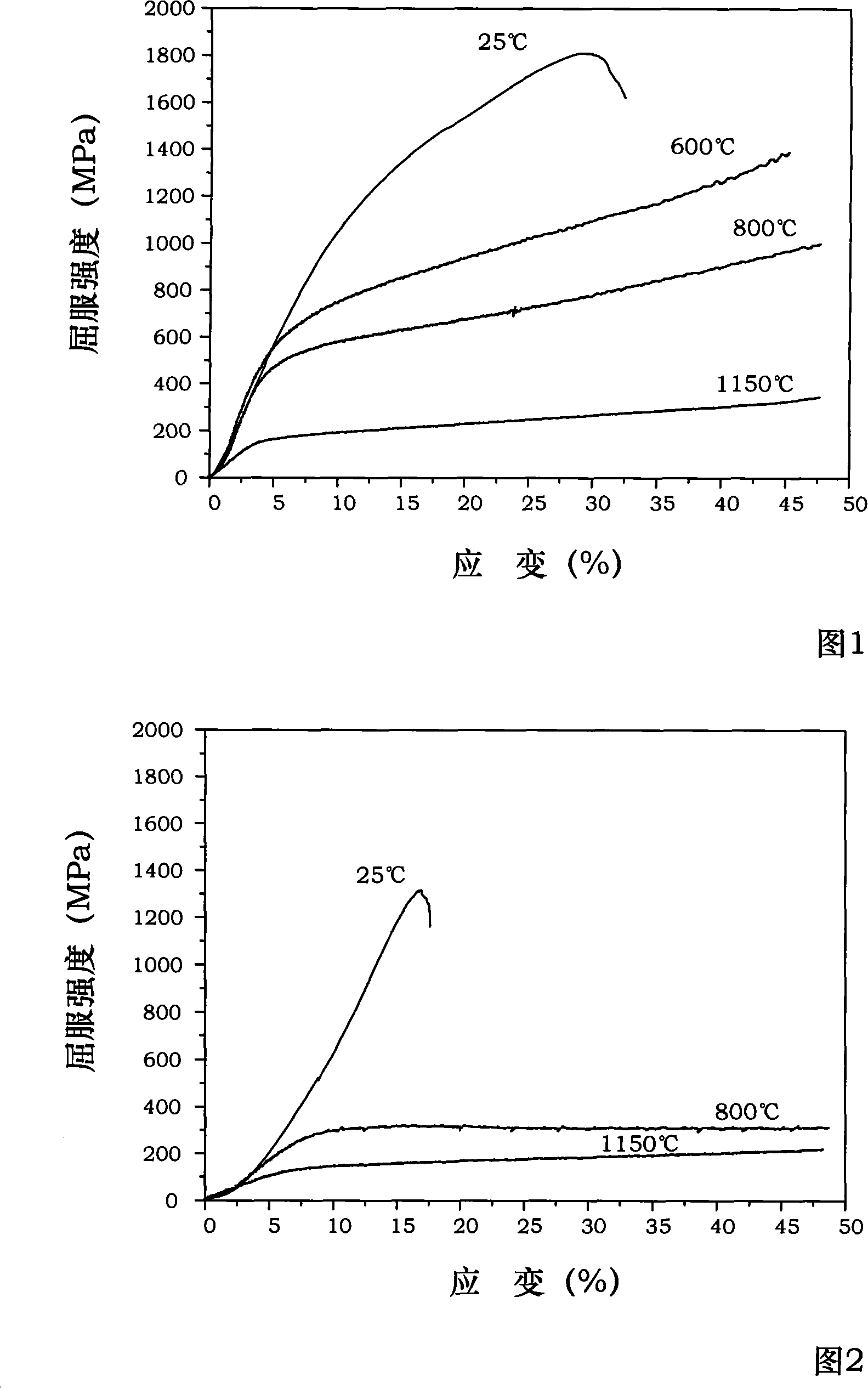

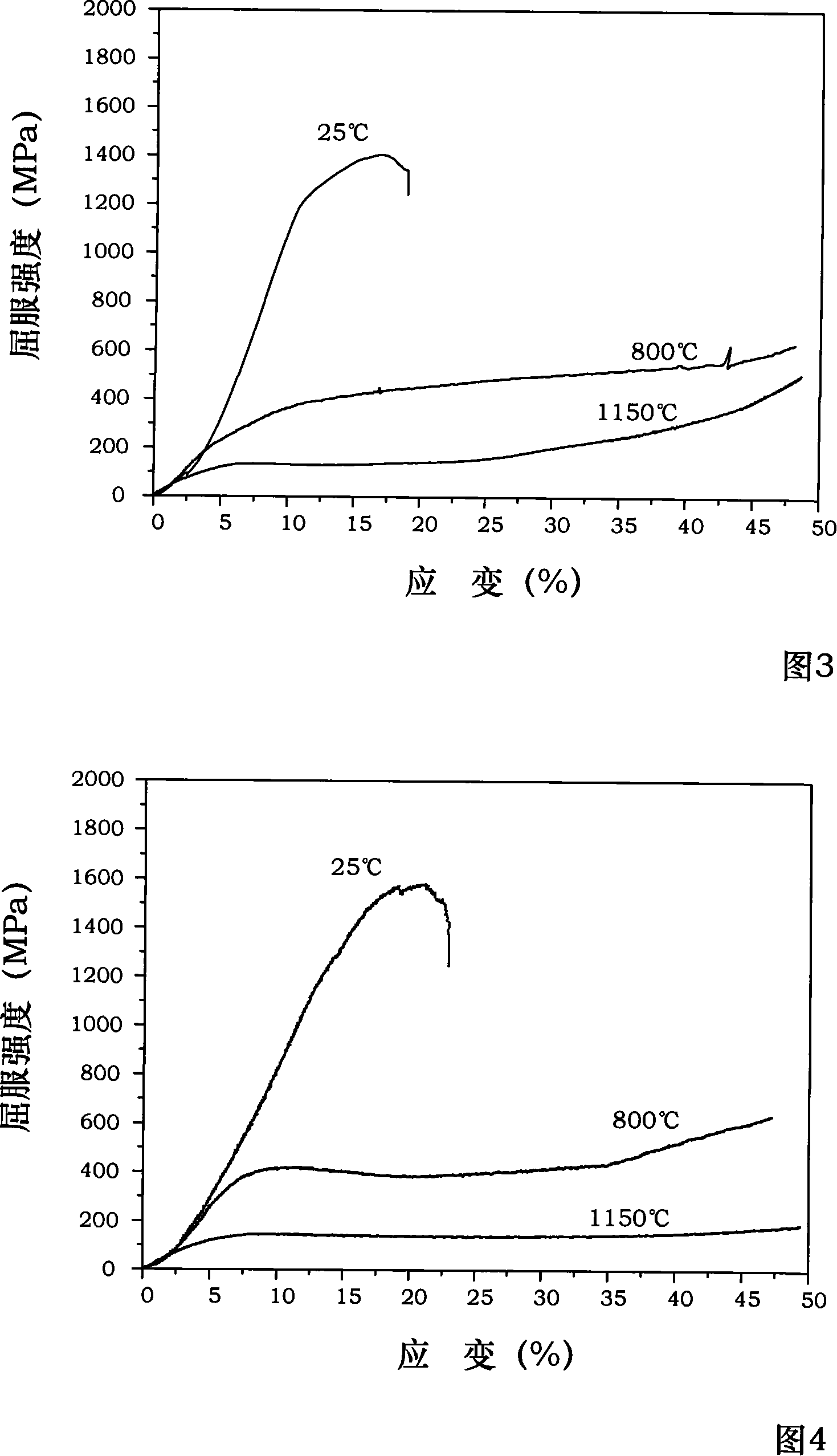

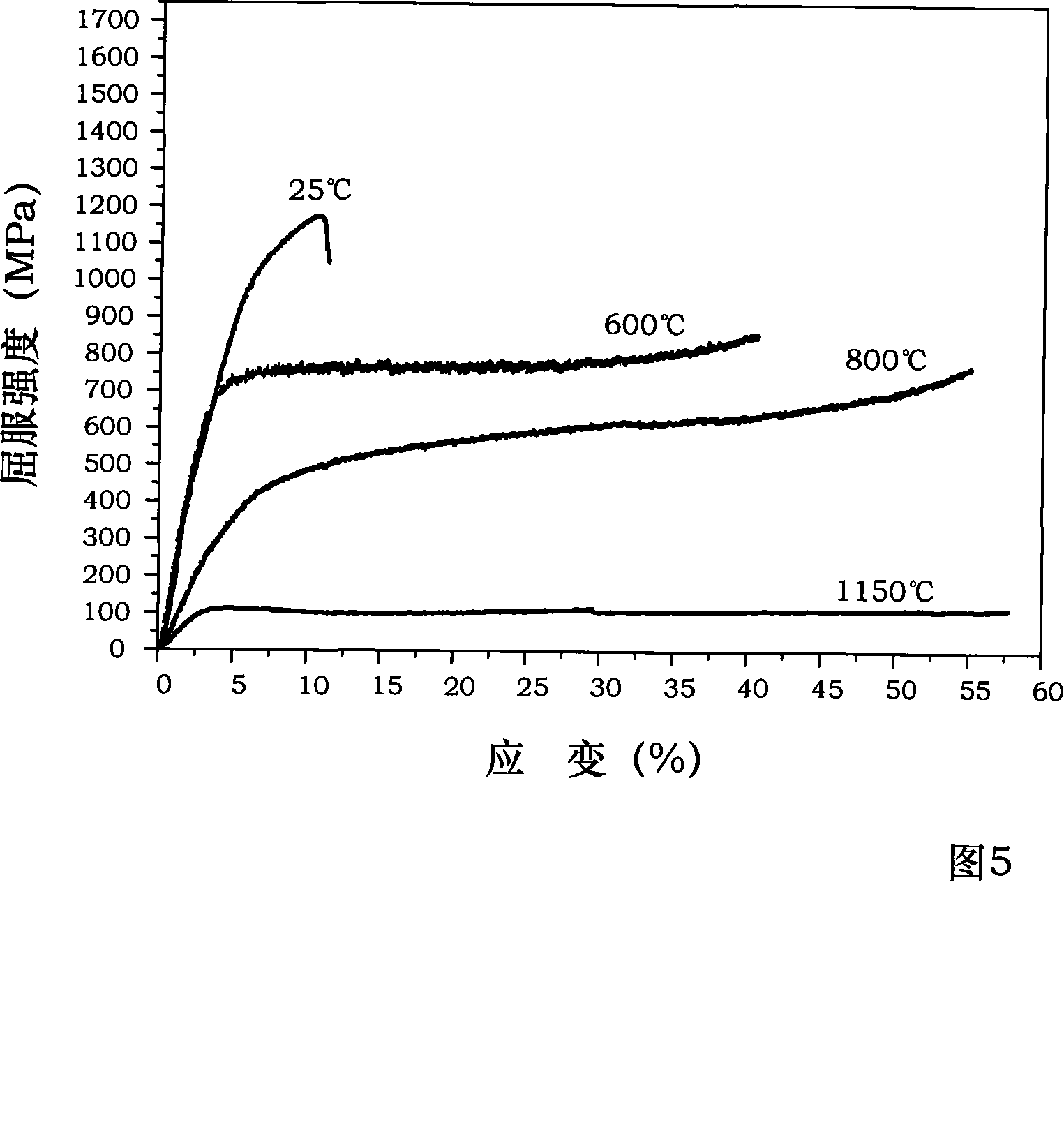

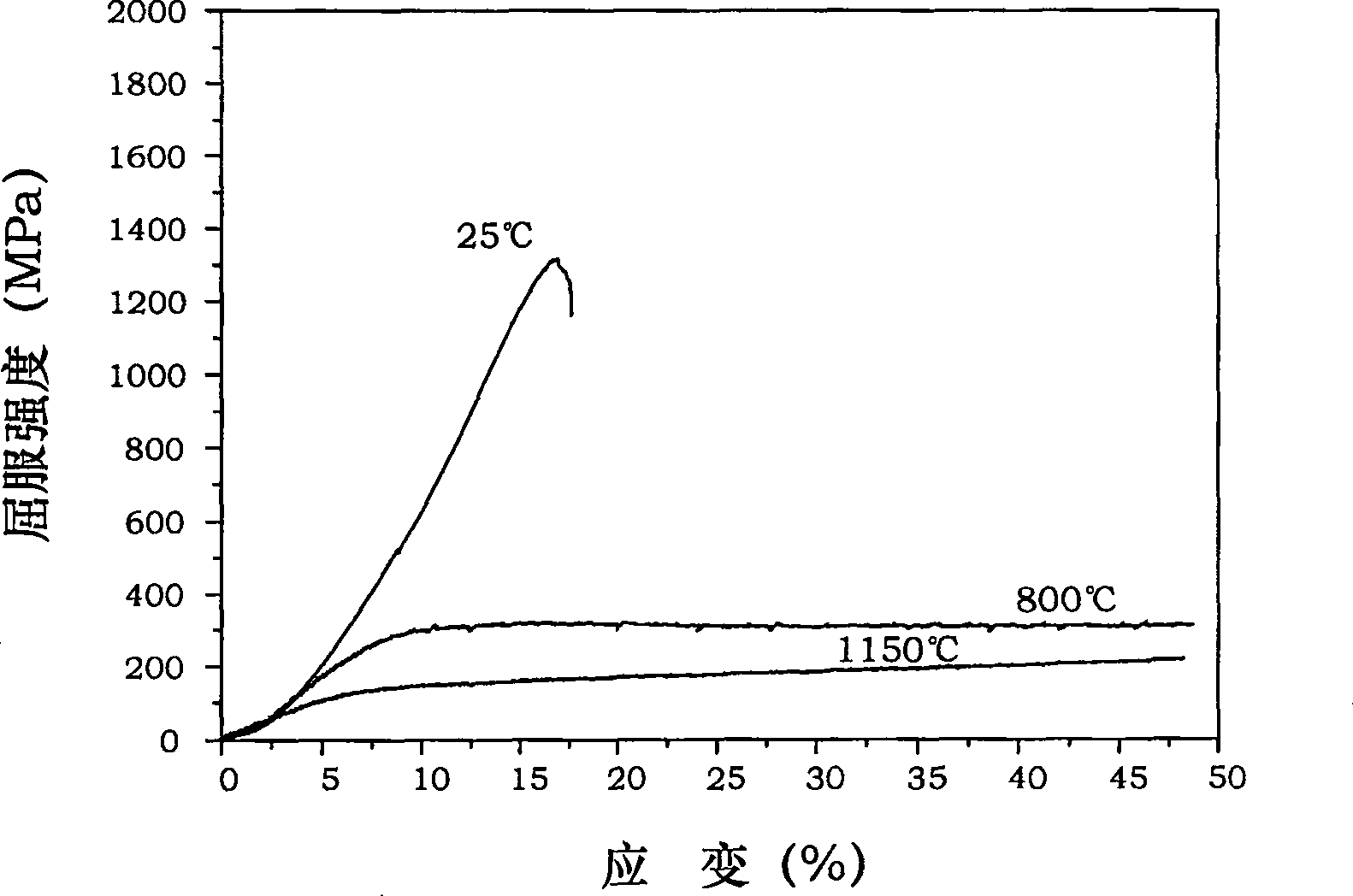

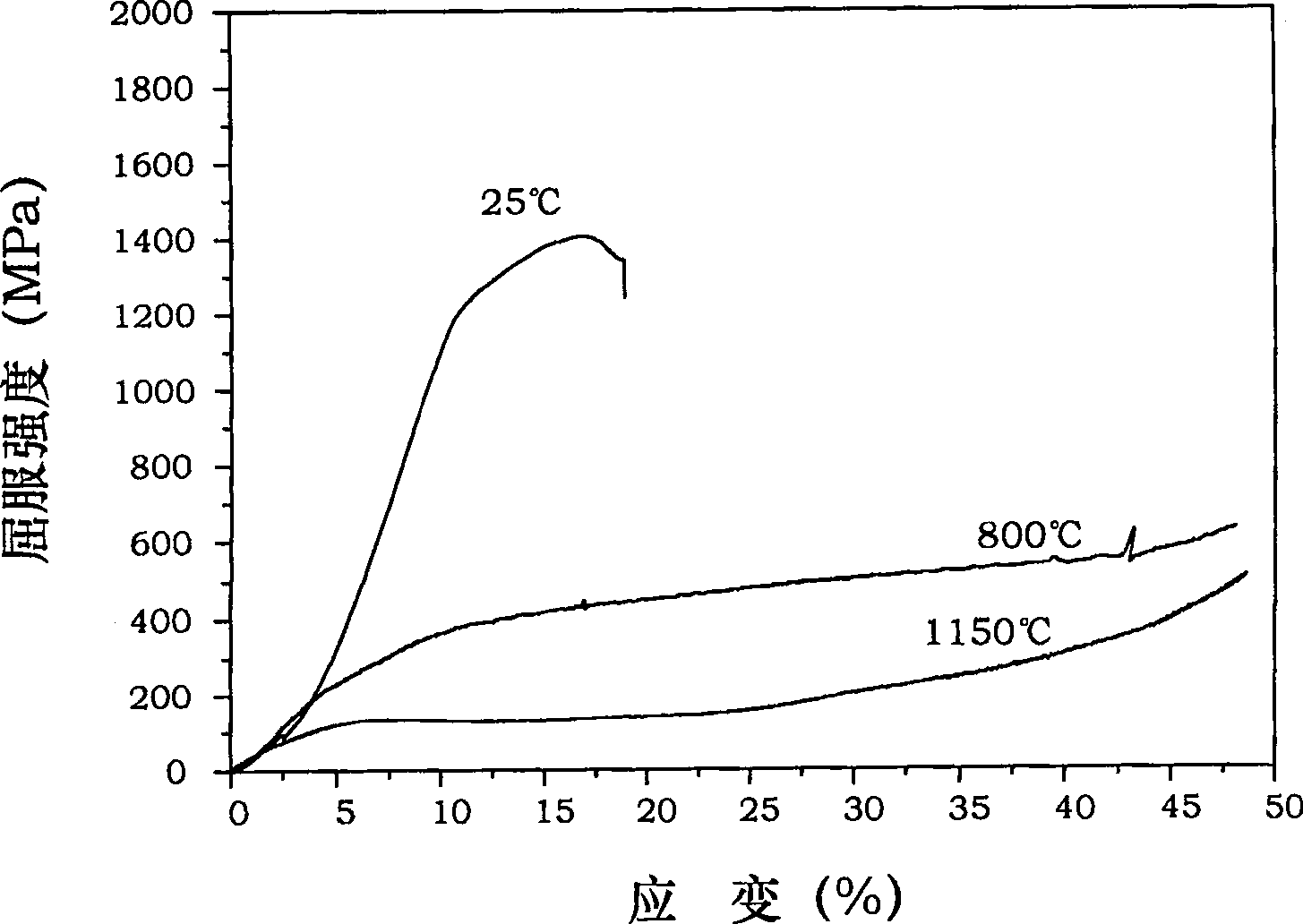

InactiveCN101148728AImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

The present invention discloses one kind of Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Ta in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Ta element to modify and form one Laves(Cr2Ta) phase with Cr, the Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 120-400 MPa and density of 6.1-6.9 g / cu cm.

Owner:BEIHANG UNIV

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Ta

InactiveCN100497700CImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

The present invention discloses one kind of Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Ta in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Ta element to modify and form one Laves(Cr2Ta) phase with Cr, the Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 120-400 MPa and density of 6.1-6.9 g / cu cm.

