Preparation method of alpha+alpha' phase-containing beta-phase Ti2448 biomedical alloy single crystal and single crystal

A biomedical, single crystal technology, applied in the field of biomedical alloy materials, can solve the problems such as no β-phase Ti2448 single crystal, no major breakthrough in strength and plasticity, strength and plasticity limitations, etc., and achieve convenient crystal growth process, mechanical Superior performance, low modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

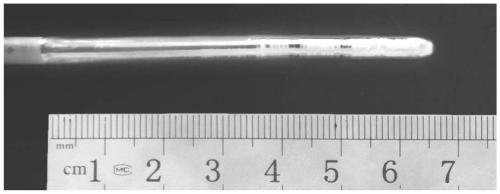

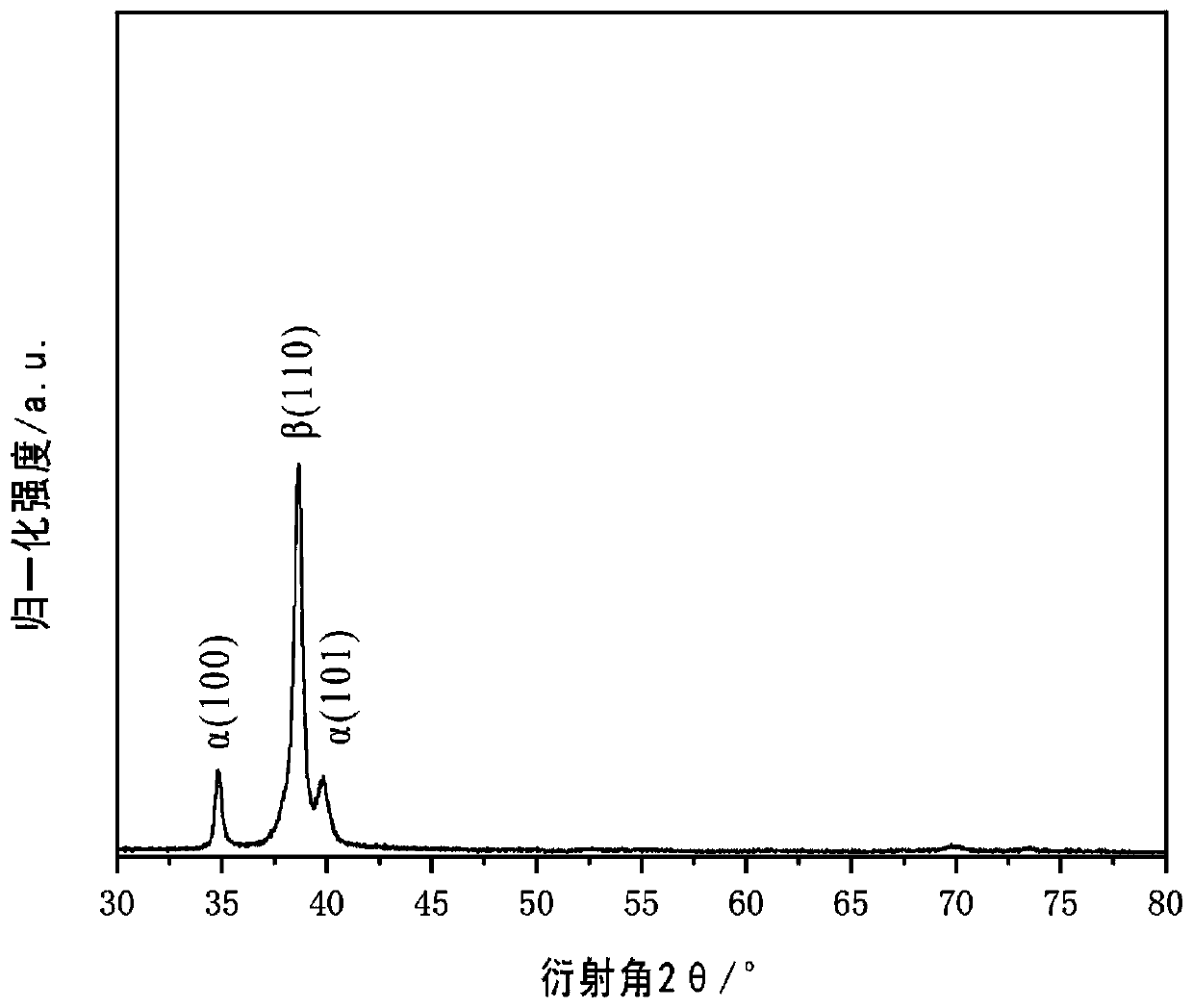

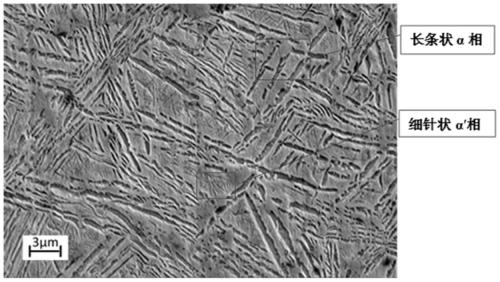

[0029] Embodiment 1: The preparation method and single crystal of a β-phase Ti2448 biomedical alloy containing α+α′ phase provided in this embodiment and the single crystal include the following steps: S1: Compress the prepared alloy powder by hydrostatic pressure Sinter the material rod into a polycrystalline rod; S2: Fix a polycrystalline rod on the upper and lower ends of the ultra-high temperature optical floating zone furnace, and the other ends of the two rods are close to each other in the heating zone; after sealing the furnace, the same Rotate the two rods simultaneously in the direction or in the opposite direction, and rapidly raise the temperature to melt the two ends, control the rotation speed to stabilize the melting, and form a stable melting zone; then move the heating zone to grow the crystal, and then turn off the power to cool down to room temperature naturally, and take out the Ti2448 single boule.

[0030] Among them, the preferred material rod is a mater...

Embodiment 2

