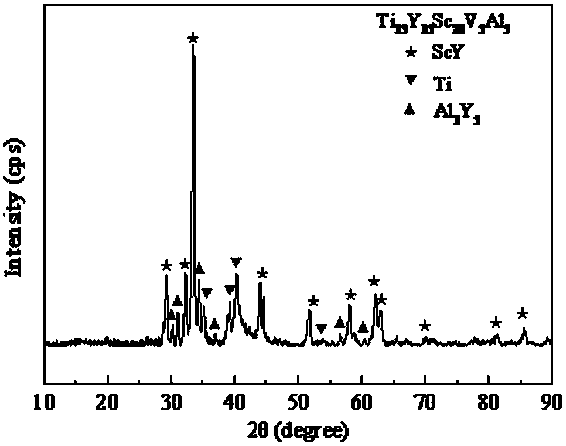

a lightweight ti 35 the y 35 sc 20 v 5 al 5 High entropy alloy and its preparation method

A ti35y35sc20v5al5, high-entropy alloy technology, applied in the field of lightweight high-entropy alloy materials, can solve the problems of high-entropy alloy solid solution diffusivity and phase transformation rate reduction, and achieve light density, high yield strength and compressive plasticity, and excellent impact toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Based on the Ti-6Al-4V titanium alloy as the design starting point, the invention adopts a high-vacuum non-consumable arc melting furnace to prepare a novel light-weight high-entropy alloy material.

[0037] The five metal elements selected are Ti, Y, Sc, V and Al, and the parameters of each element are shown in Table 1:

[0038] Table 1 Parameters of each element

[0039]

[0040] A lightweight Ti 35 Y 35 sc 20 V 5 Al 5 The preparation method of high entropy alloy comprises the steps:

[0041] The first step is to prepare raw materials. The alloy smelting raw materials used are Ti, Y, Sc, V and Al elements, which are accurately weighed and proportioned according to the molar ratio for use in smelting and preparing alloys;

[0042] The second step is the purification of pure metals. Ti, Y, Sc, V and Al are used as raw materials for alloy preparation to purify metal surface oxides;

[0043] The third step is to use a high-vacuum arc melting furnace to melt the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strain rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com