Owner:BEIHANG UNIV

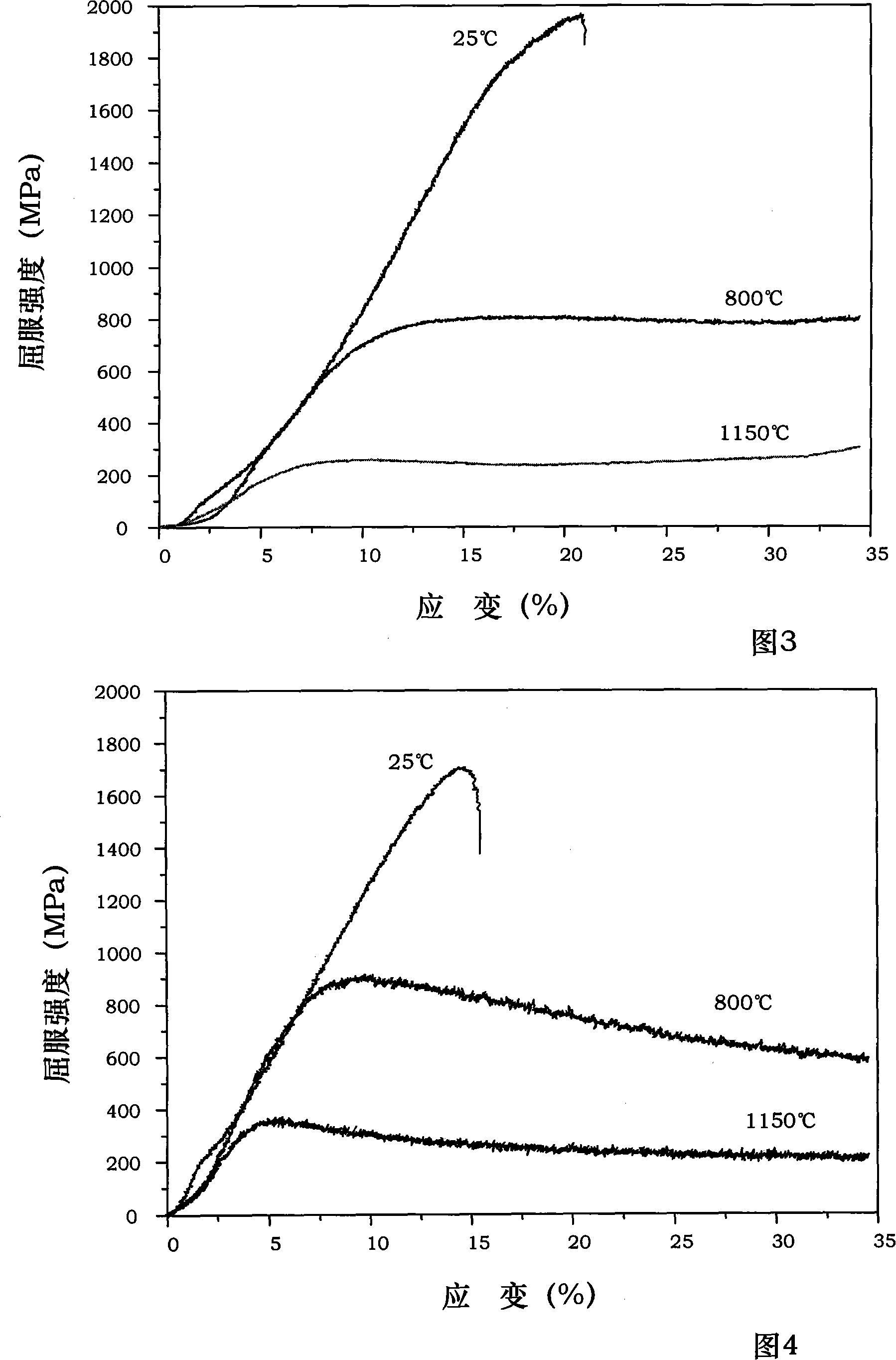

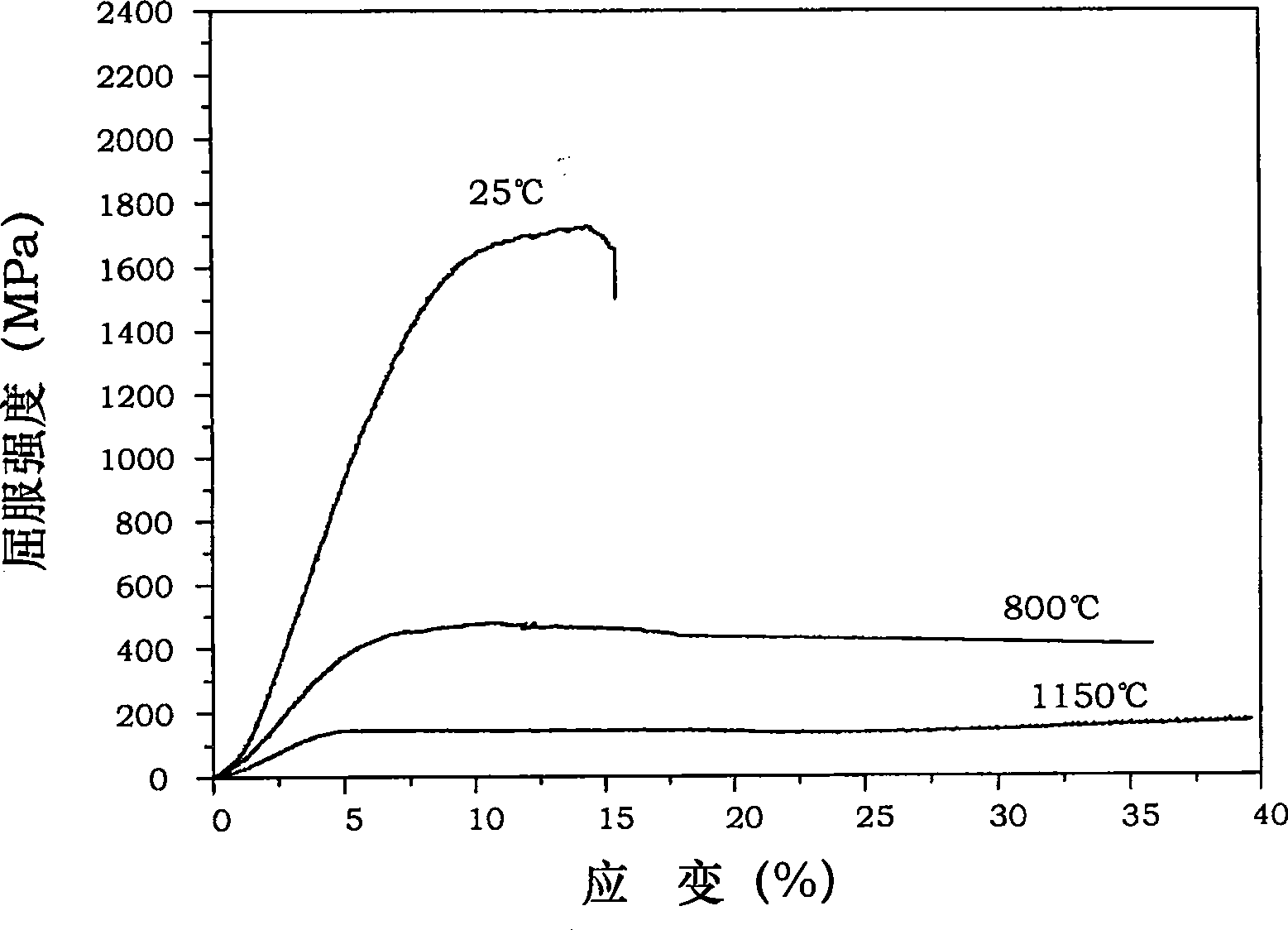

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by V

The present invention discloses one kind of V modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, V in 1-16 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding V element to modify and form one Heusler phase to reinforce the base and raise the high temperature performance, the V modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The V modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 120-150 MPa and density of 6.0-6.6 g / cu cm.

Owner:BEIHANG UNIV

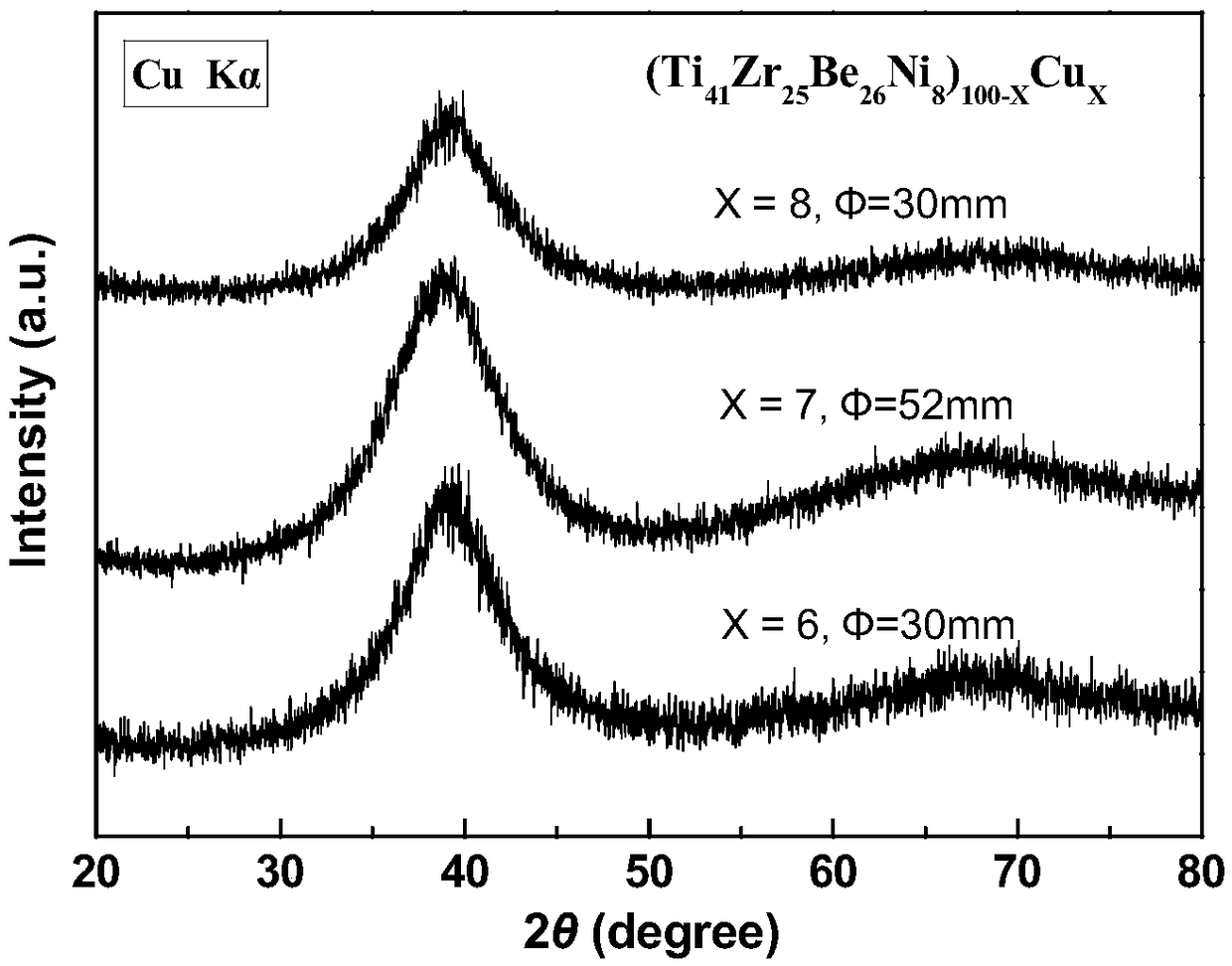

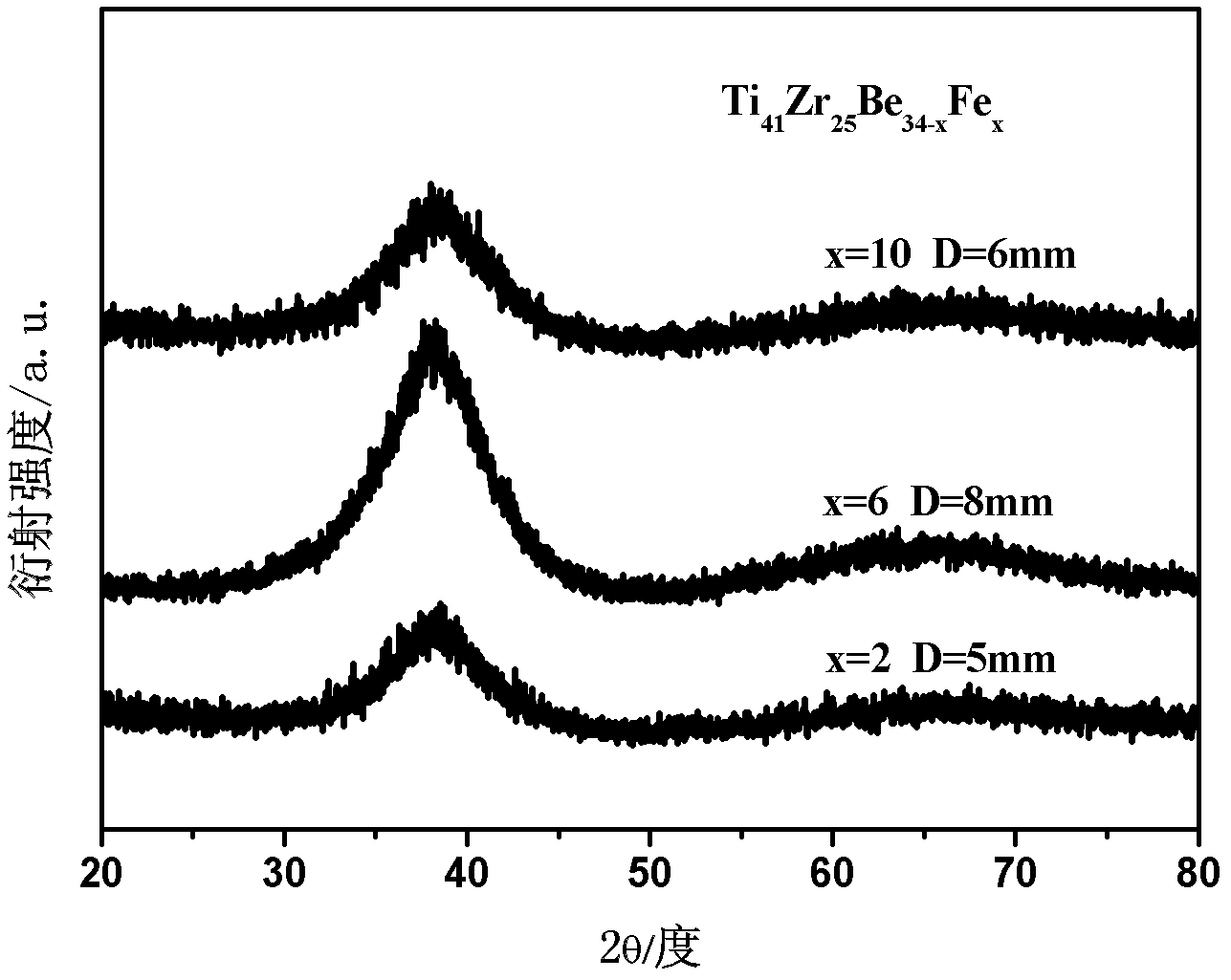

Ti-based amorphous alloy with super-large amorphous forming ability and preparation method thereof