[0034] Embodiment 2: The preparation method and single crystal of a β-phase Ti2448 biomedical alloy single crystal containing α+α′ phase provided in this embodiment are basically the same as in Embodiment 1, except that:

[0035] (1) Ingredients: Four elemental powders (≤45μm) of Ti, Nb, Zr, and Sn with a purity of 99.97% are used as raw materials, and are configured according to the mass percentage of Ti 64%, Nb 24%, Zr 4%, and Sn8%. mixed powder;

[0036] (2) Preparation of material rod: the mixed powder prepared in step (1) is immersed in alcohol in a planetary ball mill according to the parameters of ball-to-material ratio 10:1 and a rotating speed of 300r / min for 20 hours of wet ball milling, and then Put it in a vacuum drying box for 12 hours at a drying temperature of 50°C, then sieve the mixed powder (300 mesh) to obtain a pre-alloyed powder of Ti2448, put the powder into a strip-shaped balloon and seal it, pass it through static water Press the alloy powder into rods...

Embodiment 3

[0041] Embodiment 3: The preparation method and single crystal of a β-phase Ti2448 biomedical alloy single crystal containing α+α′ phase provided in this embodiment are basically the same as those in Embodiments 1 and 2, except that in the step In S1, the material rod mixing ball mill is set with a ball-to-material ratio of 8:1 and a speed of 300r / min immersed in alcohol for 24 hours; the drying time is 10 hours and the drying temperature is 60°C; the sintered material rod is Sintering in an argon atmosphere furnace, the sintering temperature is 1200°C, and the total sintering time is 13 hours; in step S2, the speed of the single crystal rod rotating in the same direction or in the opposite direction is 10 rpm, and the docking time is 10 minutes; The crystal growth rate was 15 mm / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com