Ti-based amorphous alloy with super-large amorphous forming ability and preparation method thereof

An amorphous alloy and amorphous technology, applied in the field of amorphous alloy materials, can solve the problems of insufficient formation ability of Ti-based amorphous alloys, and achieve the effect of improving the ability of amorphous formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation (Ti 41 Zr 25 be 26 Ni 8 ) 100-x Cu x (x=2, 4, 6, 8, 10, 12 at.%) bulk amorphous alloys.

[0024] The first step is to select high-purity titanium block (99.99% purity), zirconium rod (99.7% purity), beryllium block (99.9% purity), nickel particle (99.99% purity), iron block (99.99% purity ) or a copper block (purity is 99.999%), after polishing the oxide skin on the surface of the above-mentioned metal raw material, carry out ultrasonic cleaning with acetone. According to alloy composition (Ti 41 Zr 25 be 26 Ni 8 ) 100- x Cu x Atomic percentages (x=2, 4, 6, 8, 10, 12 at.%) were converted into mass percentages, and the above alloy raw materials were measured and prepared using a balance with an accuracy of 0.0001 g.

[0025] In the second step, after mixing the above-mentioned alloy raw materials, they were respectively placed in the electric arc furnace, and the chamber was evacuated to 1×10 - 3 After Pa, the high-purity argon gas is introduce...

Embodiment 2

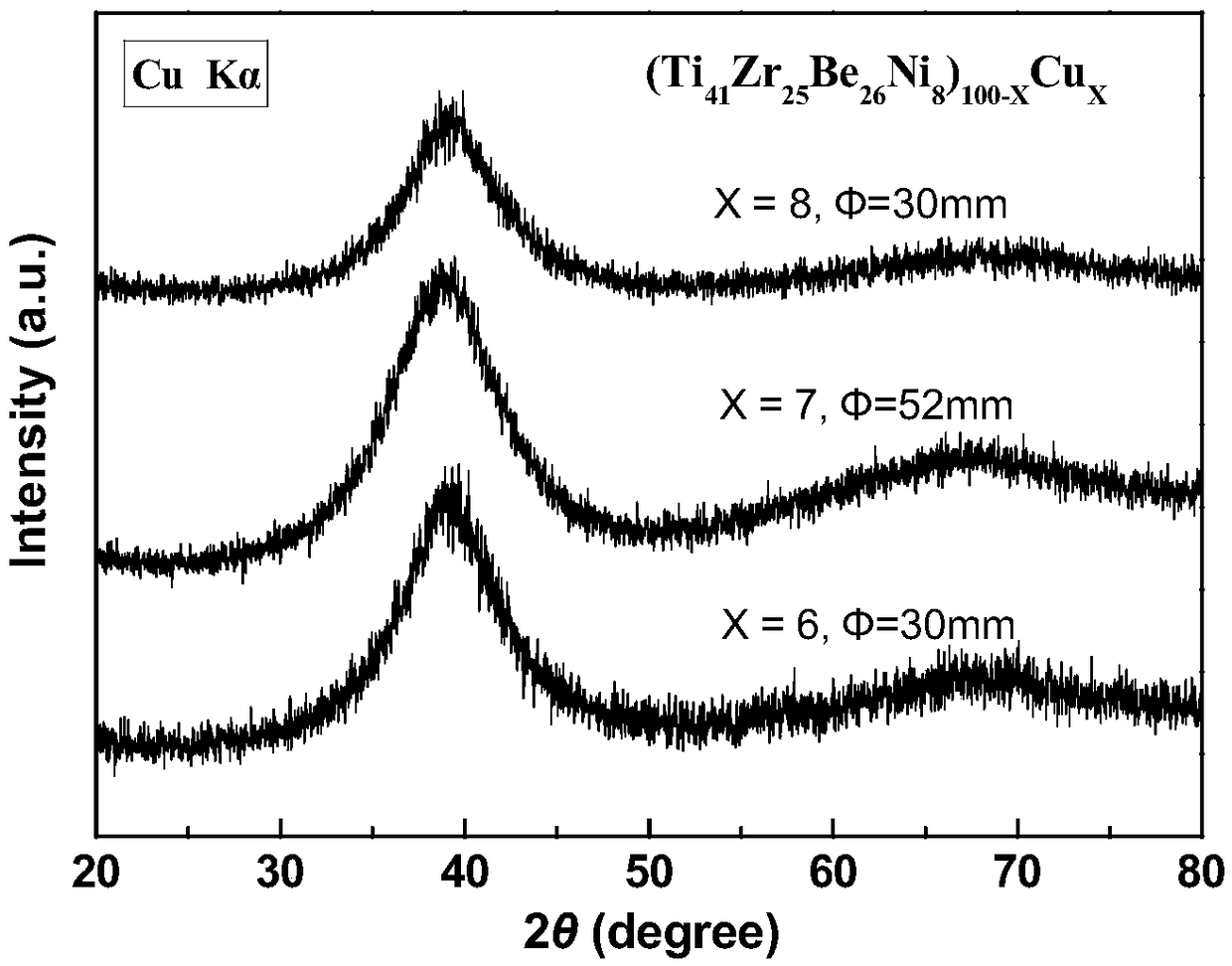

[0029] Preparation of large size (Ti 41 Zr 25 be 26 Ni 8 ) 100-x Cu x (x=6, 7, 8 at.%) bulk amorphous alloys.