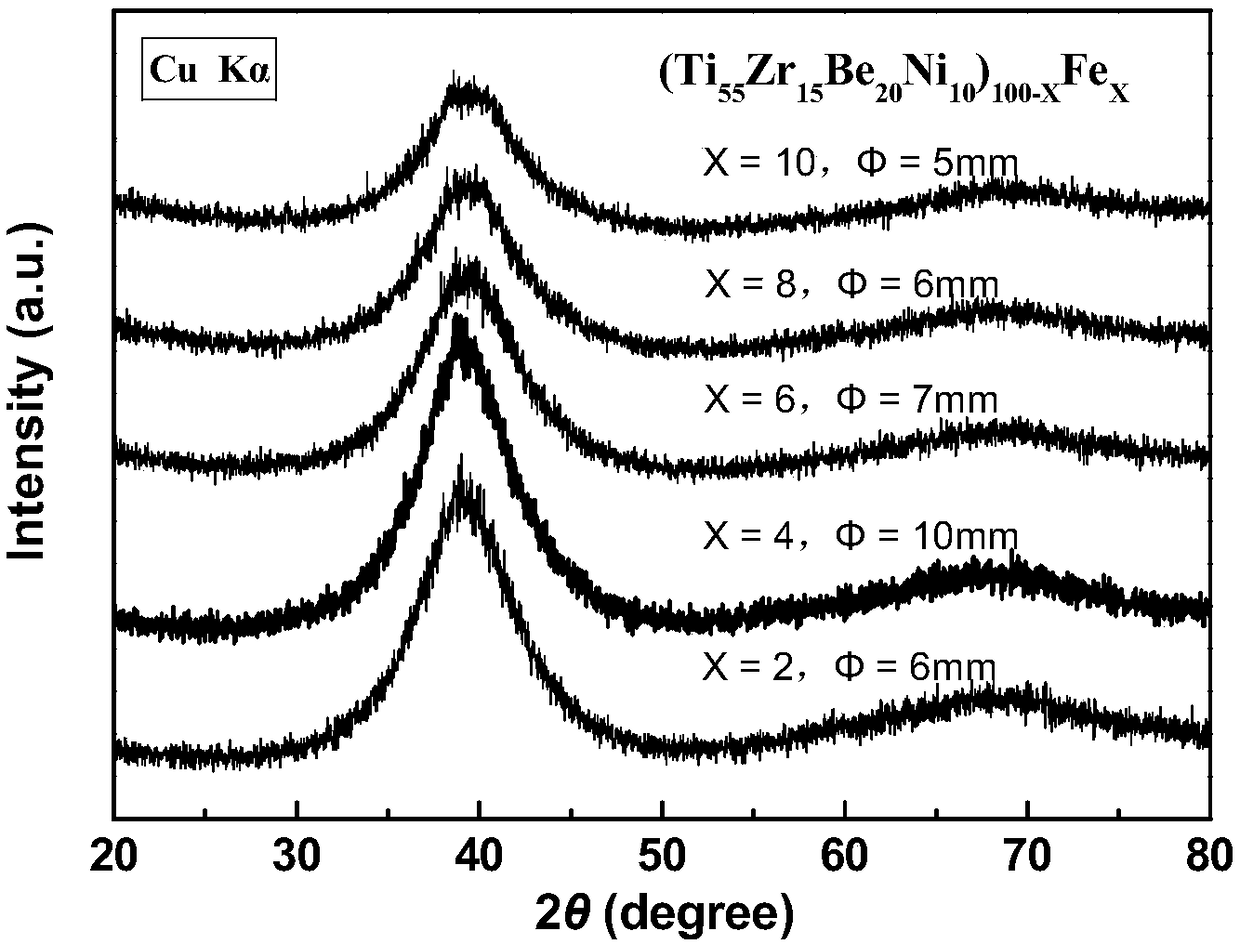

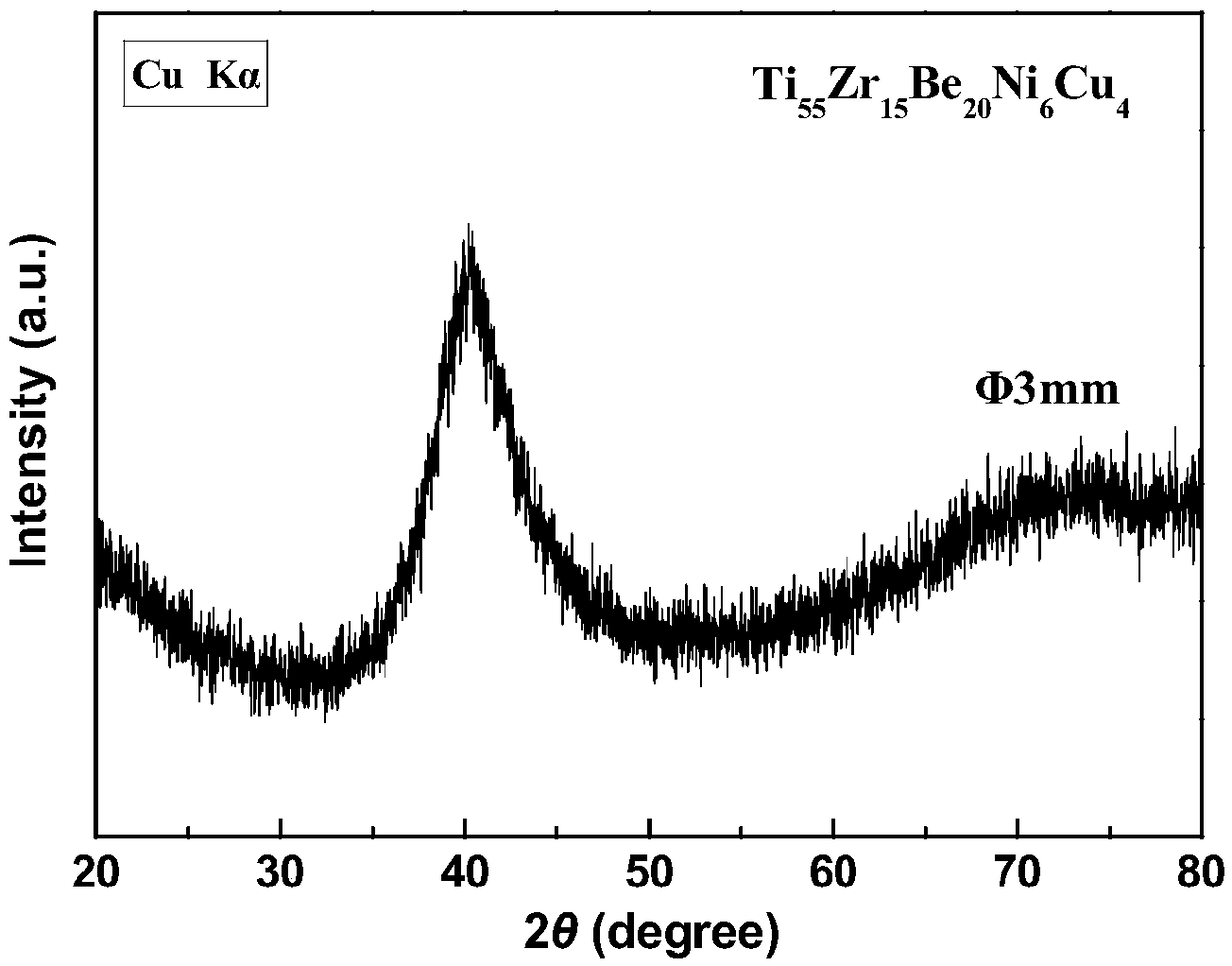

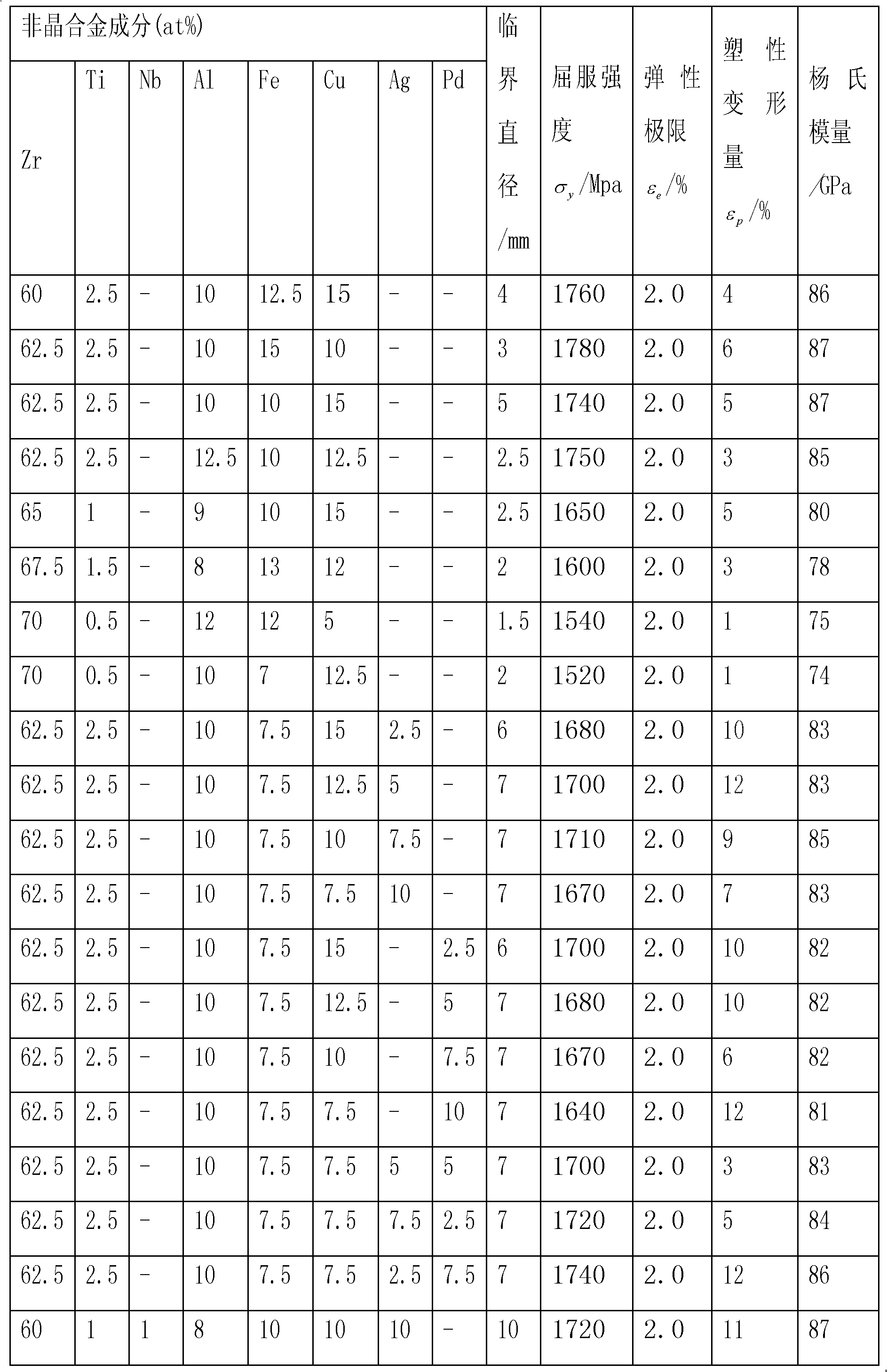

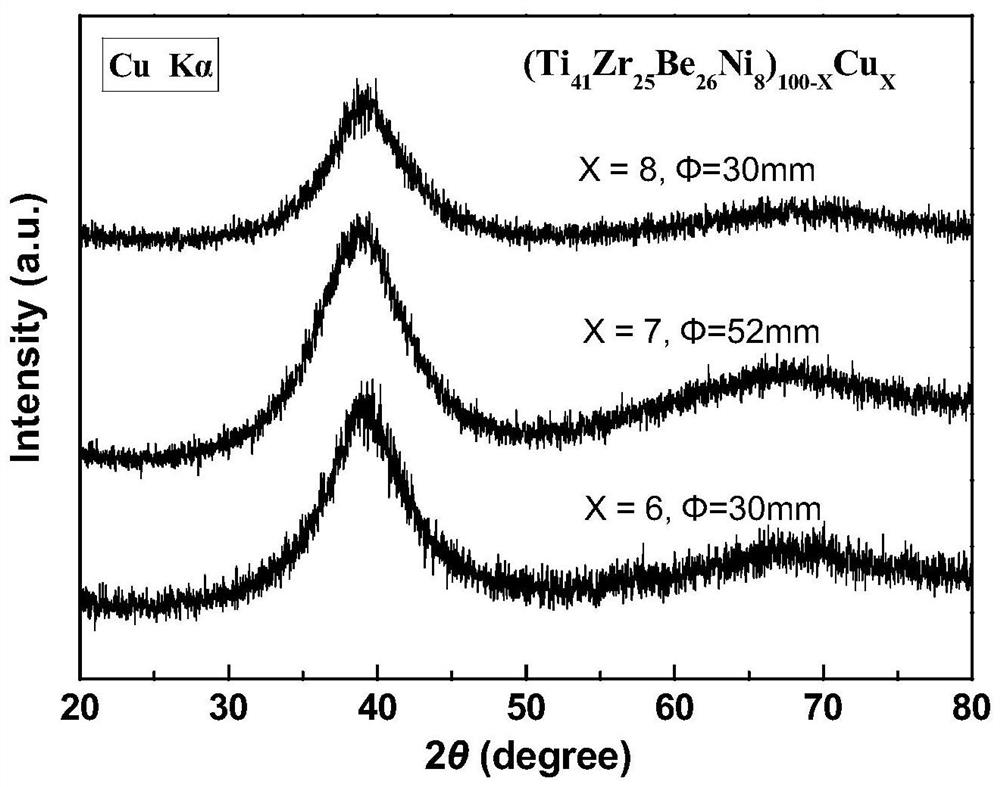

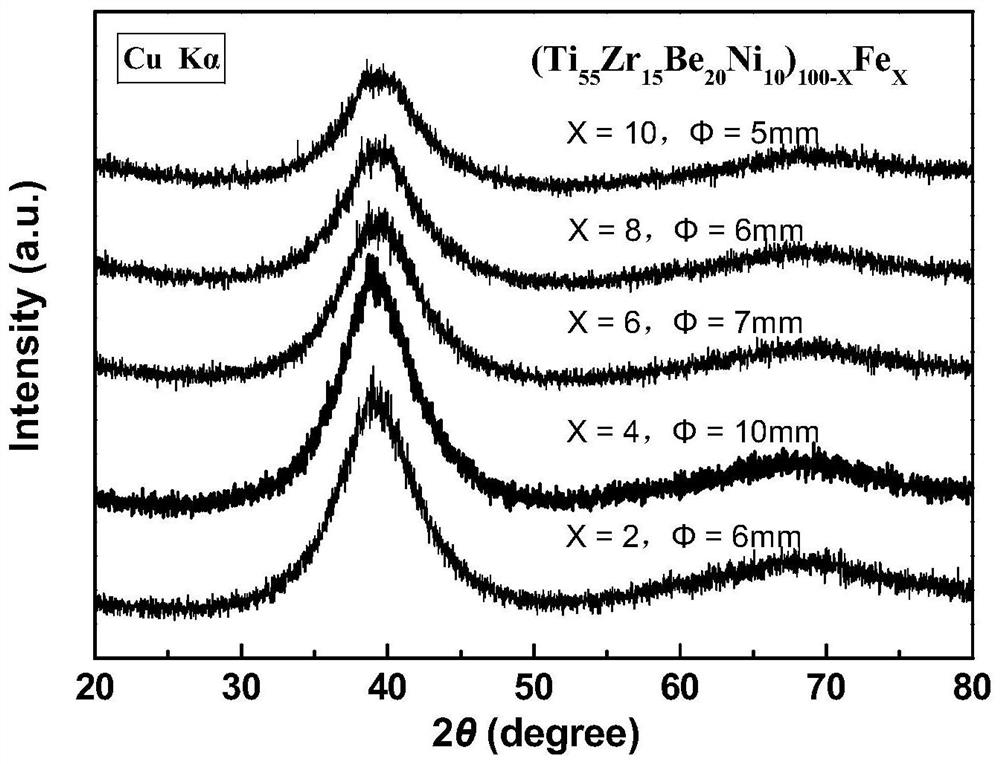

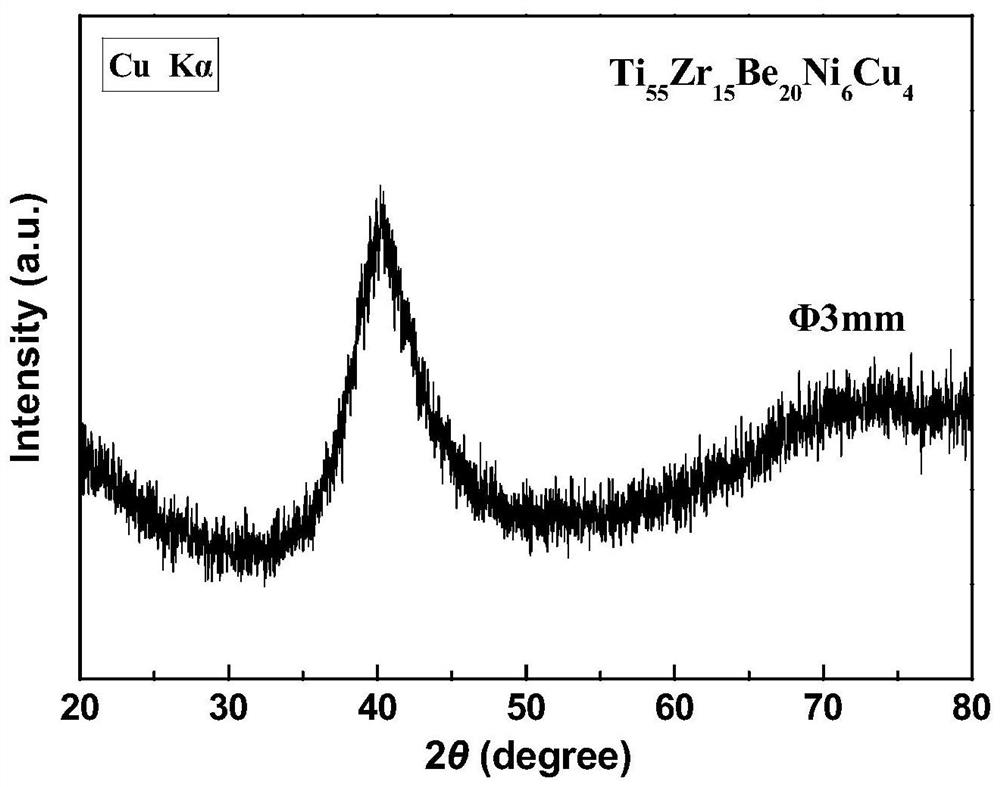

The invention belongs to the technical field of amorphous alloy materials, and relates to a Ti-Zr-Be-Ni-Cu (Fe) amorphous alloy with super-large amorphous forming ability and a preparation method thereof. The Ti-based amorphous alloy has the following composition represented by the following general formula: (TiaZrbBecNid)100-xCux or (TiaZrbBecNid)100-xFex, wherein a, b, c, d, and x are atomic percentages and have the value ranges: 41<=a<=55, 15<=b<=25, 20<=c<=26, 8<=d<=10, 0<x<=12, and the sum of the atomic proportions of all the elements is 100. The preparation method of the Ti-based amorphous alloy comprises the following steps: converting the atomic percentages of the alloy components into the mass percentages, and weighing with highly pure raw materials; pumping an electric arc melting chamber to high vacuum, and preparing an alloy ingot by electric arc melting under argon protection; and melting the obtained alloy ingot, carrying out suction casting, spray casting or pour castingto prepare the amorphous alloy with required shape and size. The maximum critical size of the prepared Ti-based amorphous alloy can reach 52 mm, and the Ti-based amorphous alloy is expected to be applied in the fields of aerospace and aviation.

Owner:TSINGHUA UNIV

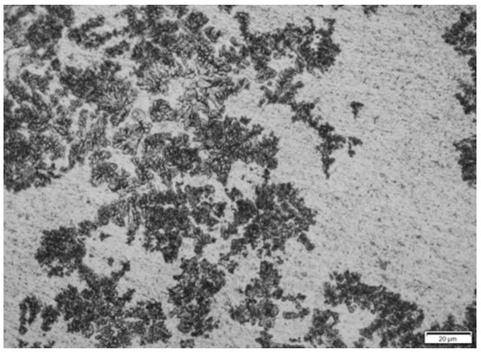

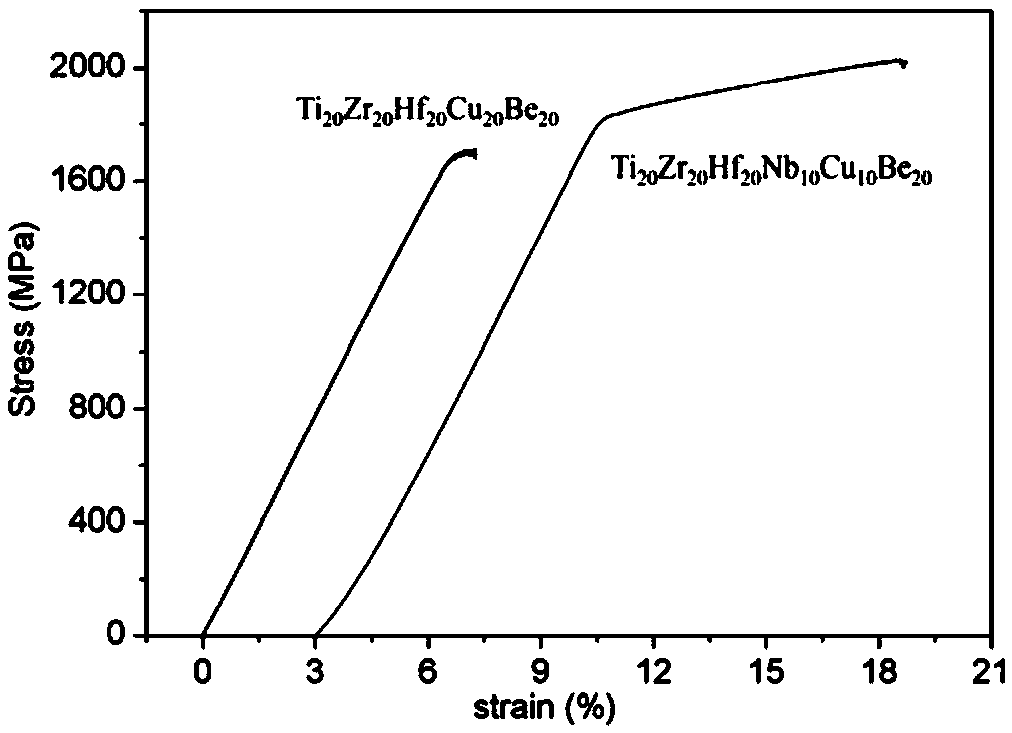

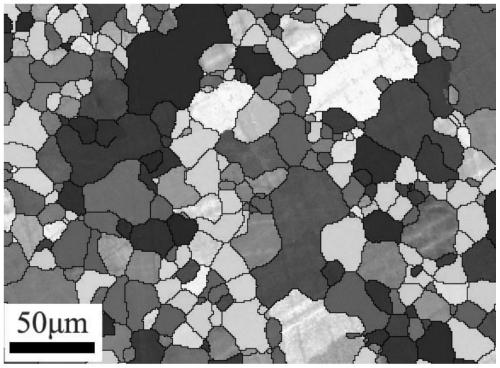

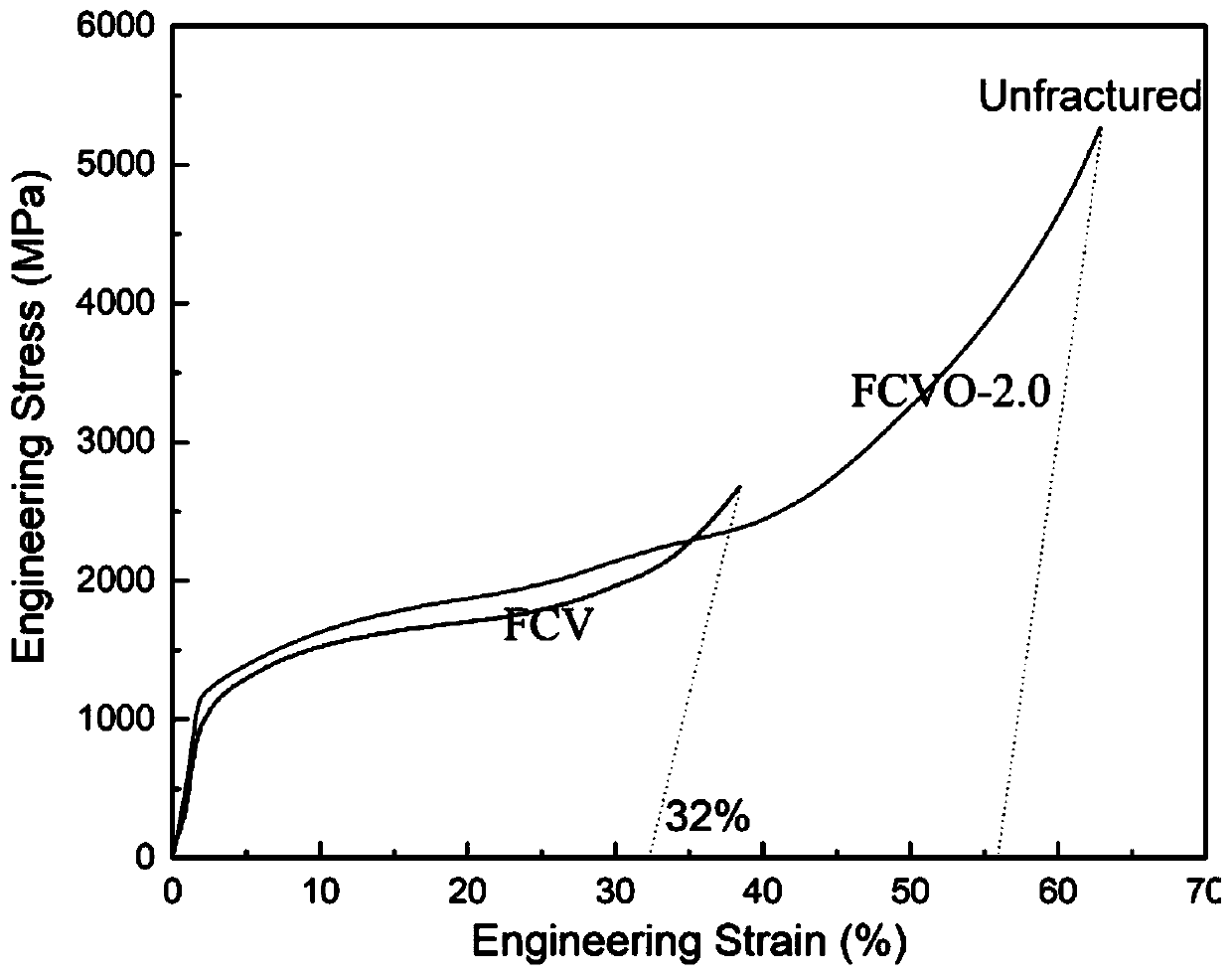

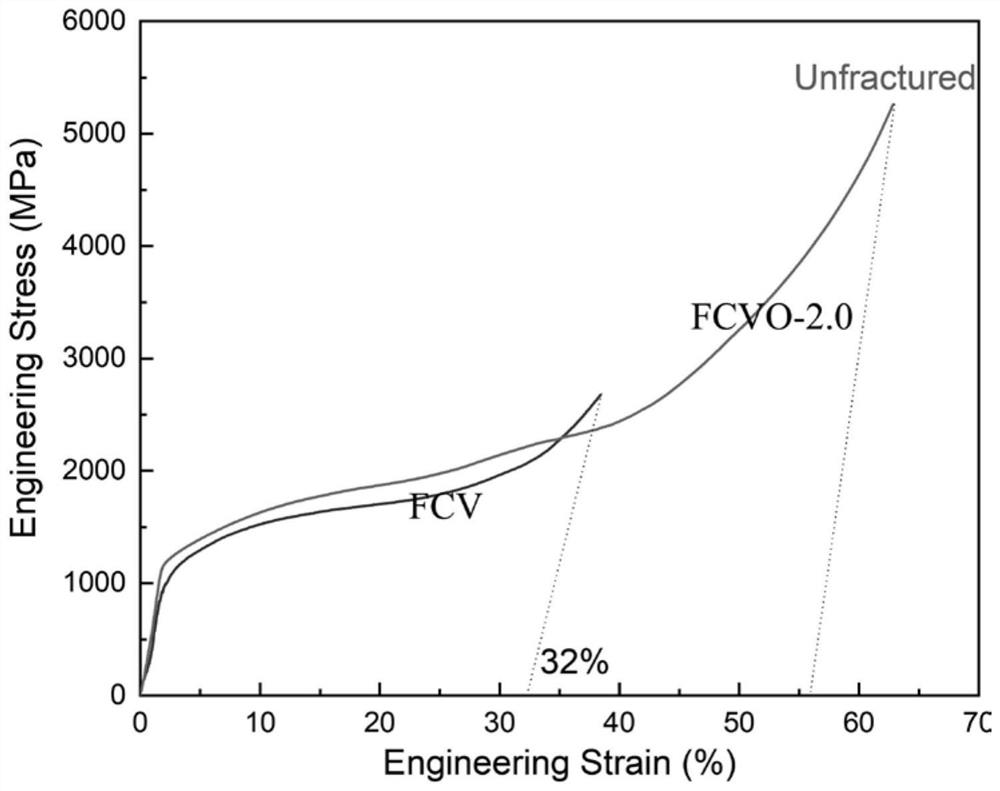

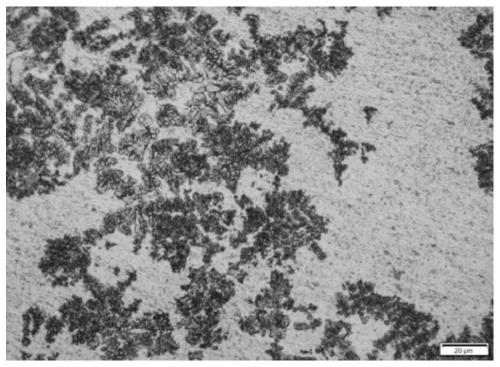

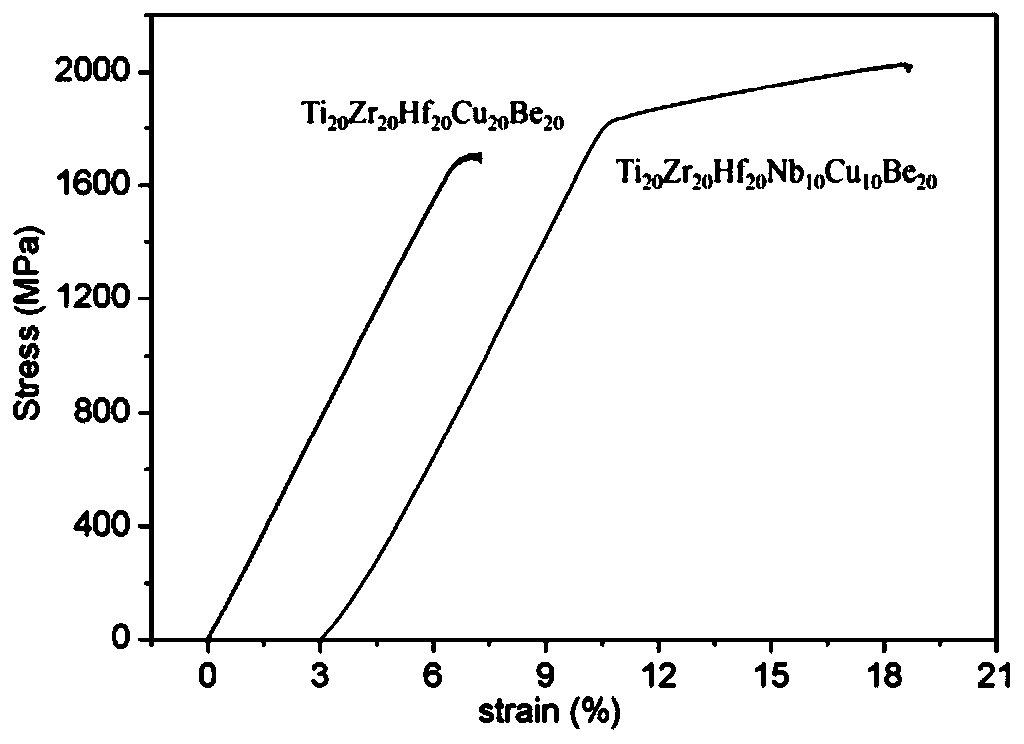

Preparation method of Ti-based high-entropy amorphous-dendritic composite material

The invention provides a preparation method of a Ti-based high-entropy amorphous-dendritic composite material. The preparation method is mainly characterized in that Ti20Zr20Hf20Nb10Cu10Be20 of a predesigned alloy proportion is alloyed through a vacuum electric-arc furnace, and comprises the following steps that elementary substance elements with the purity being larger than or equal to 99.9% areweighed according to the atom proportion of Ti25Zr25Hf25Nb25, smelting is carried out, and thus a first intermediate alloy is obtained; then elementary substance elements are weighed according to theatom proportion of Ti16.67Zr16.67Hf16.67Cu16.67Be16.67, smelting is carried out, and thus a second intermediate alloy is obtained; and finally the first intermediate alloy and the second intermediatealloy are subjected to mixed smelting and suction-casting, and thus the high-entropy amorphous-dendritic composite material Ti20Zr20Hf20Nb10Cu10Be20 is obtained. The preparation method provided by theinvention is simple and easy to operate, the compression performance of the obtained composite material is significantly improved, and the method is suitable for industrial production and popularization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Zr

The present invention discloses one kind of Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Zr in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Zr element to modify and form one Heusler(L21-Ni2AlZr) phase with NiAl, the Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 110-130 MPa and density of 6.1-6.7 g / cu cm.

