A preparation method of Ti-based high-entropy amorphous-dendrite composite material

A composite material and high-entropy technology, which is applied in the field of preparation of Ti-based high-entropy amorphous-dendrite composite materials, can solve the problems of dendrite-amorphous composite materials such as difficulties, and achieve easy preparation, improved compression plasticity, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

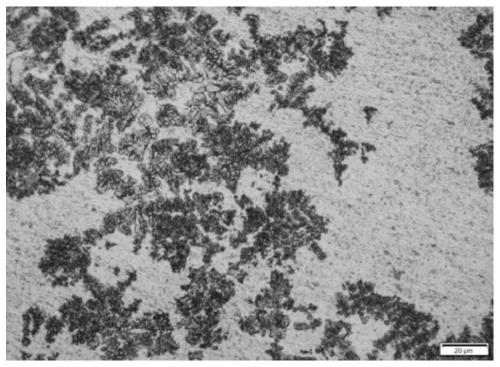

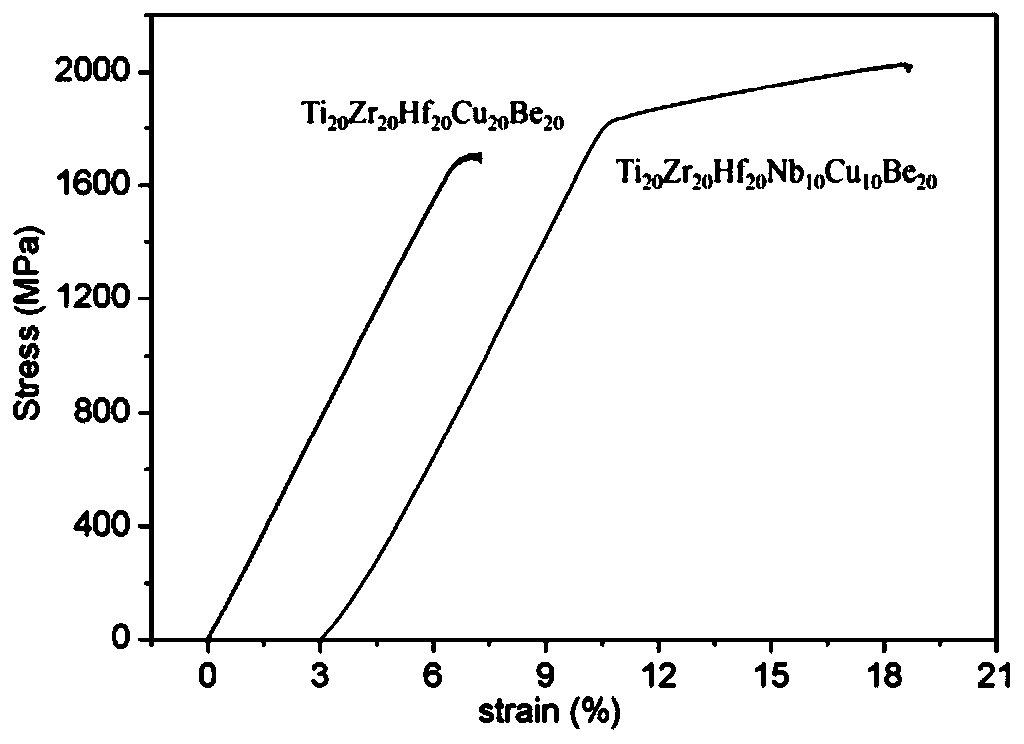

Image

Examples

Embodiment 1

[0026] A Ti-based high-entropy amorphous-dendritic composite material Ti 20 Zr 20 f 20 Nb 10 Cu 10 be 20 The preparation method comprises the following steps:

[0027]S1. Surface treatment of raw materials: each elemental element Ti, Zr, Hf, Nb, Cu, and Be with a purity greater than or equal to 99.9% was ultrasonically cleaned with acetone and ethanol for 20 minutes, and dried with a hair dryer, and then weighed according to the following mass Take the treated elements: 4.73g Ti, 9.02g Zr, 17.63g Hf, 4.59g Nb, 3.14g Cu and 0.89g Be;

[0028] S2. Alloy smelting: according to Ti 25 Zr 25 f 25 Nb 25 Weigh 4.76g Ti, 8.89g Zr, 17.40g Hf and 9.05g Nb respectively into a water-cooled copper crucible and place it in a vacuum electric arc furnace. Close the furnace door and draw a vacuum to 1*10 -3 MPa, and then filled with 0.3MPa high-purity argon gas. After arcing, the titanium ingot was smelted three times to absorb the residual oxygen in the furnace, and then the mixed ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com