Preparation method of multifunctional metal/metallic glass blended fabric with enhanced stretching

A technology of metallic glass and blended fabrics, applied in textile, textile, papermaking, fabrics and other directions, can solve the problems of hindering the slippage of the main shear belt, unstable metallic glass fibers, etc. The effect of elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

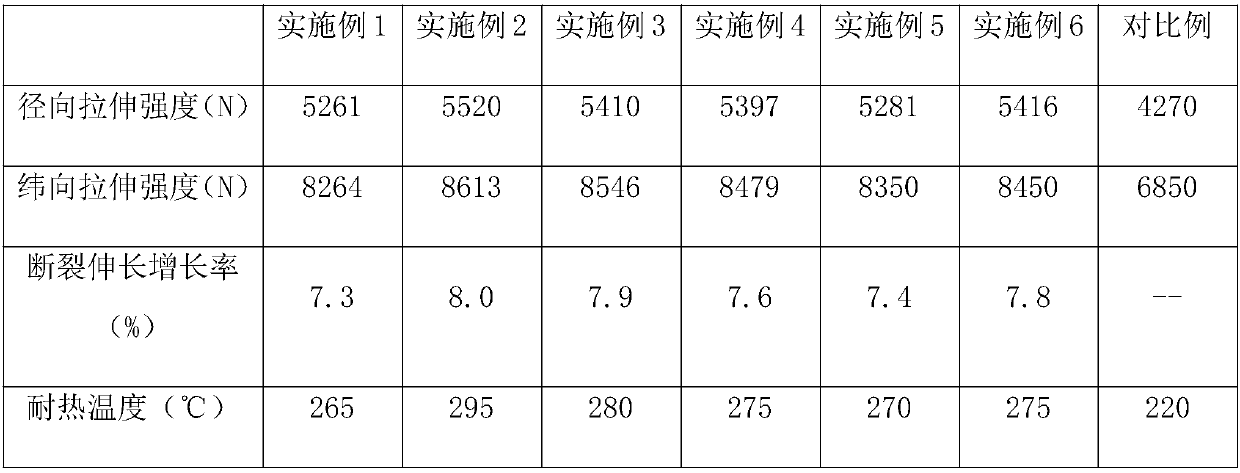

Examples

Embodiment 1

[0025] (1) Pd powder with a purity ≥ 99.9%, Cu powder with a purity ≥ 99.9%, Ni powder with a purity ≥ 99.9% and P powder with a purity ≥ 99.9% in a mass ratio of 35:25:10:15 at 0.03MPa Under vacuum conditions, first raise the temperature to 900°C, hold for 5 minutes, then raise the temperature to 1600°C, hold for 15 minutes, then cool down to 1000°C, hold for 10 minutes, then raise the temperature to 1450°C, hold for 20 minutes, and then place it at room temperature to obtain the master alloy , crush the master alloy into pieces and add it to a 10mg / mL graphene oxide aqueous solution. After mixing evenly, stir the volatile solvent to obtain a graphene oxide modified metallic glass mixture, wherein the graphene oxide modified metallic glass mixture is oxidized The content of graphene is 0.01wt%.

[0026] (2) Add the metallic glass mixture modified by graphene oxide into the vacuum heating and curing equipment in batches, and under an inert gas atmosphere, melt all the metallic...

Embodiment 2

[0031] (1) Pd powder with a purity of ≥99.9%, Cu powder with a purity of ≥99.9%, Ni powder with a purity of ≥99.9%, and P powder with a purity of ≥99.9% at a mass ratio of 42:30:15:20 at 0.05 MPa Under vacuum conditions, first raise the temperature to 1000°C, keep it for 10 minutes, then raise the temperature to 1650°C, keep it for 20 minutes, then cool it down to 1050°C, keep it for 15 minutes, then raise the temperature to 1550°C, keep it for 30 minutes, and then put it at room temperature to get the master alloy , crush the master alloy into pieces and add it to a 15mg / mL graphene oxide aqueous solution. After mixing evenly, stir the volatile solvent to obtain a graphene oxide modified metallic glass mixture, wherein the graphene oxide modified metallic glass mixture is oxidized The content of graphene is 0.05wt%.

[0032] (2) Add the graphene oxide-modified metallic glass mixture in batches to the vacuum heating and curing equipment, and under an inert gas atmosphere, melt...

Embodiment 3

[0037] (1) Pd powder with a purity of ≥99.9%, Cu powder with a purity of ≥99.9%, Ni powder with a purity of ≥99.9%, and P powder with a purity of ≥99.9% at a mass ratio of 40:27:10:18 at 0.04MPa Under vacuum conditions, first raise the temperature to 950°C, keep it for 6 minutes, then raise the temperature to 1620°C, keep it for 18 minutes, then cool it down to 1030°C, keep it for 14 minutes, then raise the temperature to 1500°C, keep it for 25 minutes, and then put it at room temperature to get the master alloy , crush the master alloy into pieces and add it to a 13 mg / mL graphene oxide aqueous solution. After mixing evenly, stir to evaporate the solvent to obtain a graphene oxide modified metallic glass mixture, wherein the graphene oxide modified metallic glass mixture is oxidized The content of graphene is 0.03wt%.

[0038] (2) Add the graphene oxide-modified metallic glass mixture in batches to the vacuum heating and curing equipment, and under an inert gas atmosphere, al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com