Owner:BEIHANG UNIV

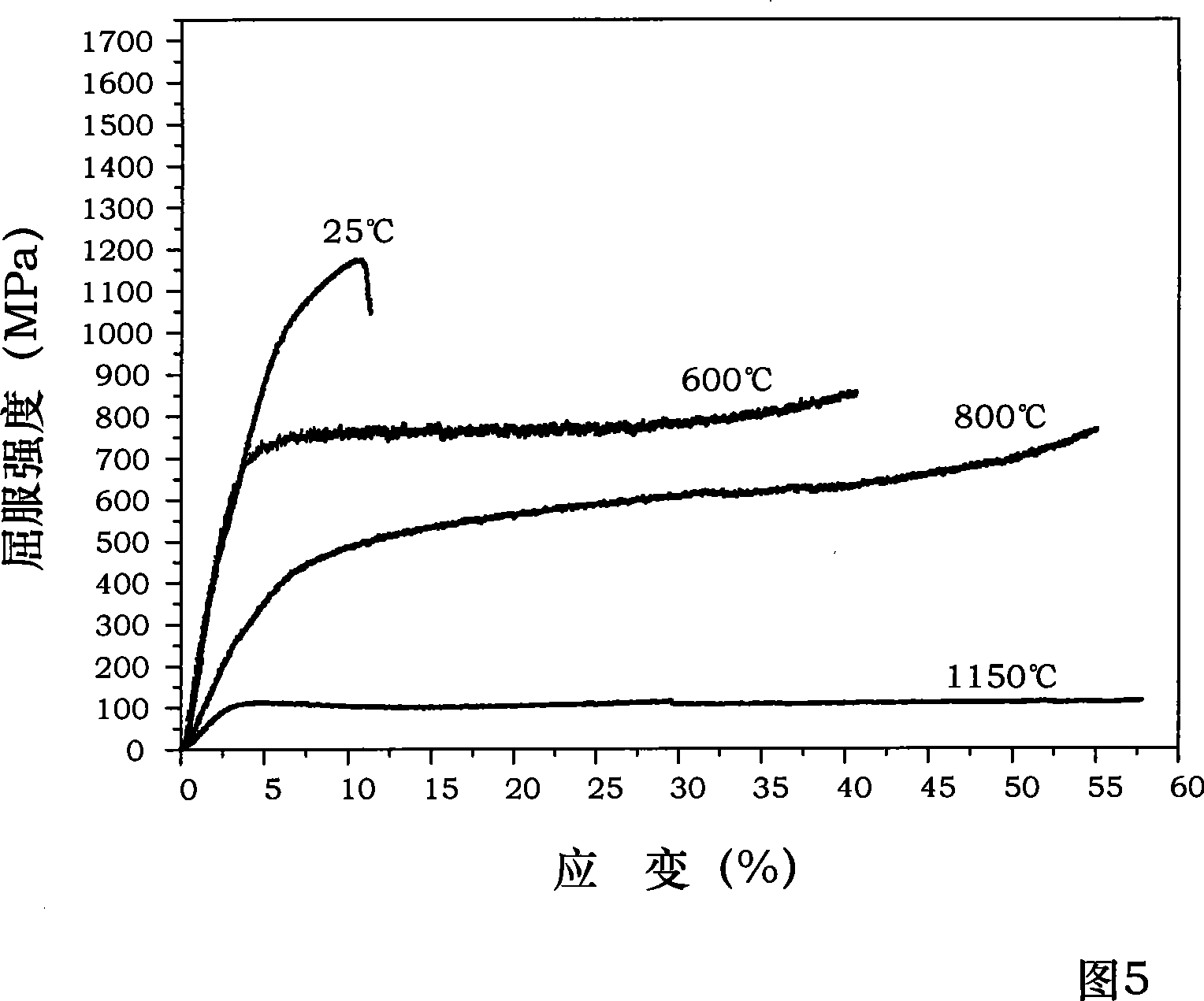

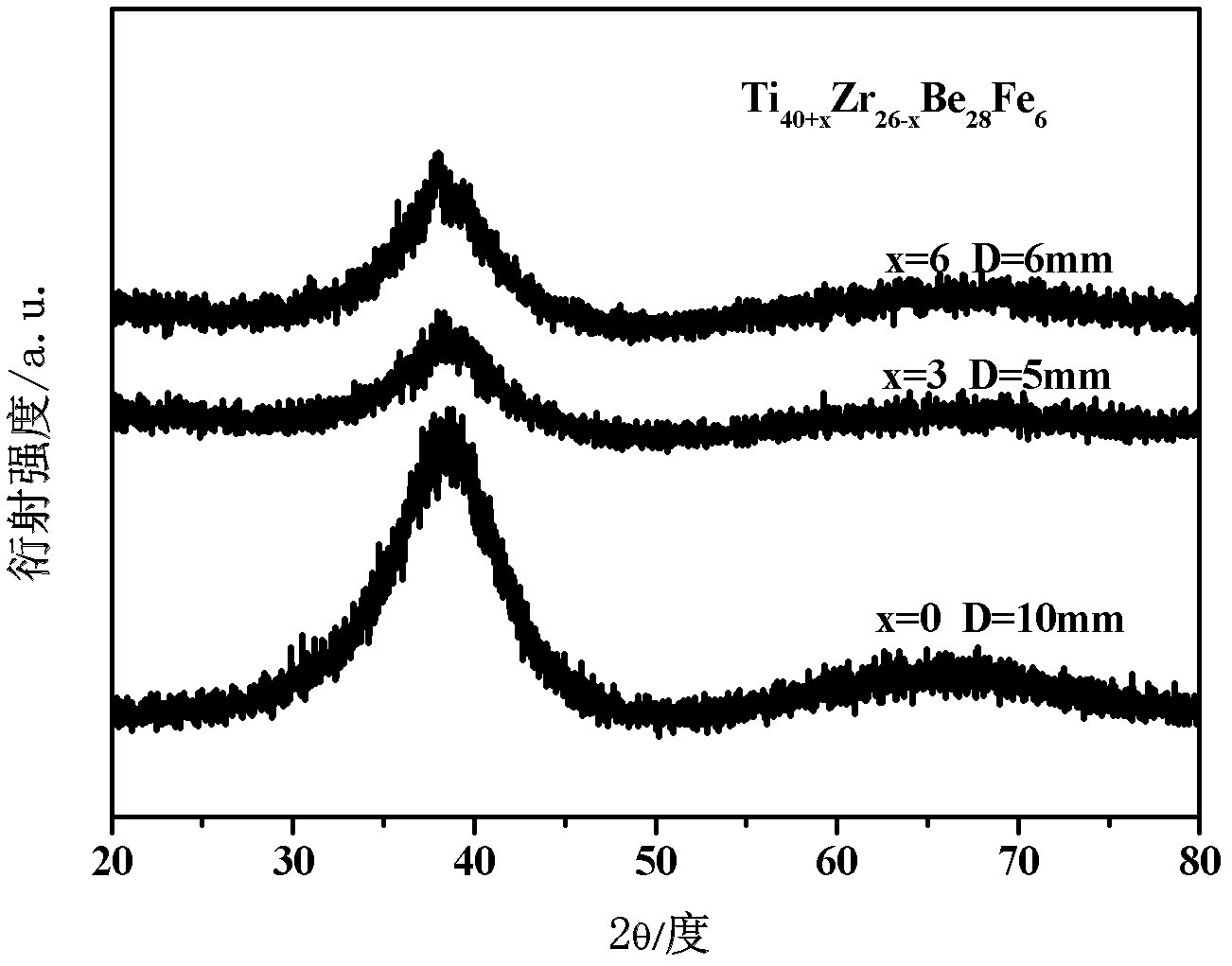

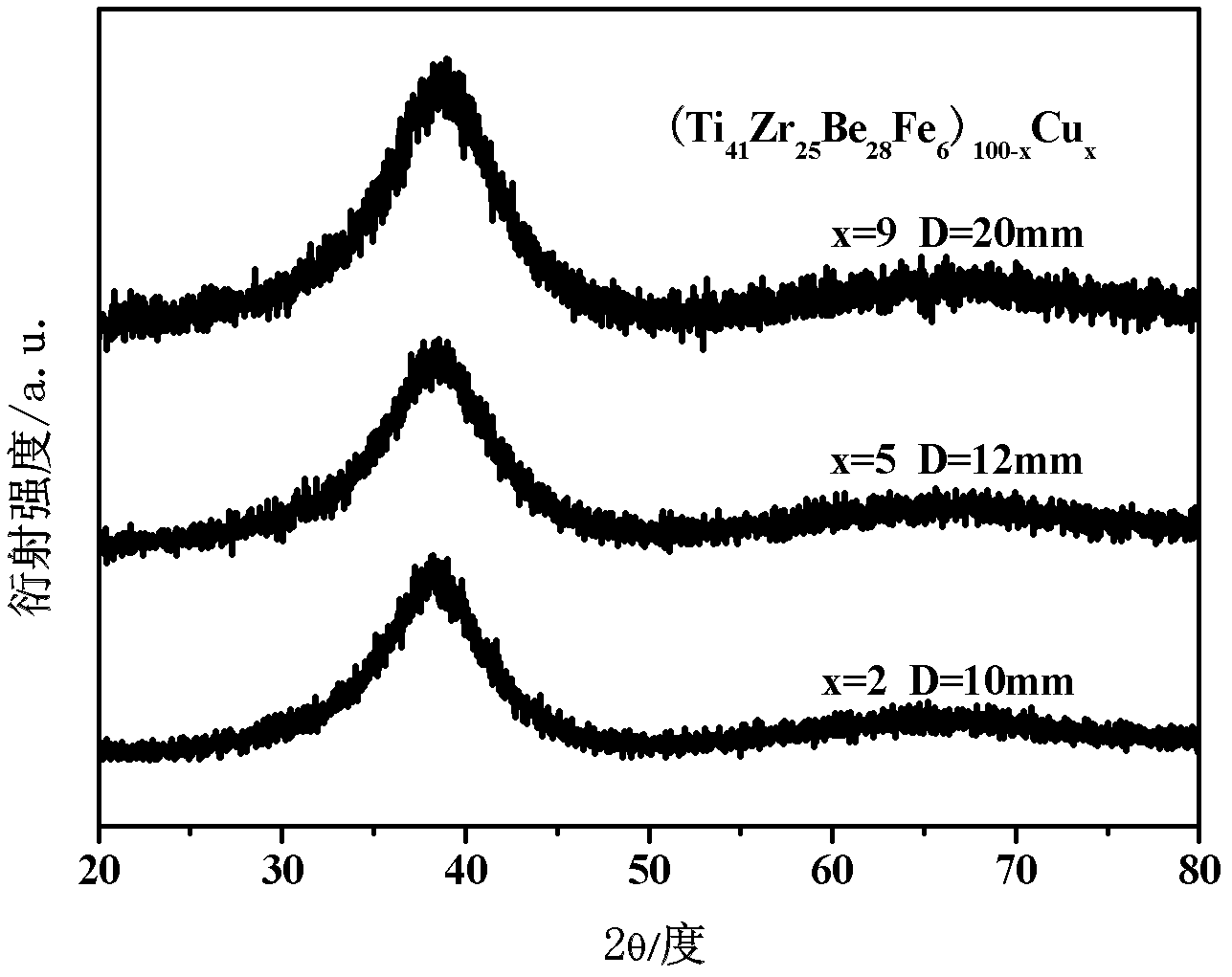

Ti-based block amorphous alloy with great amorphous forming ability and preparation method thereof

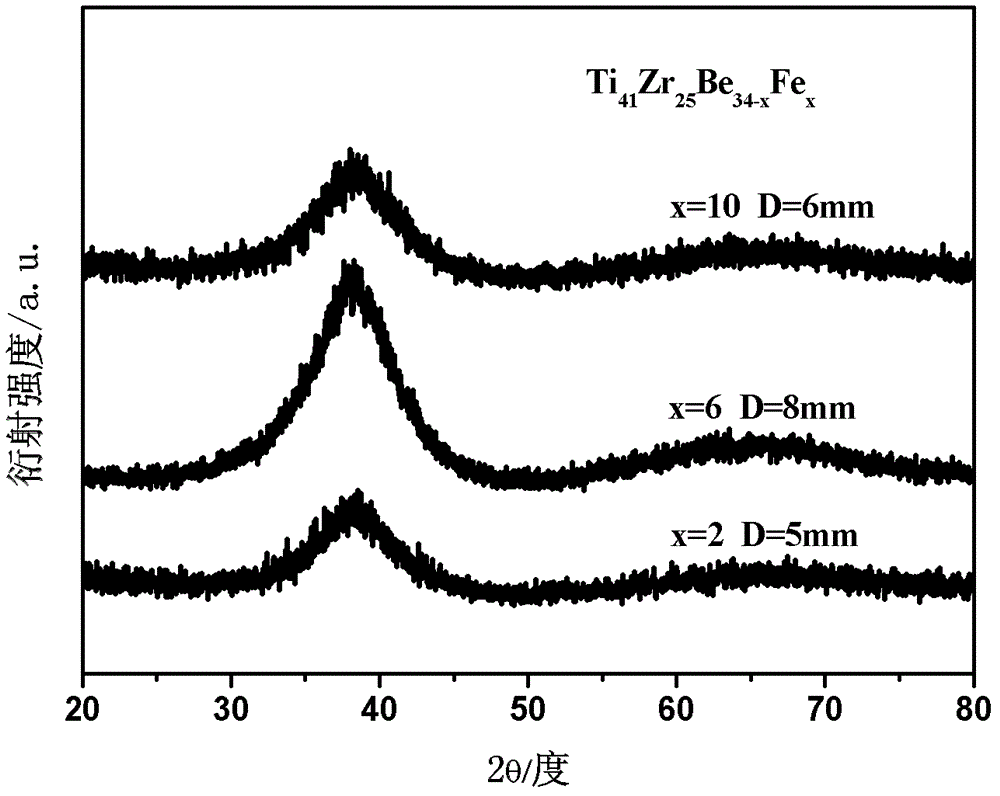

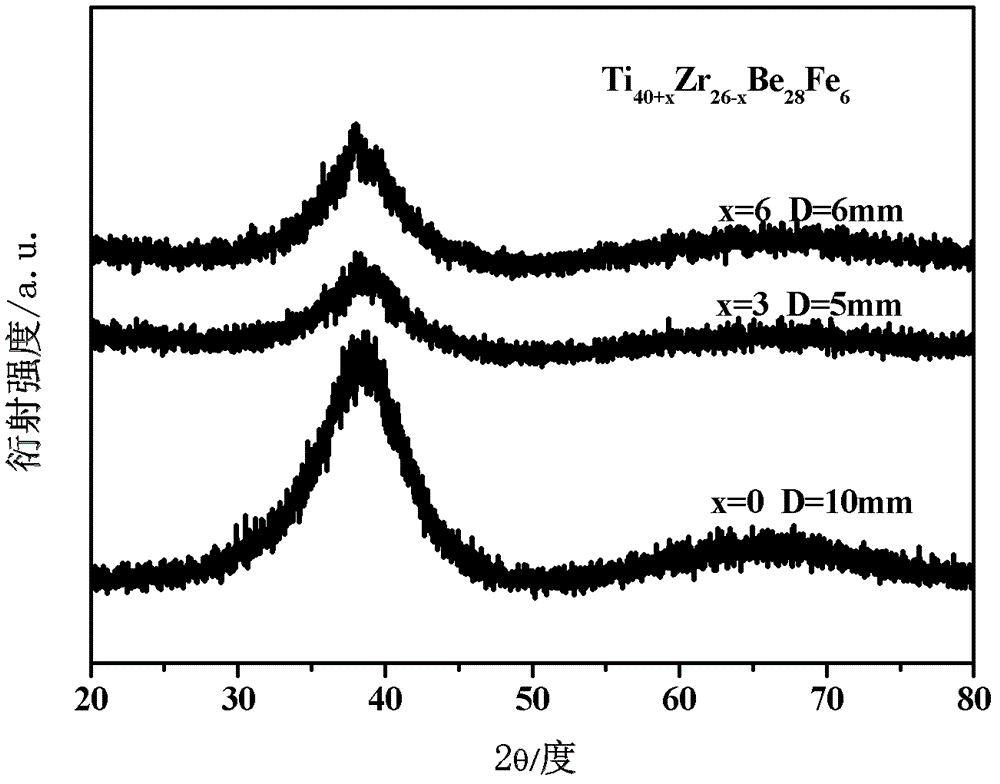

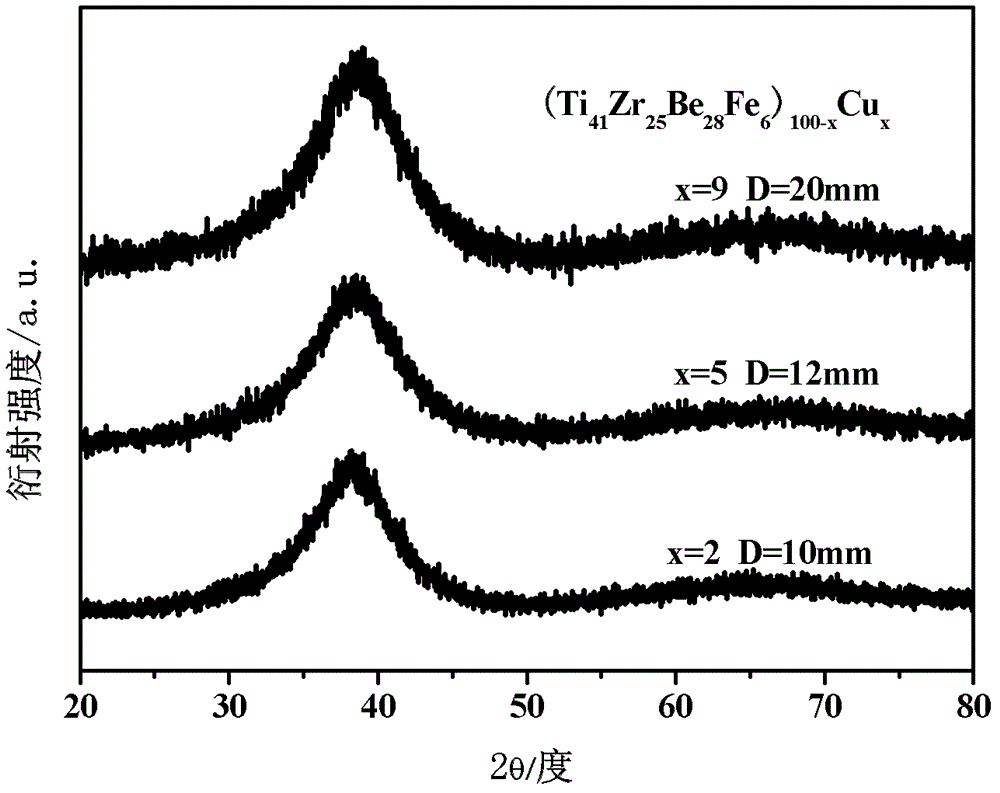

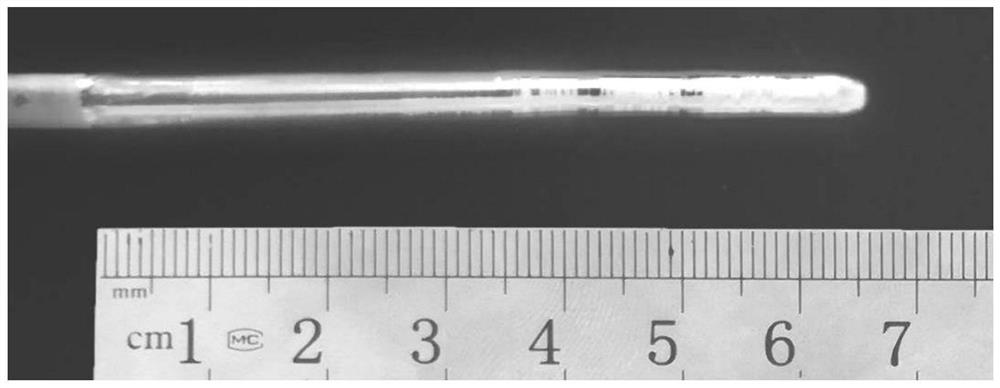

The invention discloses a Ti-based block amorphous alloy with a great amorphous forming ability and a preparation method thereof. The composition of the Ti-based block amorphous alloy is shown as the following general formula: (Ti66-xZrxBe34-yFey)100-zCuz, wherein, x, y and z are atomic percentage (*100), and have the value ranges that: x is greater than or equal to 20 and smaller than or equal to 26, y is greater than 0 and smaller than or equal to 12, and z is greater than or equal to 0 and smaller than or equal to 12. The preparation method of the Ti-based block amorphous alloy consists ofthe steps of: converting the atomic percent of the components in the Ti-based block amorphous alloy into mass percent, and weighing out raw materials; mixing and melting the raw materials under vacuum or gas protection and making a master alloy ingot; melting the master alloy ingot which is then put into an oxygen-free copper die through suction casting or spray casting, thus obtaining the Ti-based block amorphous alloy. The preparation method of the invention can prepare Ti-based block amorphous alloys with a good amorphous forming ability and a low density at a low cost.

