A kind of high-strength corrosion-resistant iron-nickel-based superalloy and its preparation method

A high-temperature alloy and iron-nickel-based technology, which is applied in the field of high-strength and corrosion-resistant iron-nickel-based superalloy and its preparation, can solve the problems of poor processing performance and achieve the effects of improving alloy processing performance, reducing raw material costs, and excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

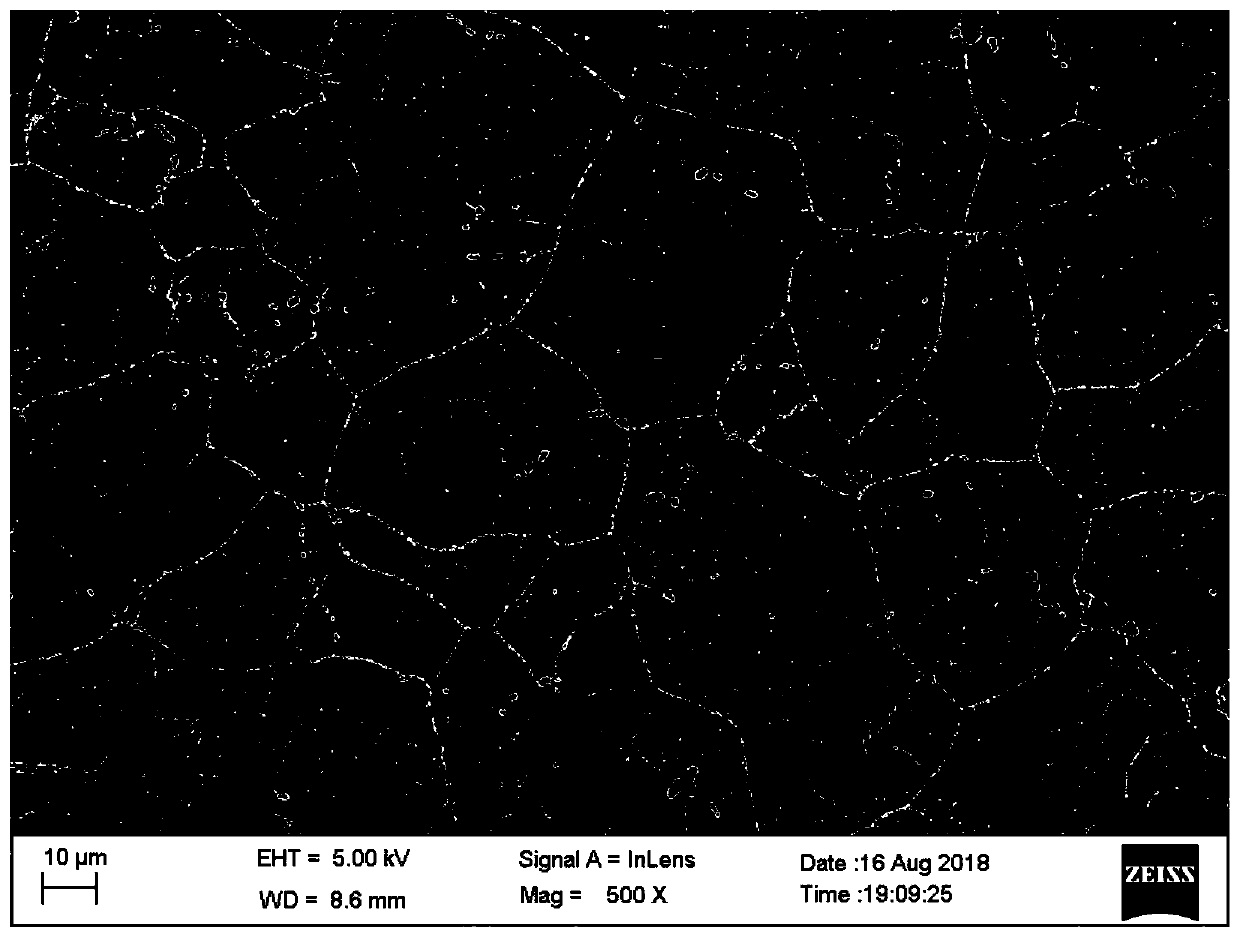

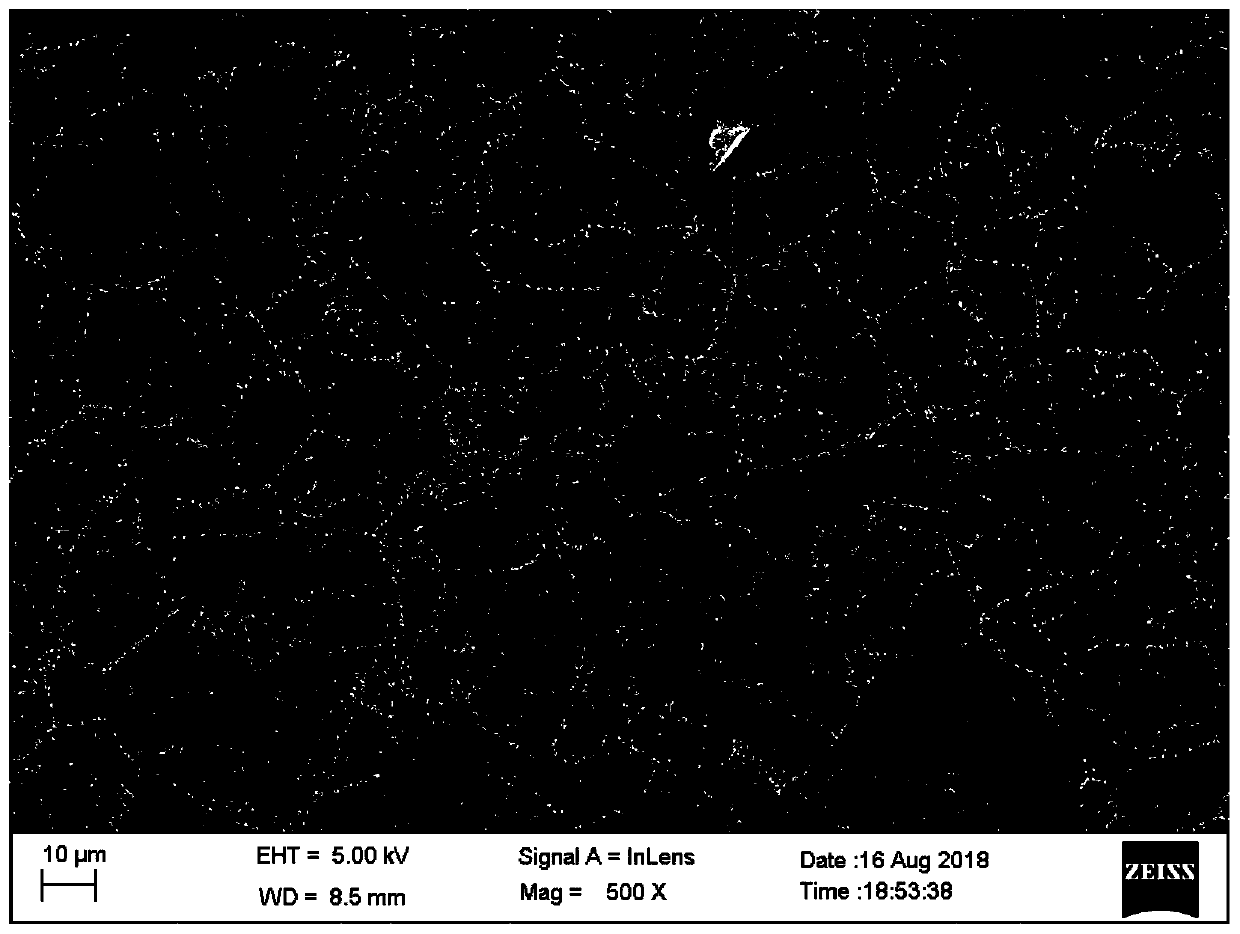

Image

Examples

Embodiment 1

[0031] The high-strength and corrosion-resistant iron-nickel-based superalloy of this embodiment includes: Cr: 15%, Ti: 0.7%, Al: 3.0%, Si: 0.5%, Mn: 0.5%, C: 0.1%, Fe : 45%, the balance is Ni;

[0032] The preparation method of the present embodiment comprises the following steps:

[0033] 1) Raw material preparation: the composition includes by mass percentage: Cr: 15%, Ti: 0.7%, Al: 3.0%, Si: 0.5%, Mn: 0.5%, C: 0.1%, Fe: 45%, and the balance is Ni;

[0034] 2) Melting step: place the ceramic crucible and prepared raw materials in a vacuum melting furnace at the same time, and use a vacuum induction furnace at a vacuum degree not higher than 1.0×10 -4 Under MPa, the prepared alloy is smelted into alloy mother liquor, and when the alloy mother liquor is solidified, an electric arc is used to preheat the ceramic crucible at low power. After the alloy is completely solidified into an ingot, it is moved to a preheated ceramic crucible to prevent the alloy ingot from contactin...

Embodiment 2

[0040]The high-strength and corrosion-resistant iron-nickel-based superalloy of this embodiment comprises: Cr: 15%, Ti: 0.7%, Al: 3.0%, Si: 0.5%, Mn: 0.5%, Cu: 3.0%, C : 0.1%, Fe: 45%, the balance is Ni;