[0030]In the first step, after calculating and analyzing the variation law of the liquid-solid transition free energy difference ΔG of the above-mentioned amorphous alloy with temperature, combined with the thermodynamic data analysis (Trg, ΔT, γ) of the above-mentioned amorphous alloy and the average atomic radius difference, Changes of electronegativity difference, mixing enthalpy, and mixing entropy with the content of Cu elements. It is found that when 6≤Cu≤8, the alloy may have a great ability to form amorphous, and when the Cu content is 7at%, the amorphous The ability to form is maximum. Therefore, respectively designed and trial-manufactured (Ti 41 Zr 25 be 26 Ni 8 ) 94 Cu 6 , (Ti 41 Zr 25 be 26 Ni 8 ) 93 Cu 7 , (Ti 41 Zr 25 be 26 Ni 8 ) 92 Cu 8 Bulk alloy rod samples.

[0031] The second step: according to the content of each compone...

Embodiment 3

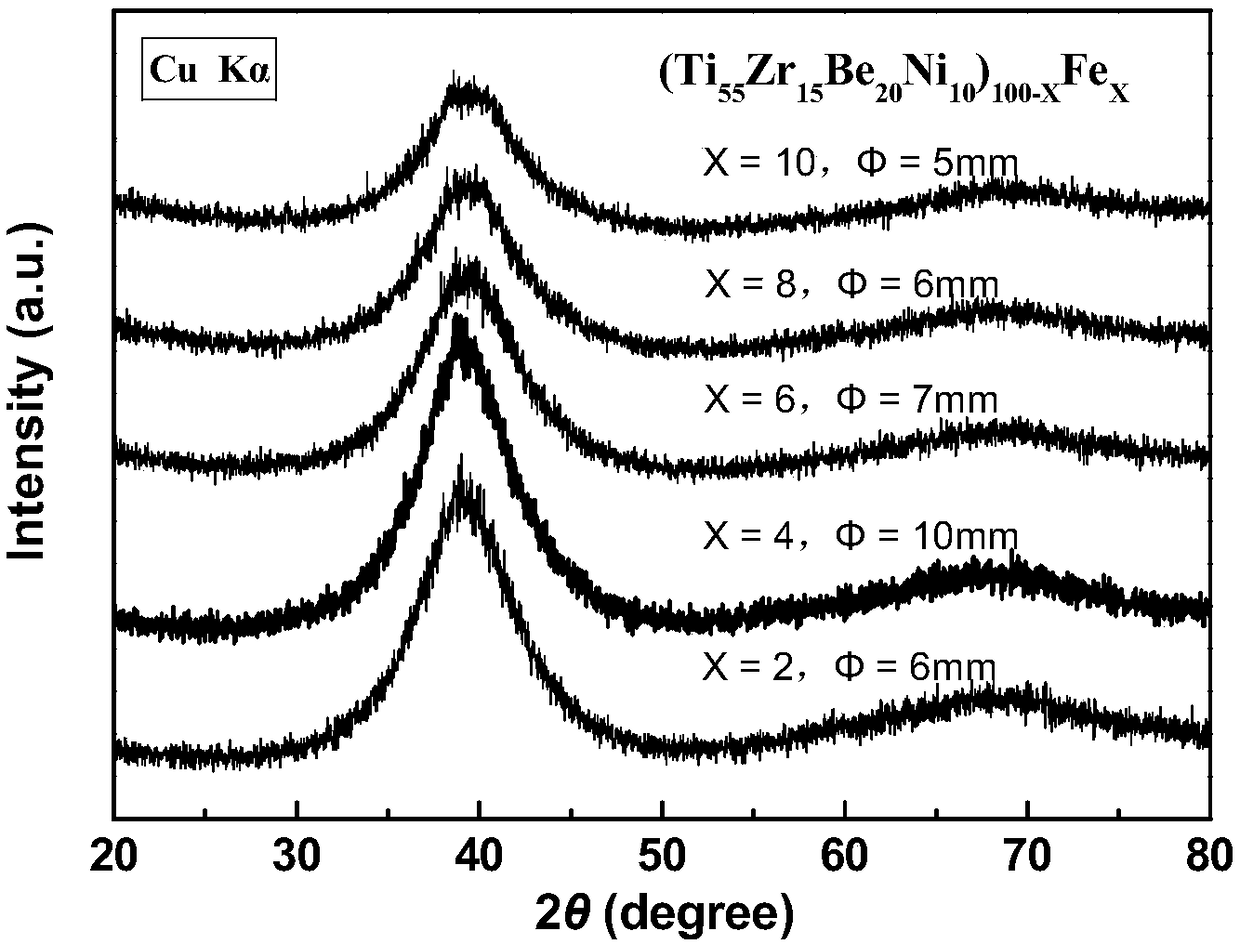

[0036] Preparation (Ti 55 Zr 15 be 20 Ni 10 ) 100-x Fe x (x=2, 4, 6, 8, 10 at.%) bulk amorphous alloy.

[0037] The first step is to select high-purity titanium block (99.99% purity), zirconium rod (99.7% purity), beryllium block (99.9% purity), nickel particle (99.99% purity), iron block (99.99% purity ) or a copper block (purity is 99.999%), after polishing the oxide skin on the surface of the above-mentioned metal raw material, carry out ultrasonic cleaning with acetone. According to the design alloy composition (Ti 55 Zr 15 be 20 Ni 10 ) 100-x Fe x (x=2, 4, 6, 8, 10 at.%) The atomic percentages of each alloy composition were converted into mass percentages, and the alloy raw materials of each composition were measured and prepared using a balance with an accuracy of 0.0001 g.

[0038] In the second step, the alloy raw materials with different components were mixed and put into the electric arc furnace respectively, and the chamber was evacuated to 1×10 -3 Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com