Owner:TSINGHUA UNIV

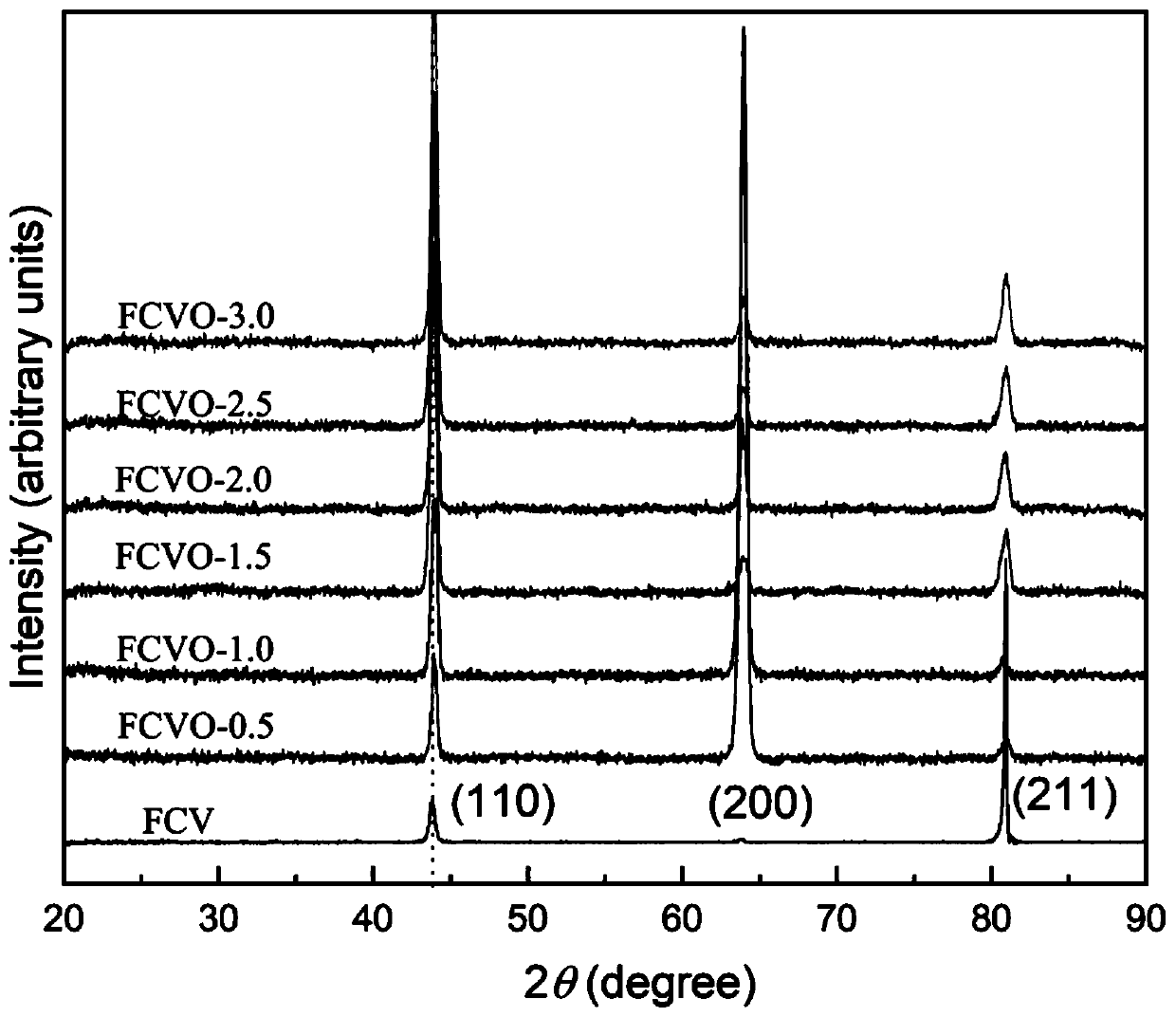

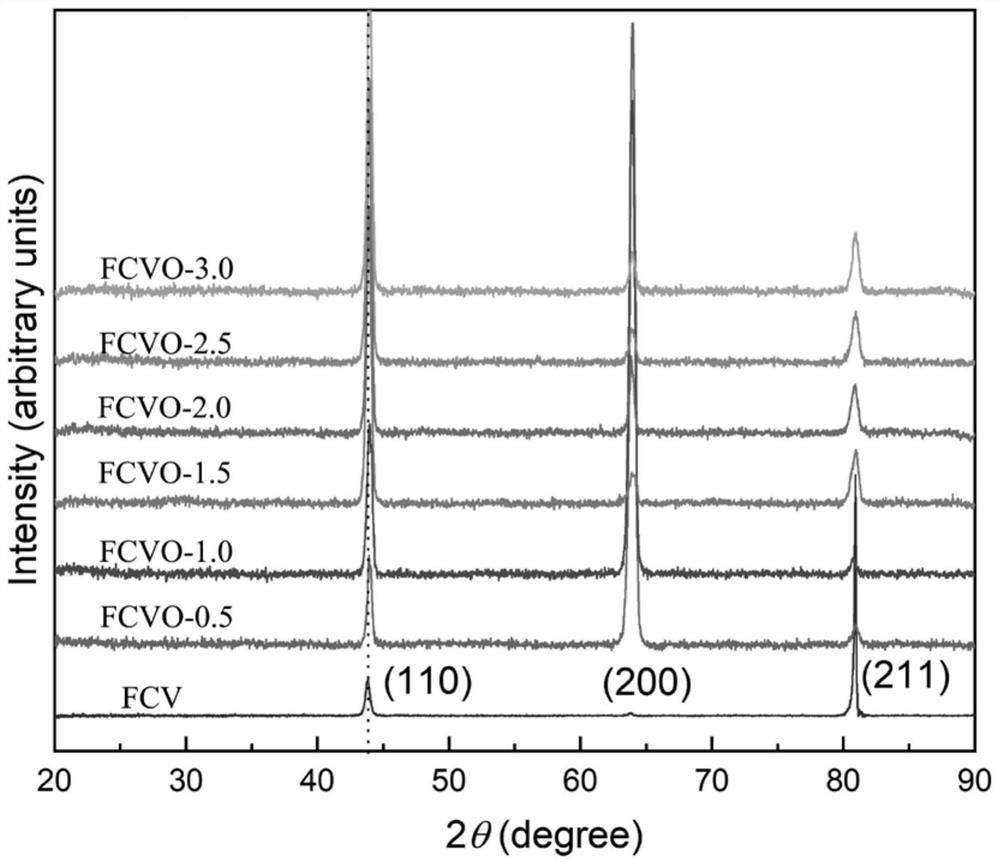

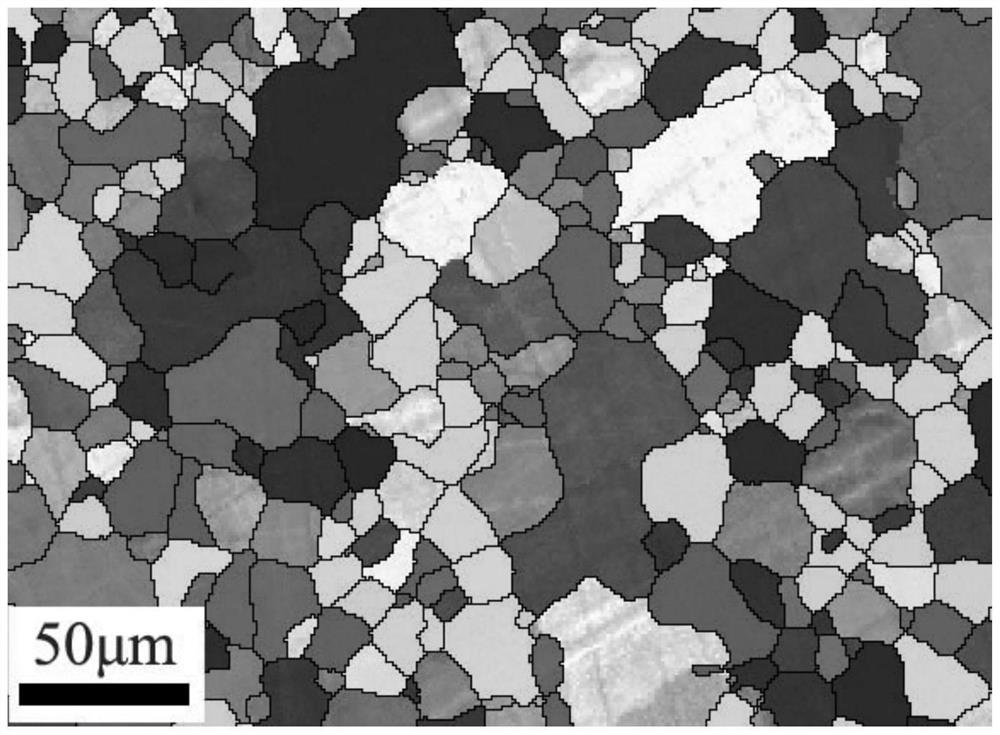

High-toughness low-activation FeCrVO multi-principal-element alloy and preparation method thereof

The invention relates to the field of nuclear energy structural materials and preparation, and provides a high-toughness low-activation FeCrVO multi-principal-element alloy and a preparation method thereof. The atomic percentage expression of the alloy is FeaCrbVcOd, a is larger than or equal to 20 and smaller than or equal to 35, b is larger than or equal to 20 and smaller than or equal to 35, cis larger than or equal to 20 and smaller than or equal to 35, d is larger than 0 and smaller than or equal to 3, and a + b + c + d = 100. The preparation process comprises the following steps of removing surface oxide skin of raw material Fe, Cr and V, accurately weighing according to a molar ratio, and adding an element O in a form of low-melting-point V2O5; and smelting a target alloy in a non-consumable vacuum arc furnace or a vacuum magnetic suspension smelting furnace, and obtaining the alloy through a vacuum suction casting or casting method. According to the preparation method, the strength and compression plasticity of the low-activation FeCrV multi-principal-element alloy are remarkably improved innovatively through adding the element O, and the comprehensive tensile property ofthe low-activation FeCrV multi-principal-element alloy is remarkably superior to that of an existing low-activation multi-principal-element alloy; and the alloy has high strength, high toughness, highthermal stability and excellent radiation resistance, and has an application prospect in the field of structural materials for nuclear energy.

Owner:PEKING UNIV

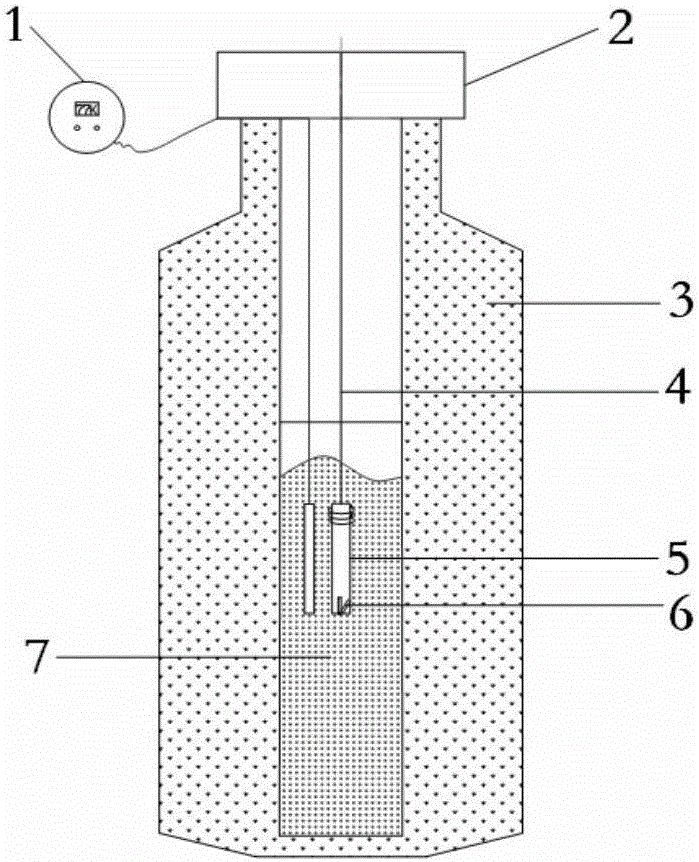

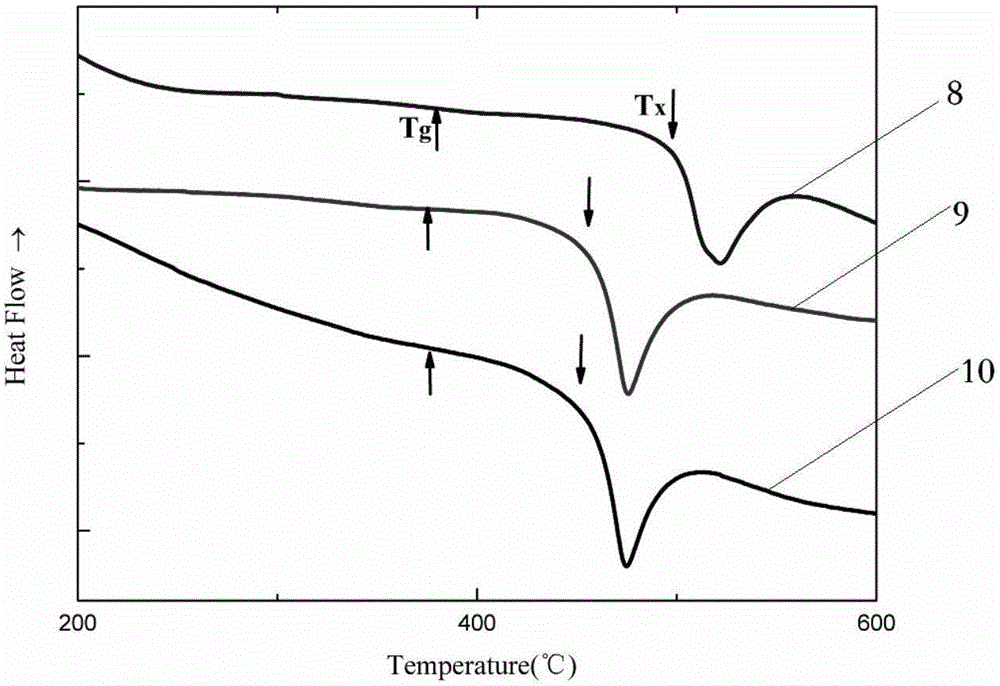

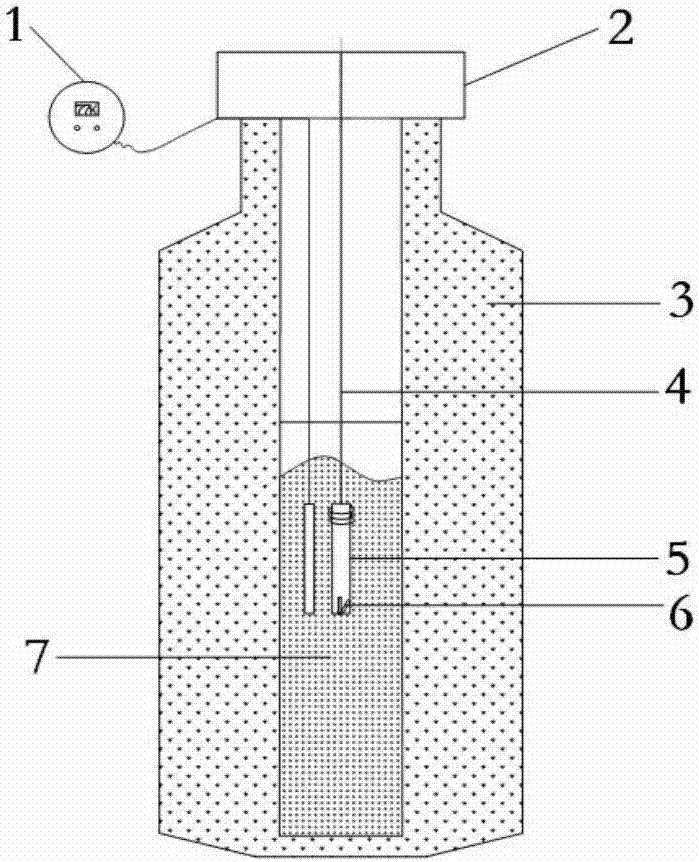

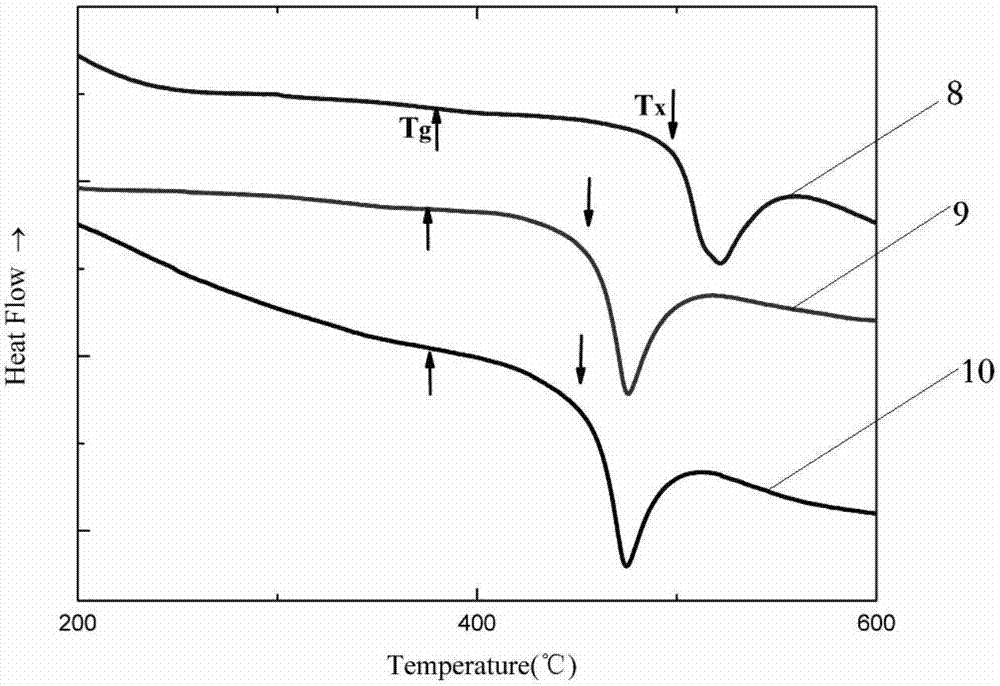

Method of regulating thermostability of Ti48Zr20Nb12Cu5Be15 amorphous composite

ActiveCN106011697AImprove thermal stabilityImprove anti-aging propertiesLiquid nitrogen containerAging resistance

The invention discloses a method of regulating the thermostability of a Ti48Zr20Nb12Cu5Be15 amorphous composite though low temperature cold treatment. A Ti48Zr20Nb12Cu5Be15 amorphous composite sample is put in a cold treatment device; the cold treatment device is put in a liquid nitrogen container to allow the Ti48Zr20Nb12Cu5Be15 amorphous composite sample in a quartz glass tube to be completely soaked in liquid nitrogen; when an indicator of a thermometer reaches 77K, the timing begins; and after being soaked for 1min to 1 week, the Ti48Zr20Nb12Cu5Be15 amorphous composite sample is taken out and stands at room temperature. The thermostability and aging resistance of the Ti48Zr20Nb12Cu5Be15 amorphous composite are improved. In addition, a low temperature atom relaxation condition is provided, so that the Ti48Zr20Nb12Cu5Be15 amorphous composite in a metastable state is turned to another Ti48Zr20Nb12Cu5Be15 amorphous composite in a metastable state having lower energy, the compressive plasticity of the Ti48Zr20Nb12Cu5Be15 amorphous composite is improved, and the Ti48Zr20Nb12Cu5Be15 amorphous composite has more excellent comprehensive mechanical properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