[0041] The preparation method of the present embodiment comprises the following steps:

[0042] 1) Raw material preparation: The ingredients include by mass percentage: Cr: 15%, Ti: 0.7%, Al: 3.0%, Si: 0.5%, Mn: 0.5%, Cu: 3.0%, C: 0.1%, Fe: 45% %, the balance is Ni;

[0043] 2) Melting step: place the ceramic crucible and prepared raw materials in a vacuum melting furnace at the same time, and use a vacuum induction furnace at a vacuum degree not higher than 1.0×10 -4 Under MPa, the prepared alloy is smelted into alloy mother liquor, and when the alloy mother liquor is solidified, an electric arc is used to preheat the ceramic crucible at low power. After the alloy is completely solidified into an ingot, it is moved to a preheated ceramic crucible to prevent the alloy ing...

Embodiment 3

[0049] The high-strength and corrosion-resistant iron-nickel-based superalloy of this embodiment includes: Cr: 15%, Ti: 0.7%, Al: 3.0%, W: 1.0%, Si: 0.5%, Mn: 0.5%, C : 0.1%, Fe: 45%, the balance is Ni;

[0050] The preparation method of the present embodiment comprises the following steps:

[0051] 1) Raw material preparation: The ingredients include by mass percentage: Cr: 15%, Ti: 0.7%, Al: 3.0%, W: 1.0%, Si: 0.5%, Mn: 0.5%, C: 0.1%, Fe: 45% %, the balance is Ni;

[0052] 2) Melting step: place the ceramic crucible and prepared raw materials in a vacuum melting furnace at the same time, and use a vacuum induction furnace at a vacuum degree not higher than 1.0×10 -4 Under MPa, the prepared alloy is smelted into alloy mother liquor, and when the alloy mother liquor is solidified, an electric arc is used to preheat the ceramic crucible at low power. After the alloy is completely solidified into an ingot, it is moved to a preheated ceramic crucible to prevent the alloy ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com