Amorphous composite material with oxygen-modulated phase transition and preparation method thereof

A technology of amorphous composite materials and composite materials, which is applied in the field of oxygen-modulated phase transition amorphous composite materials and its preparation, can solve the problems that limit the development and application of amorphous composite materials, and achieve the suppression of rapid expansion, large compression plasticity, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

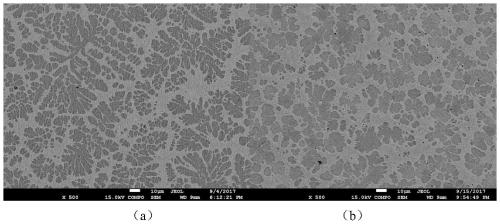

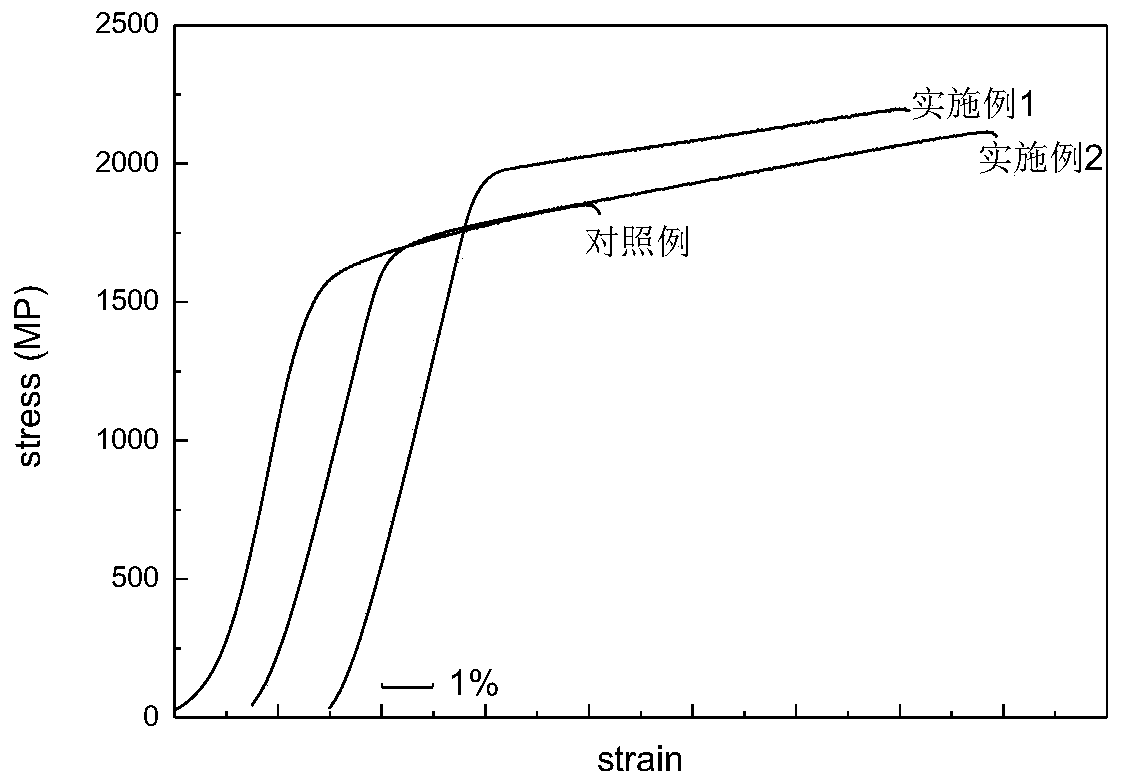

Embodiment 1

[0025] Preparation of TiZr-based amorphous composite material with O content of 6 at.%:

[0026] The first step: Weigh the pure metal raw material and CuO (purity greater than 99.9%) according to the atomic percentage of No. 1 in Table 1, wherein O is added in the form of CuO, Cu is added in the form of CuO and pure metal Cu, and the remaining elements are added in the form of pure metal , weighing accuracy is 0.001g;

[0027] The second step: smelting in a high-vacuum non-consumable electric arc furnace to obtain an 80g master alloy ingot;

[0028] Step 3: Take 25g of the master alloy and cast it into a copper mold to obtain a rod-shaped sample with a diameter of 8mm.

Embodiment 2

[0030] The difference between this example and Example 1 is that its O content is different, and the O content of the prepared composite material is 1 at.%; O is represented by ZrO 2 Form added, Zr as ZrO 2 And pure metal Zr form added.

[0031] The first step: take the pure metal raw material and ZrO according to the atomic percentage of No. 2 in Table 1 2 (purity greater than 99.9%), weighing accuracy is 0.001g;

[0032] Second step: same as embodiment 1;

[0033] The third step: same as embodiment 1.

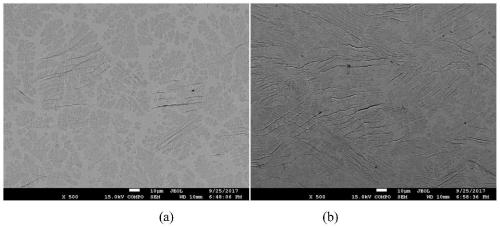

Embodiment 3

[0035] The difference between this example and Example 1 is that its O content is different, and the O content of the prepared composite material is 5 at.%; O is represented by TiO 2 Form added, Ti as TiO 2 And pure metal Ti added.

[0036] The first step: Weigh the pure metal raw material and TiO according to the atomic percentage of No. 3 in Table 1 2 (purity greater than 99.9%), weighing accuracy is 0.001g;

[0037] Second step: same as embodiment 1;

[0038] The third step: same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com