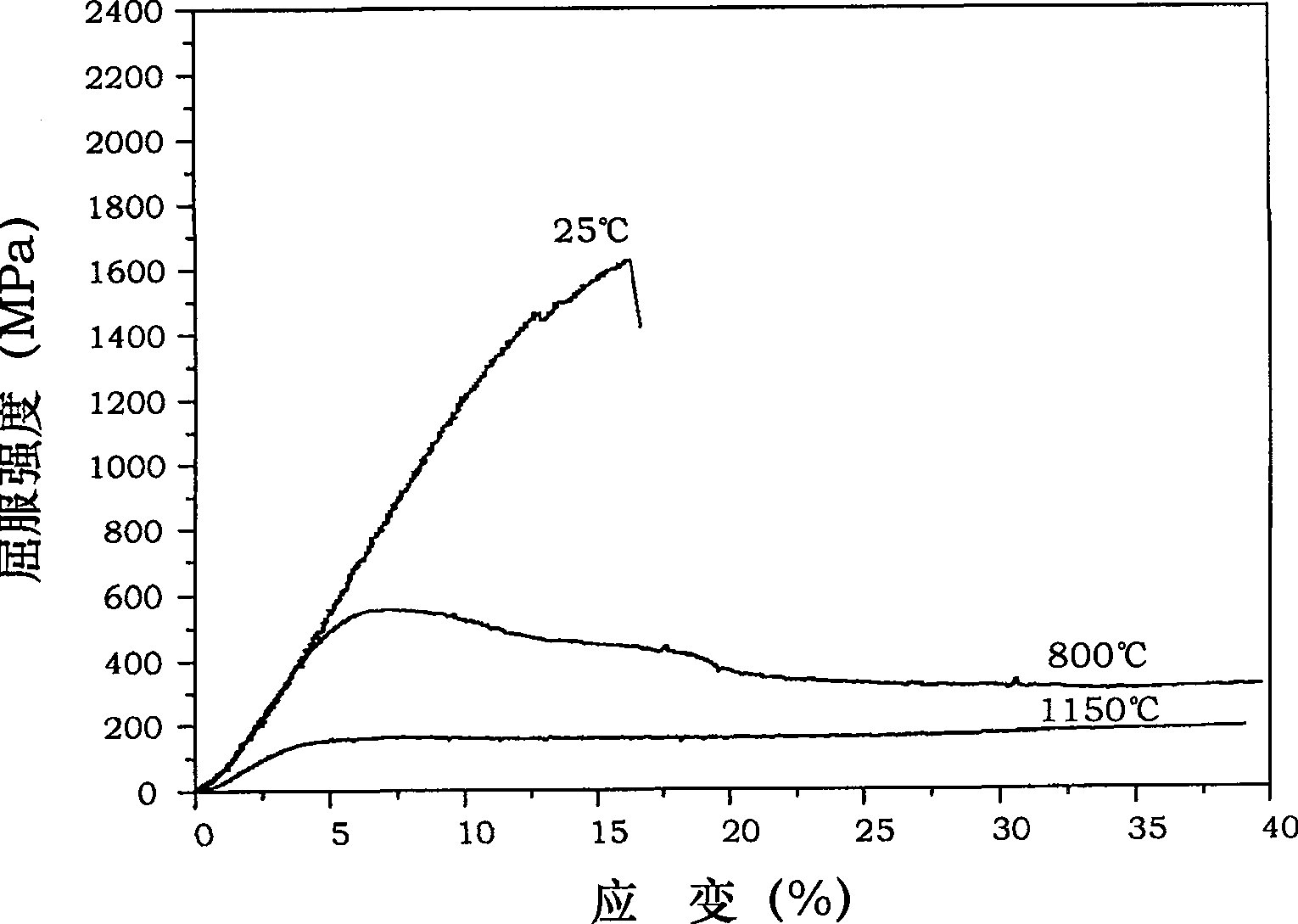

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by W

InactiveCN101148731AHigh temperature strengthImprove room temperature plasticityRoom temperatureUltimate tensile strength

The present invention discloses one kind of W modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, W in 1-15 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding W element to modify and form one pseudo binary eutectic phase with NiAl, the W modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The W modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 110-200 MPa and density of 6.8-7.8 g / cu cm.

Owner:BEIHANG UNIV

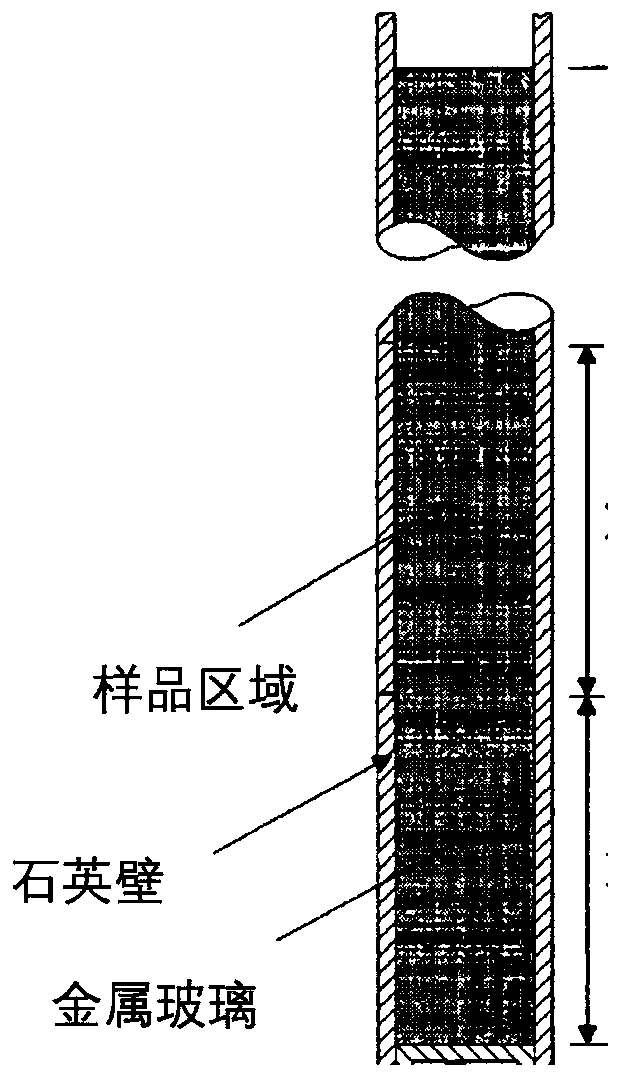

A kind of preparation method of flexible bulk metallic glass

The invention discloses a method for preparing a flexible bulk metallic glass, comprising the following steps: step 1, putting each raw material into a dry smelting device according to the alloy composition of the bulk metallic glass; in the presence of a protective gas, Prepare master alloy ingots after repeated smelting of each raw material; step 2, purify the master alloy ingot obtained in step 1 by using oxides as a purification medium; step 3, heat the quartz to a molten state to prepare a quartz mold; step 4 After sealing the quartz mold, place the purified master alloy ingot in the quartz mold, heat the master alloy ingot to melt in the presence of protective gas, press the molten metal into the quartz mold by air pressure, and make The molten metal is homogeneous and filled with the quartz mold, then taken out and immediately quenched in cold water, resulting in a flexible bulk metallic glass. The invention greatly improves the compressive plasticity of the bulk metallic glass, so that the metallic glass can flexibly bend without breaking at room temperature.

Owner:CHINA UNIV OF MINING & TECH

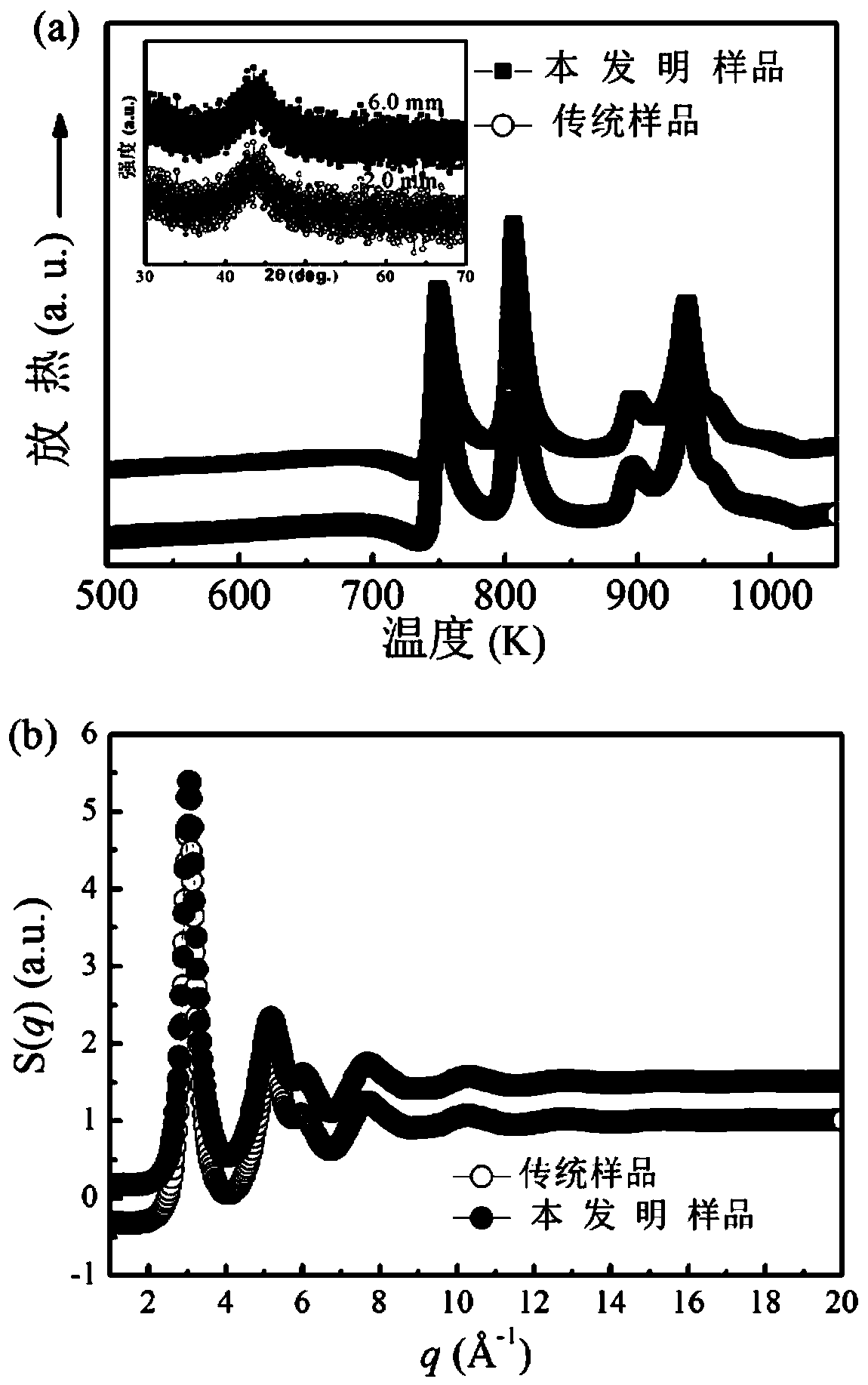

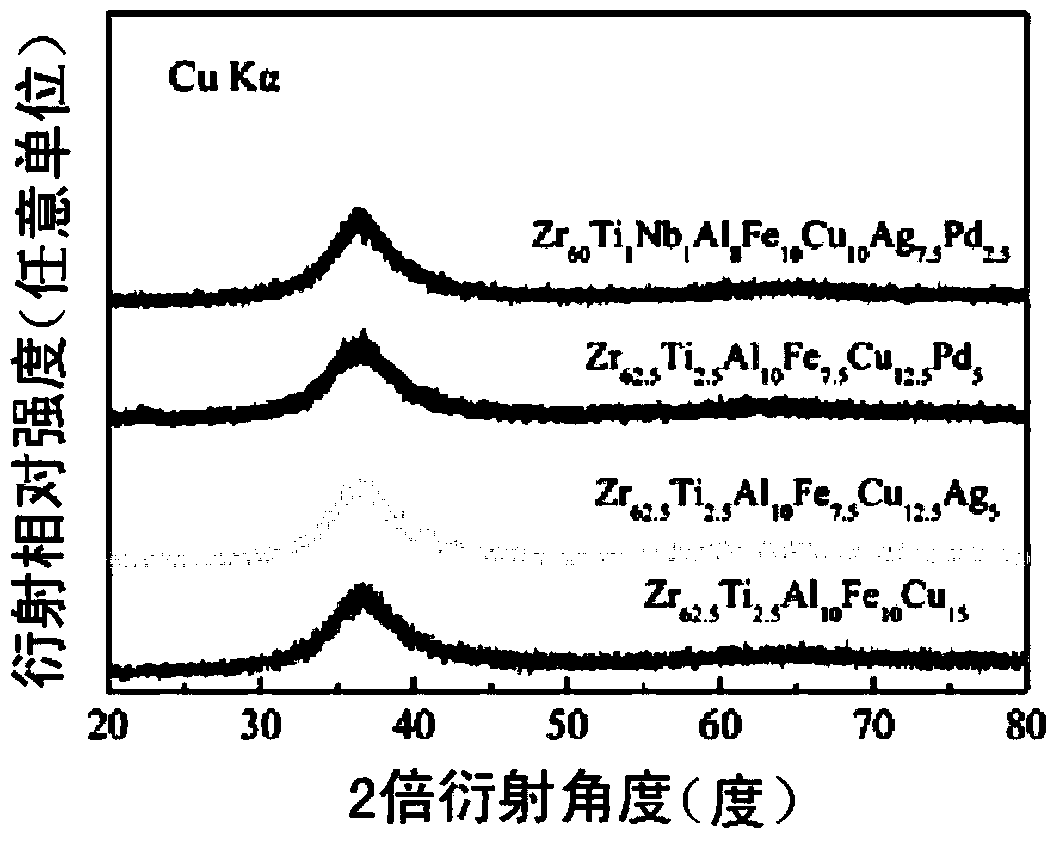

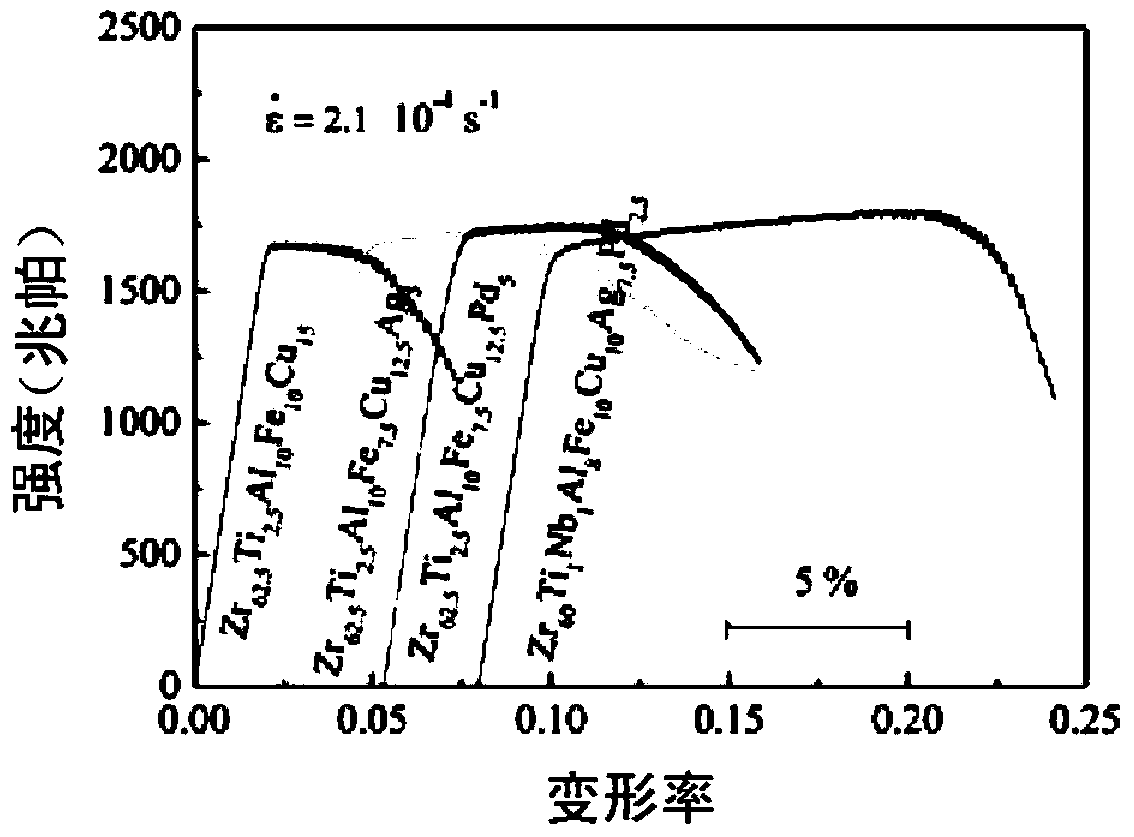

Nickel-free low-copper zirconium-based bulk amorphous alloy and preparation method thereof

The invention discloses a nickel-free low-copper zirconium-based bulk amorphous alloy and a preparation method thereof. The nickel-free low-copper zirconium-based bulk amorphous alloy comprises the following main components in atomic percentage: 60 to 70 percent of Zr, 1 to 2.5 percent of Ti, 0 to 2.5 percent of Nb, 7.5 to 12.5 percent of Al, 5 to 15 percent of Fe, 5 to 15 percent of Cu, 0 to 10 percent of Ag and 0 to 10 percent of Pd. The bulk amorphous alloy has high glass forming capacity, and a bulk amorphous alloy with the maximum critical diameter phi of 14mm can be prepared by a copper mold casting method; the bulk amorphous alloy does not contain metal element nickel, has the copper element content of less than 15 percent, and has a small copper ion precipitation quantity when serving as a biological material to be implanted in a body, and the potential biotoxicity is greatly reduced; and the bulk amorphous alloy has high biomechanical compatibility, low elastic modulus and high plasticity. Therefore, the series of amorphous alloy has wide application prospect in the fields such as structural materials, biomaterials, medical devices and the like.

Owner:BEIHANG UNIV

A Ti-based amorphous alloy with super-large amorphous forming ability and preparation method thereof

The invention belongs to the technical field of amorphous alloy materials, and relates to a Ti-Zr-Be-Ni-Cu(Fe) amorphous alloy with super large amorphous amorphous forming ability and a preparation method thereof. The composition of the Ti-based amorphous alloy is shown in the following general formula: (Ti a Zr b be c Ni d ) 100‑x Cu x or (Ti a Zr b be c Ni d ) 100‑x Fe x , where a, b, c, d, and x are all atomic percentages, and the value range is: 41≤a≤55, 15≤b≤25, 20≤c≤26, 8≤d≤10, 0

Owner:TSINGHUA UNIV

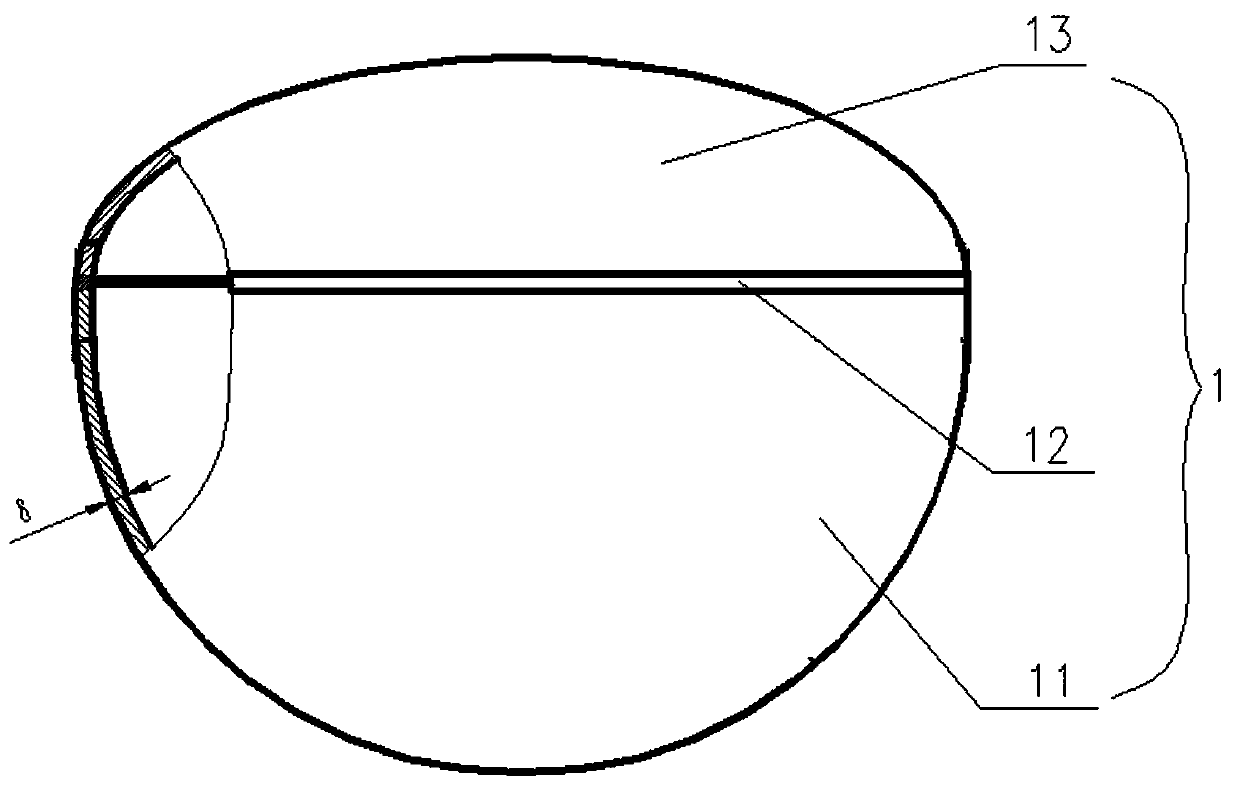

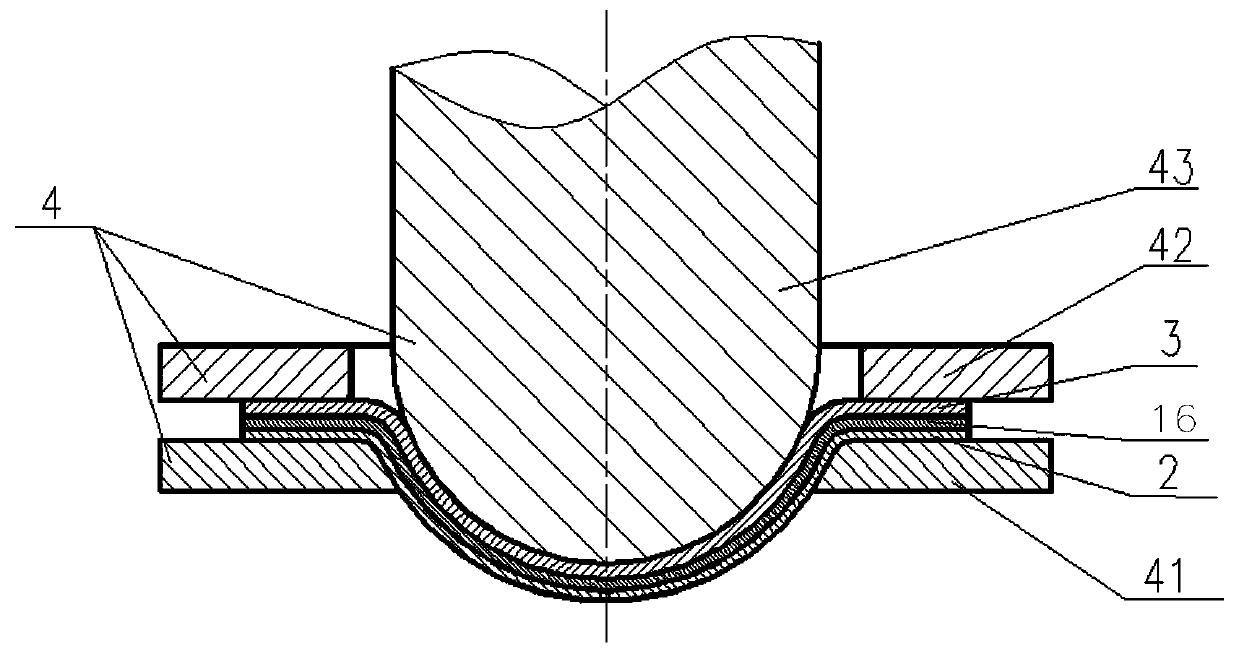

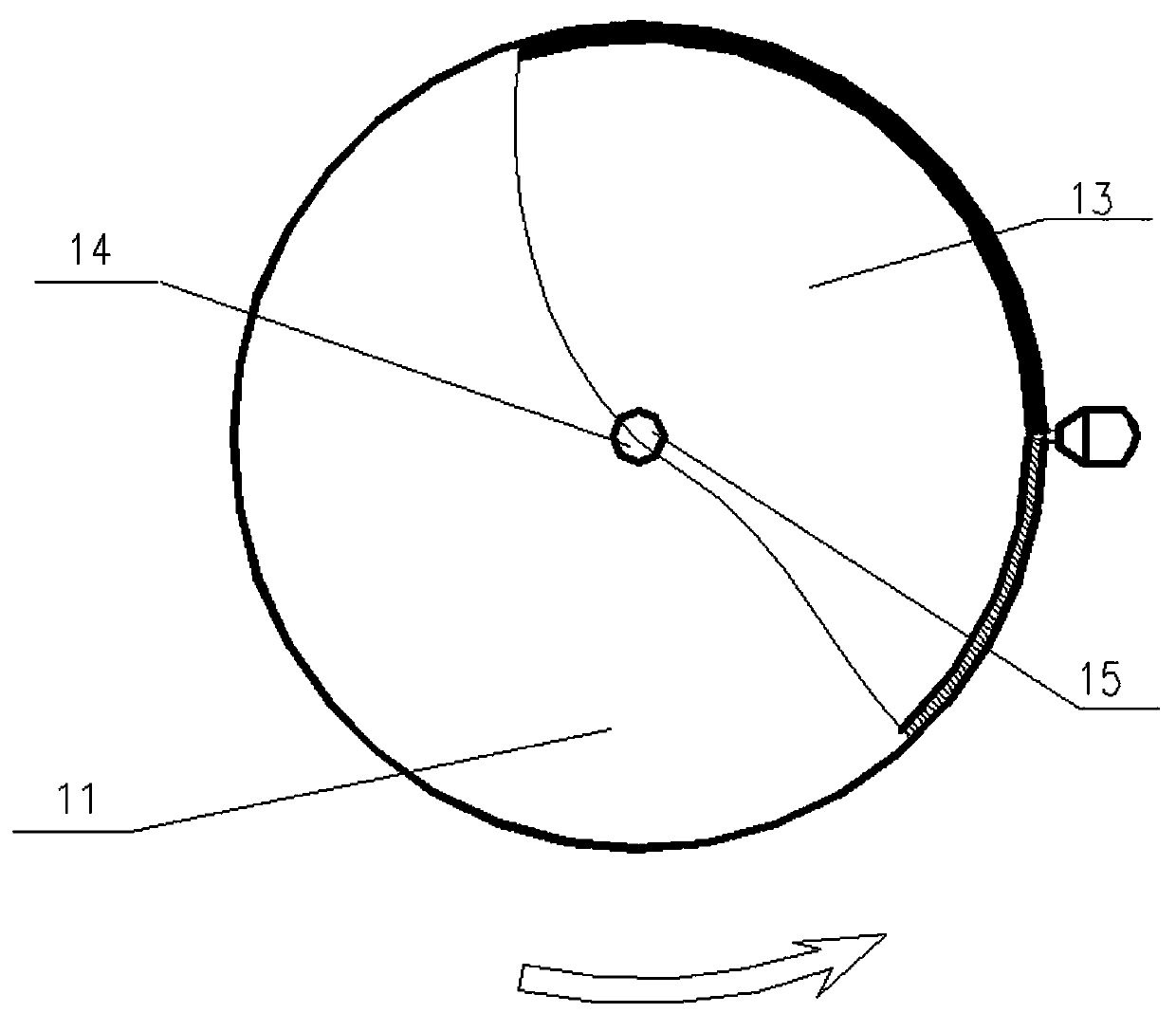

Manufacturing method of titanium or titanium alloy thin-wall ball shell

ActiveCN111515562AUniform temperature distributionReduce cooling rateArc welding apparatusPlasma welding apparatusTitanium alloyPlastic molding

The invention provides a manufacturing method of a titanium or titanium alloy thin-wall ball shell. The method includes the procedures of laying-off, plastic molding, groove machining, welding and nondestructive detection. During plastic molding, an assembly is formed in the manner that a ball shell plate is coated with two steel plates, a coating thermal molding process for thermoplastic moldingis carried out, temperature distribution during thermal pressing of the ball shell plate can be more uniform, the cooling speed of the ball shell plate can be effectively reduced, the pressing plasticity of the ball shell plate is improved, the pressing resistance is reduced, pits, bulges and the like generated in the molding process of the ball shell plate are avoided, the plastic deformation residual stress is small, the resilience value is small, and the dimensional precision of the obtained half-ball shell is greatly improved. In the welding process, the distances between a welding position and the top end of the ring surface of a weld joint and between the welding position and the bottom end of the ring surface of the weld joint are equal, in other words, the welding position is located in the middle of the circumferential direction of the ring surface of the weld joint instead of the top end of the ring surface of the weld joint, and therefore the phenomenon of oxidation of the back face of the weld joint can be completely avoided. Thus, the problem about manufacturing of the titanium thin-wall ball shell can be well solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by W

The invention discloses a W-modified NiAl-Cr(Mo) dual-phase eutectic intermetallic compound, the composition range of which is 33at% Ni, 30at% Cr, 4at% Mo, 1-15at% W and The balance of Al. In the composition range near the eutectic point of NiAl-Cr(Mo) double-phase eutectic, reduce the content of Al element, add W element for modification, and W element and NiAl form a pseudo-binary eutectic phase, plasticity at room temperature On the basis of Ni-rich NiAl-Cr(Mo) two-phase structure with good toughness, the introduction of appropriate W phase can further improve the high temperature strength and room temperature plasticity of eutectic intermetallic compounds. The density of the W-modified NiAl-Cr(Mo) dual-phase eutectic intermetallic compound of the invention is 6.8-7.8 g / cm3, and the yield strength at 1150 DEG C is 110-200 MPa.

Owner:BEIHANG UNIV

High-strength toughness low-activation fecrvo multi-principal element alloy and preparation method thereof

The present invention involves nuclear energy and preparation fields, providing a high -strong tough and low -activation FECRVO multi -primary element alloy and preparation method. The alloy atomic percentage expression FE a CR b V c O d , 20≤A ≤ 35, 20≤b ≤ 35, 20≤c ≤ 35, 0 <d≤3, A+B+C+D = 100.Preparation process: Remove the surface oxidation of the raw material FE, CR, V, accurately weigh the Moore ratio, and O element with a low melting point V 2 O 5 Add in the form; melted target alloys in non -self -consuming real vacuum arc furnaces or real vacuum suspended melt furnaces, and obtained alloys with vacuum suction or casting method.The invention innovatively improves the strength and compression of the FECRV multi -primary metal alloy by adding O elements. The comprehensive stretching performance is significantly better than the existing low -activated multi -main metal alloys;Sexual and excellent radiation resistance, with application prospects in the field of nuclear energy.

Owner:PEKING UNIV

regulate ti 48 zr 20 nb 12 cu 5 be 15 Method for Thermal Stability of Amorphous Composites

ActiveCN106011697BImprove thermal stabilityImprove anti-aging propertiesLiquid nitrogen containerCold treatment

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A preparation method of Ti-based high-entropy amorphous-dendrite composite material

The invention provides a preparation method of a Ti-based high-entropy amorphous-dendritic composite material. The preparation method is mainly characterized in that Ti20Zr20Hf20Nb10Cu10Be20 of a predesigned alloy proportion is alloyed through a vacuum electric-arc furnace, and comprises the following steps that elementary substance elements with the purity being larger than or equal to 99.9% areweighed according to the atom proportion of Ti25Zr25Hf25Nb25, smelting is carried out, and thus a first intermediate alloy is obtained; then elementary substance elements are weighed according to theatom proportion of Ti16.67Zr16.67Hf16.67Cu16.67Be16.67, smelting is carried out, and thus a second intermediate alloy is obtained; and finally the first intermediate alloy and the second intermediatealloy are subjected to mixed smelting and suction-casting, and thus the high-entropy amorphous-dendritic composite material Ti20Zr20Hf20Nb10Cu10Be20 is obtained. The preparation method provided by theinvention is simple and easy to operate, the compression performance of the obtained composite material is significantly improved, and the method is suitable for industrial production and popularization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

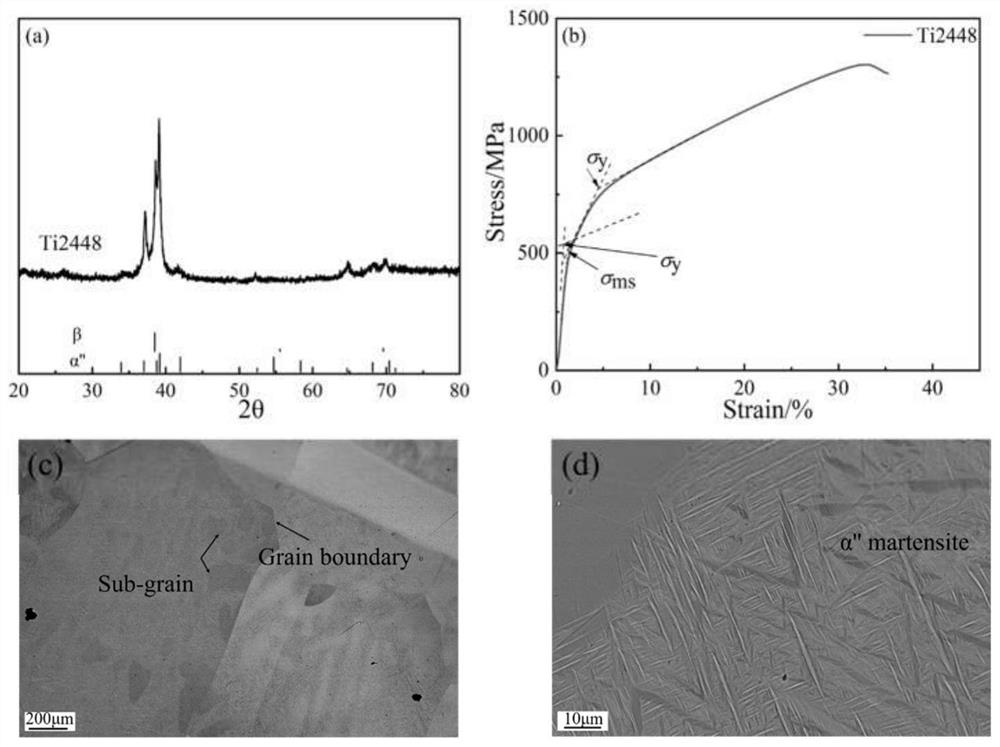

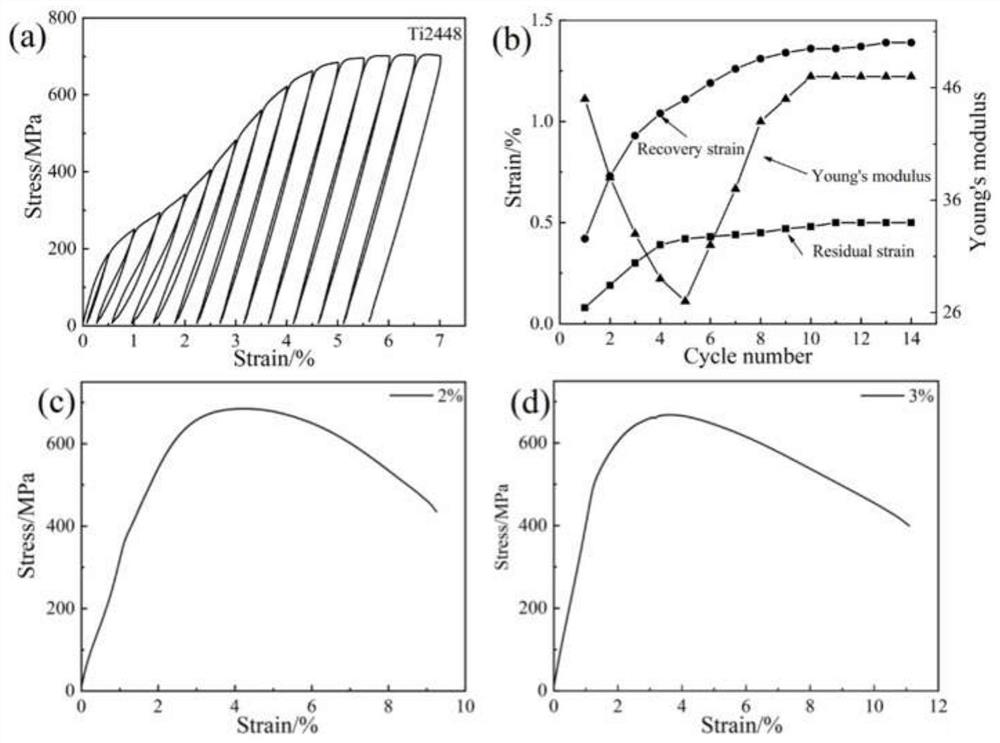

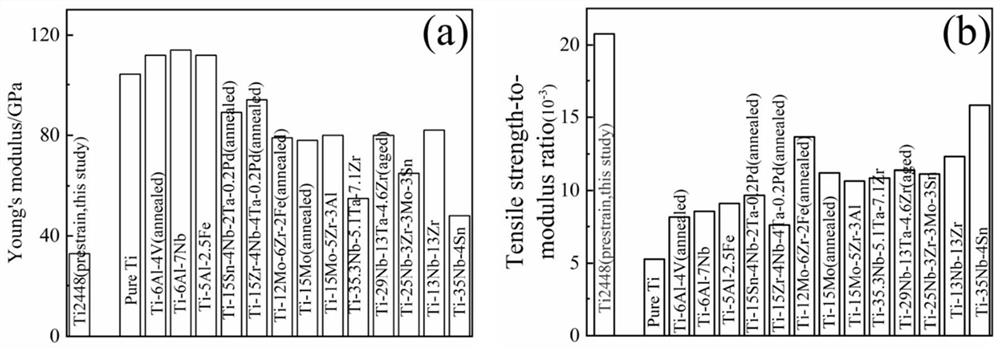

A preparation method of ti2448 biomedical alloy with low Young's modulus

ActiveCN113337744BHigh compressive strengthImprove compression plasticityProsthesisSolution treatmentPhysical chemistry

The invention discloses a preparation method of Ti2448 biomedical alloy with low Young's modulus. The preparation process includes the following steps: mixing Ti, Nb, Zr and Sn simple substances according to the mass fraction, performing electric arc melting, and rolling the cast ingot by adopting three different rolling process parameters. In order to eliminate internal stress, the plate is subjected to solution treatment at 850°C and water quenched, and then the Young's modulus of the alloy is reduced by adding appropriate pre-strain. Compared with the prior art, the present invention successfully reduces the Young's modulus of the Ti2448 alloy to 33GPa and optimizes the comprehensive mechanical properties of the alloy through appropriate thermomechanical treatment parameters and adding appropriate pre-strain.

Owner:SHANGHAI UNIV

Preparation method of multifunctional metal/metallic glass blended fabric with enhanced stretching

InactiveCN108677321AImprove compression plasticityHigh elongation at breakWoven fabricsSolventCopper plating

The invention provides a preparation method of multifunctional metal / metallic glass blended fabric with enhanced stretching. The method includes the following steps that mother alloy powder obtained by preparing Pd powder, Cu powder, Ni power and P powder is smashed into pieces, the pieces are added into a graphene oxide water solution, the mixture is stirred to volatize solvent, then the mixtureis added into vacuum heating and solidifying equipment in batch, under the atmosphere of inertial gas, the metallic glass mixture to be subjected to graphene oxide modification is totally fused, andthen a spinning solution is obtained; the spinning solution is put into a melt spinning device, a supercooling liquid phase region of metallic glass is set to have a forming temperature, and a PdCuNiPmetallic glass fiber is obtained through pressurizing and extruding; one end of the PdCuNiP metallic glass fiber is connected with a rotating device, the other end of the PdCuNiP metallic glass fiberis put into a copper sulfate electrolyte to serve as a cathode, a copper plate is used as an anode, rotating for copper plating is performed, and then an enhanced-stretching metallic glass fiber wrapped with copper is obtained; the enhanced-stretching metallic glass fiber wrapped with copper and the metallic fiber are subjected to blending, and therefore the multifunctional metal / metallic glass blended fabric with enhanced stretching is prepared.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

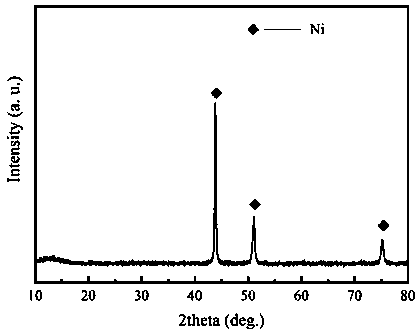

Preparation method of high-strength and long-life porous nickel-based solid solution for electrolytic hydrogen production

A preparation method of high-strength and long-life porous nickel-based solid solution for electrolytic hydrogen production, using powder metallurgy microwave sintering method, using Mg powder as a pore-forming agent, and passing ultrafine Fe, Co, Ni powder and Mg powder with different content ratios After ball milling, press molding, and high temperature (>700°C) microwave sintering to make porous nickel-based solid solution. The porous nickel-based solid solution of the present invention has the advantages of three-dimensional open pore structure, high permeability, high strength, large specific surface area, excellent electrical conductivity, etc., and can form high catalytic The multi-component composite oxide active site with high performance is suitable for oxygen evolution electrode for hydrogen production by water electrolysis.

Owner:NANCHANG HANGKONG UNIVERSITY

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Zr

The present invention discloses one kind of Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Zr in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Zr element to modify and form one Heusler(L21-Ni2AlZr) phase with NiAl, the Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 110-130 MPa and density of 6.1-6.7 g / cu cm.

Owner:BEIHANG UNIV

Ti-based block amorphous alloy with great amorphous forming ability and preparation method thereof

The invention discloses a Ti-based block amorphous alloy with a great amorphous forming ability and a preparation method thereof. The composition of the Ti-based block amorphous alloy is shown as the following general formula: (Ti66-xZrxBe34-yFey)100-zCuz, wherein, x, y and z are atomic percentage (*100), and have the value ranges that: x is greater than or equal to 20 and smaller than or equal to 26, y is greater than 0 and smaller than or equal to 12, and z is greater than or equal to 0 and smaller than or equal to 12. The preparation method of the Ti-based block amorphous alloy consists ofthe steps of: converting the atomic percent of the components in the Ti-based block amorphous alloy into mass percent, and weighing out raw materials; mixing and melting the raw materials under vacuum or gas protection and making a master alloy ingot; melting the master alloy ingot which is then put into an oxygen-free copper die through suction casting or spray casting, thus obtaining the Ti-based block amorphous alloy. The preparation method of the invention can prepare Ti-based block amorphous alloys with a good amorphous forming ability and a low density at a low cost.

Owner:TSINGHUA UNIV

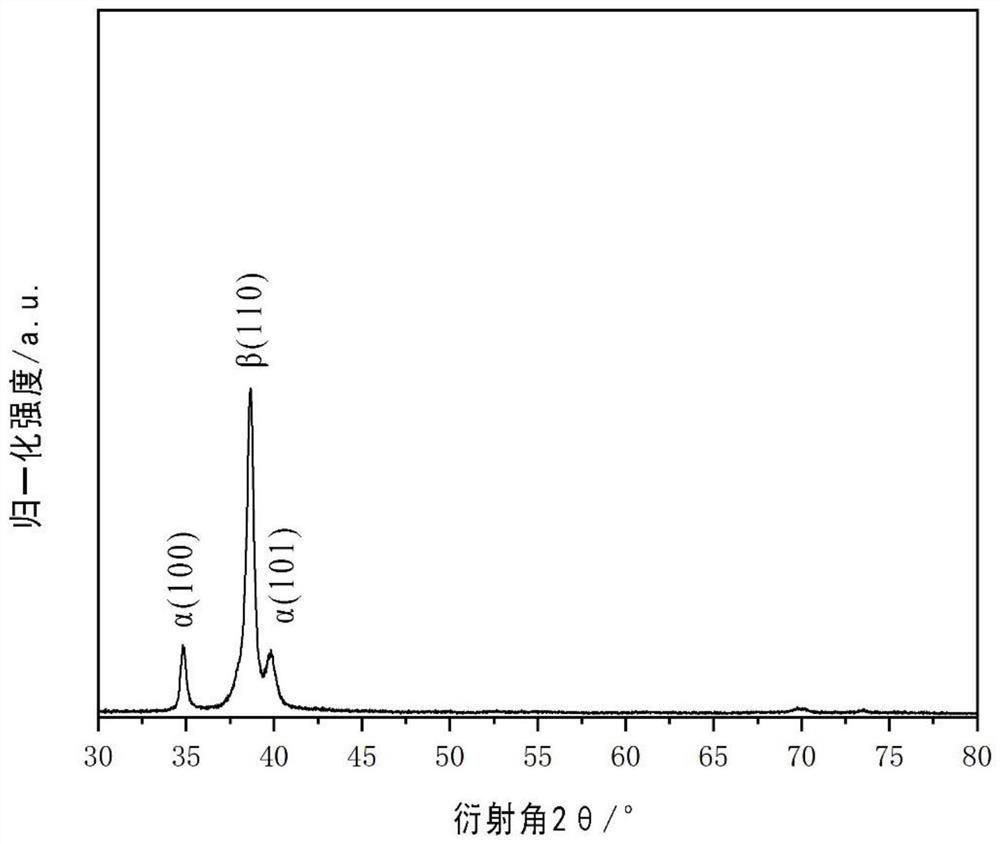

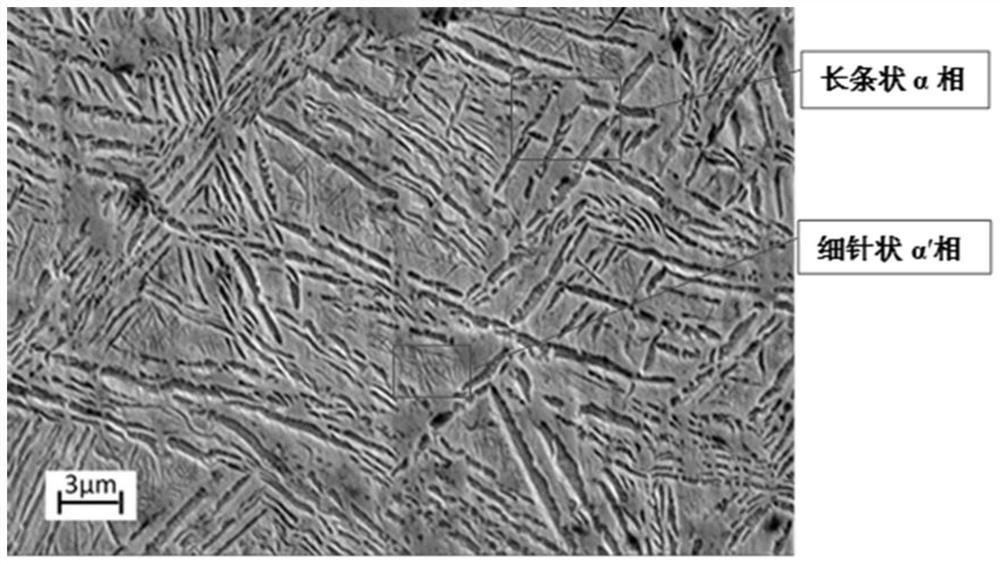

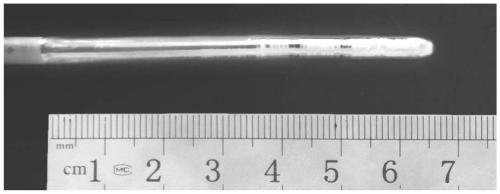

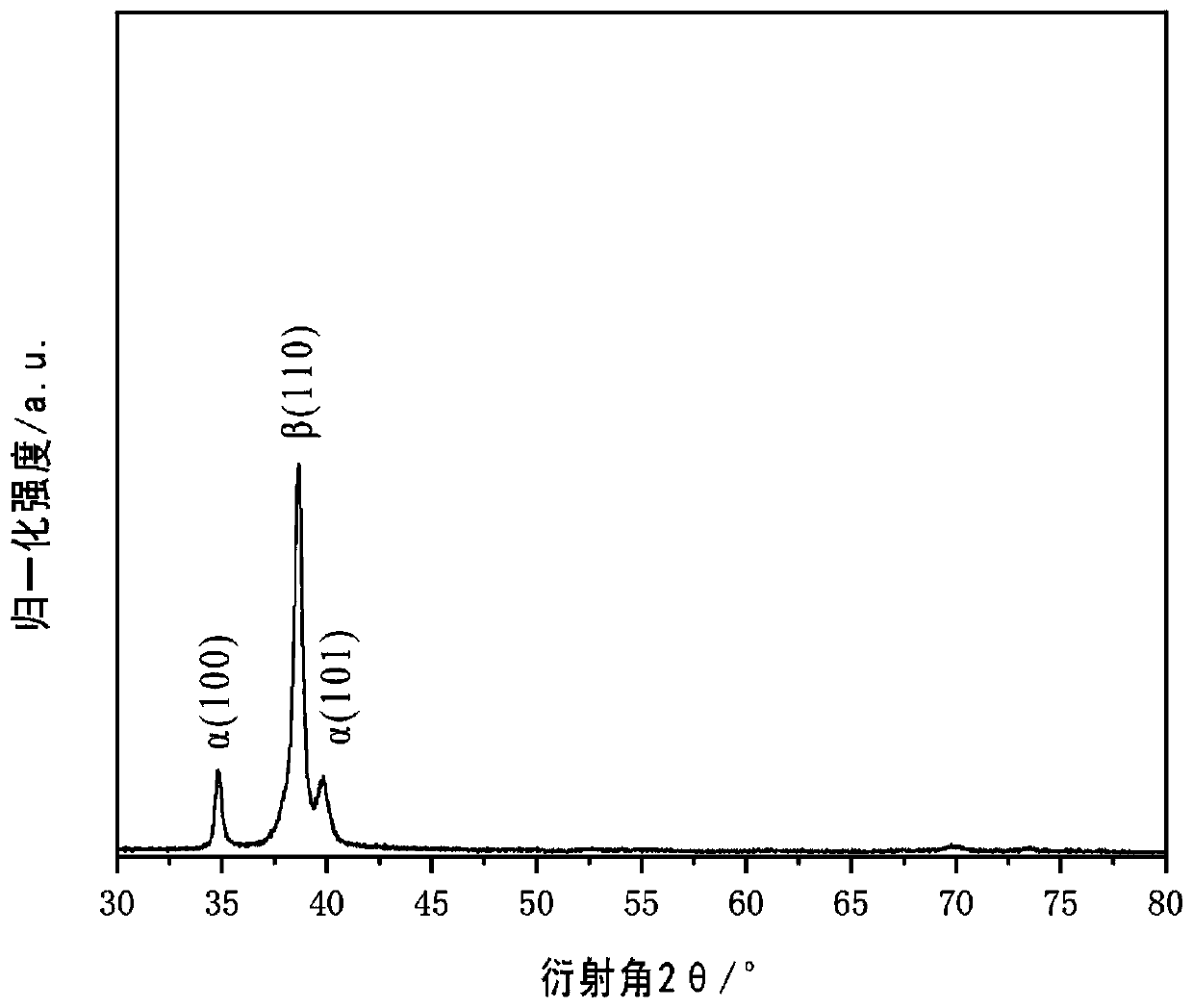

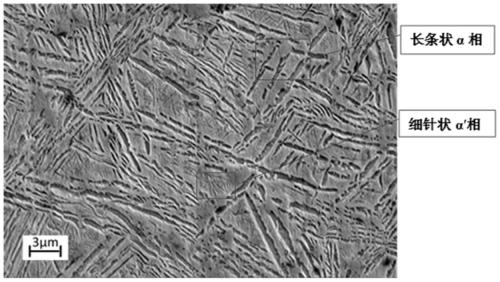

A preparation method and single crystal of β-phase ti2448 biomedical alloy containing α+α′ phase

ActiveCN111286786BHigh compressive strengthImprove compression plasticityPolycrystalline material growthBy zone-melting liquidsSingle crystalCondensed matter physics

The invention discloses a preparation method of an alpha+alpha' phase-containing beta-phase Ti2448 biomedical alloy single crystal and the single crystal, wherein the preparation method comprises thesteps: S1, pressing prepared alloy powder into material rods by using a hydrostatic pressure method, and sintering the material rods into polycrystalline rods; and S2, fixing the polycrystalline rod to each of the upper end and the lower end of a ultra-high-temperature optical floating zone furnace, and enabling the other ends of the two rods to be close to each other in a heating zone; sealing afurnace, simultaneously rotating the two rods in the same direction or opposite directions, quickly heating to melt two end points, controlling the rotating speed to stably melt, and butting to form astable melting area; and then moving the heating area for crystal growth, powering off and naturally cooling to room temperature after the crystal growth is finished, and taking out the Ti2448 singlecrystal rod. Compared with the prior art, the method has the advantages that the crystal growth process is simple, the repeatability is high, the single crystal grown by using the optical floating zone method is free of macroscopic defects and has the diameter of centimeter level, the strength and plasticity of the Ti2448 biomedical alloy single crystal material are greatly improved, and the lowelastic modulus is maintained.

Owner:SHANGHAI UNIV

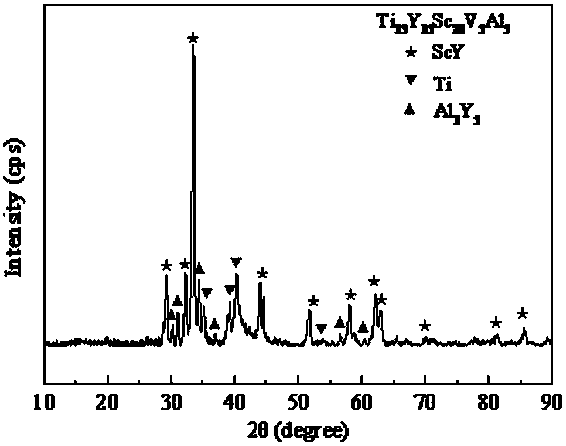

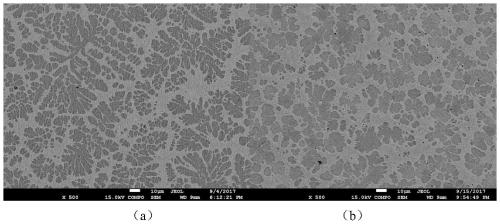

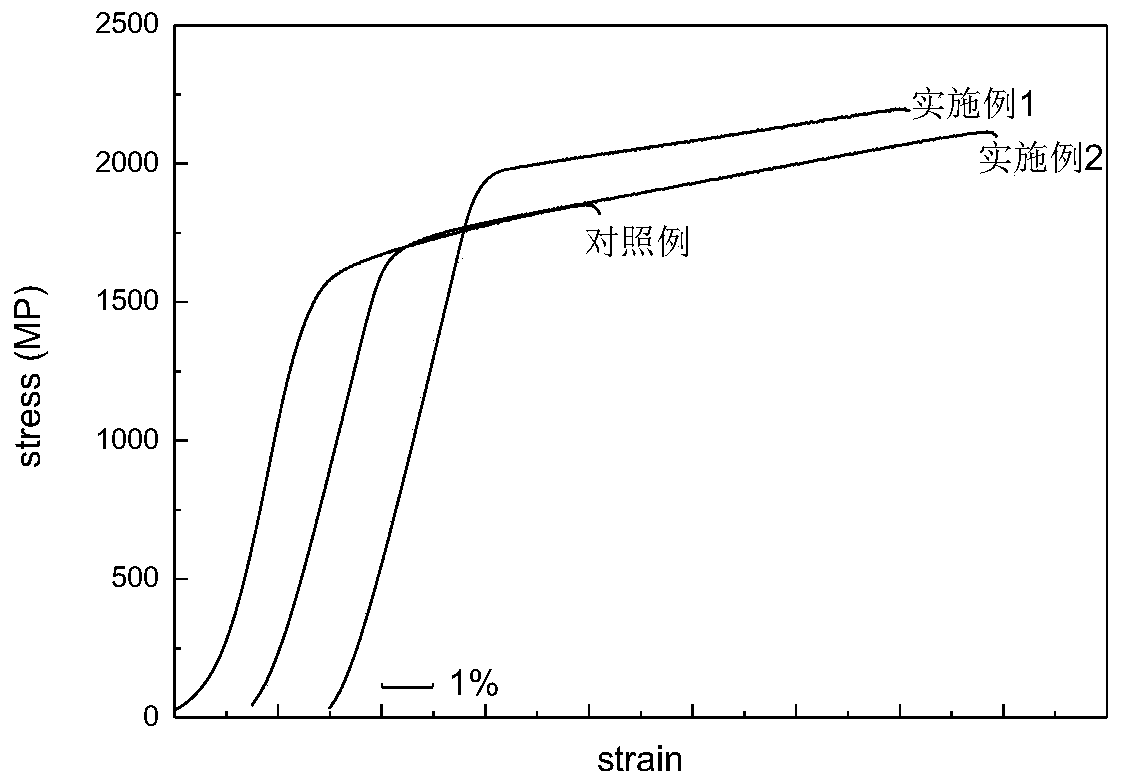

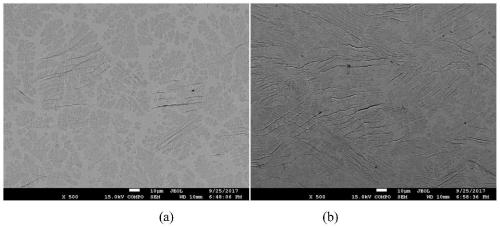

a lightweight ti 35 the y 35 sc 20 v 5 al 5 High entropy alloy and its preparation method

The invention discloses a light Ti35Y35Sc20V5Al5 high-entropy alloy and a preparation method thereof, and belongs to the technical field of light high-entropy alloy material. A vacuum arc is used forsmelting. An INSTRON mechanical experiment machine and a Hopkinson pressure bar are used for respectively conducting a quasi-static compression test with strain rate of 1*10<-3>s<-1> and a dynamic compression test with strain rate of 1500 s<-1>. The crystal structure is analyzed by X-ray diffraction. Composition and distribution of a phase are determined by energy spectrum analysis. A scanning electron microscopy is used for observing the microstructure of a specimen at the fracture surface, and the fracture model is the brittle fracture mode. The high-entropy alloy is a high-entropy solid solution phase with dense hexagonal structure. Under the condition of high strain rate, the yield strength and plasticity of the material are improved. The material exhibits excellent impact toughness.

Owner:TAIYUAN UNIV OF TECH

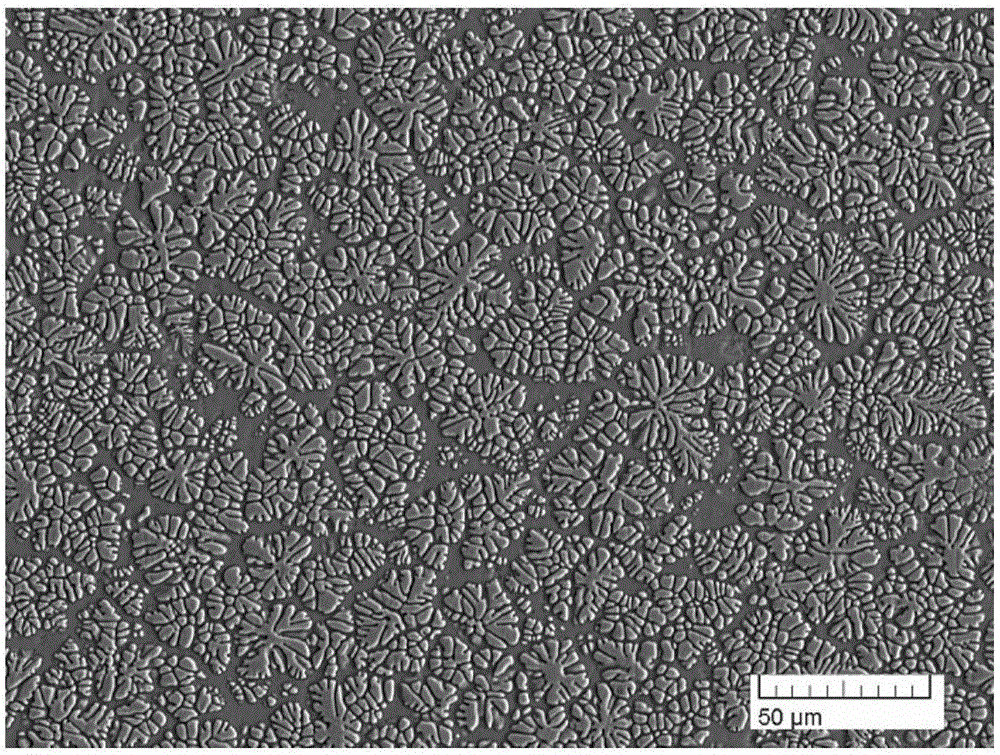

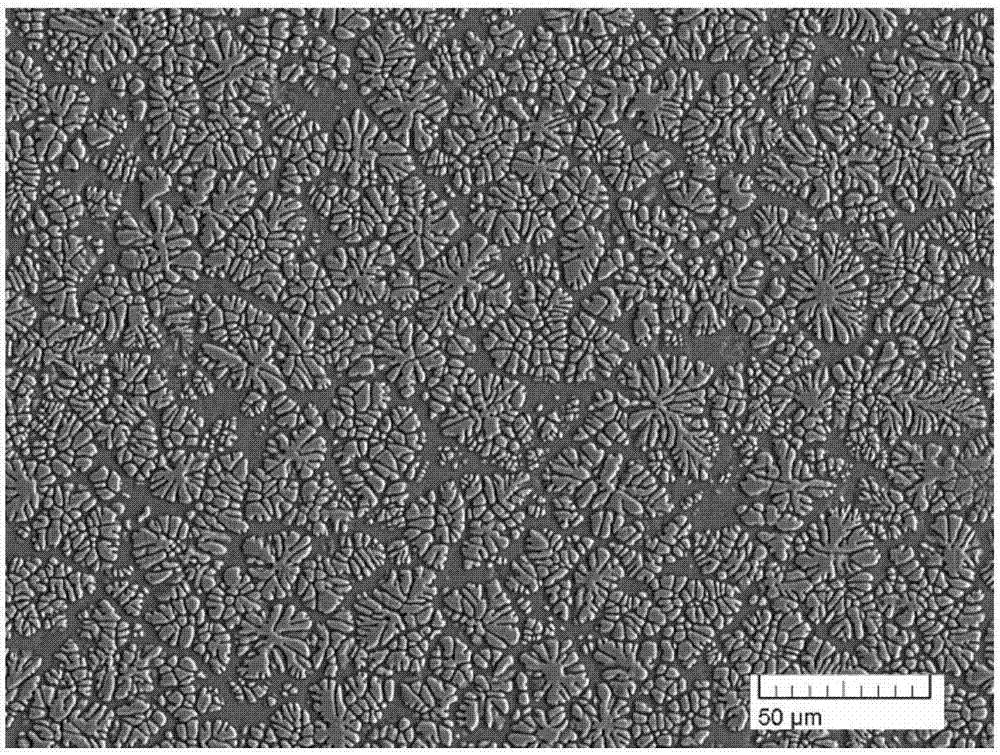

Amorphous composite material with oxygen-modulated phase transition and preparation method thereof

ActiveCN108715979BInhibition of β→α" phase transitionControl mechanical propertiesShape changeMetallic materials

The invention belongs to the technical field of metal materials, and discloses an amorphous composite material with phase transition modulated by oxygen and a preparation method thereof. The main chemical composition of the composite material is Ti a Zr b Ni c Cu d be e o f , where a, b, c, d, e and f are the atomic percentages of the corresponding elements, 31≤a≤63, 26≤b≤40, 0.1≤c≤6, 1≤d≤10, 1≤e≤22, 0.1≤f≤6, and a+b+c+d+e+f=100; the material is a type of amorphous composite material with deformation-induced martensitic transformation. The method is mainly to add the oxide of metal M to the alloy during smelting to realize the addition of O element, and M is one or more of Ti, Zr and Cu. The addition of O element can effectively modulate the dynamic characteristics and distribution of deformation-induced martensitic transformation, so that the amorphous composite material exhibits excellent comprehensive mechanical properties such as high strength, large plasticity and good work hardening ability. The invention has important guiding significance for the industrial production and practical application of the amorphous alloy and its composite material.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of alpha+alpha' phase-containing beta-phase Ti2448 biomedical alloy single crystal and single crystal

ActiveCN111286786AHigh compressive strengthImprove compression plasticityPolycrystalline material growthBy zone-melting liquidsSingle crystalCondensed matter physics

The invention discloses a preparation method of an alpha+alpha' phase-containing beta-phase Ti2448 biomedical alloy single crystal and the single crystal, wherein the preparation method comprises thesteps: S1, pressing prepared alloy powder into material rods by using a hydrostatic pressure method, and sintering the material rods into polycrystalline rods; and S2, fixing the polycrystalline rod to each of the upper end and the lower end of a ultra-high-temperature optical floating zone furnace, and enabling the other ends of the two rods to be close to each other in a heating zone; sealing afurnace, simultaneously rotating the two rods in the same direction or opposite directions, quickly heating to melt two end points, controlling the rotating speed to stably melt, and butting to form astable melting area; and then moving the heating area for crystal growth, powering off and naturally cooling to room temperature after the crystal growth is finished, and taking out the Ti2448 singlecrystal rod. Compared with the prior art, the method has the advantages that the crystal growth process is simple, the repeatability is high, the single crystal grown by using the optical floating zone method is free of macroscopic defects and has the diameter of centimeter level, the strength and plasticity of the Ti2448 biomedical alloy single crystal material are greatly improved, and the lowelastic modulus is maintained.

Owner:SHANGHAI UNIV

Method and system for improving compression plasticity of amorphous alloy

InactiveCN101717902BImprove compression plasticityImprove plastic deformation abilityDiameter ratioDistortion

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com