A kind of titanium silicon molecular sieve and its synthesis method and application and a kind of method of phenol hydroxylation

A technology of titanium-silicon molecular sieve and phenol hydroxylation, which is applied in the application field of phenol hydroxylation and titanium-silicon molecular sieve in phenol hydroxylation. Effects of environmental pollution, uniform particle size, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

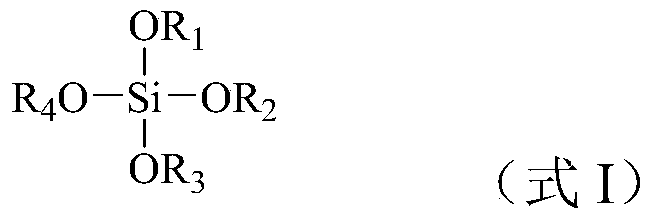

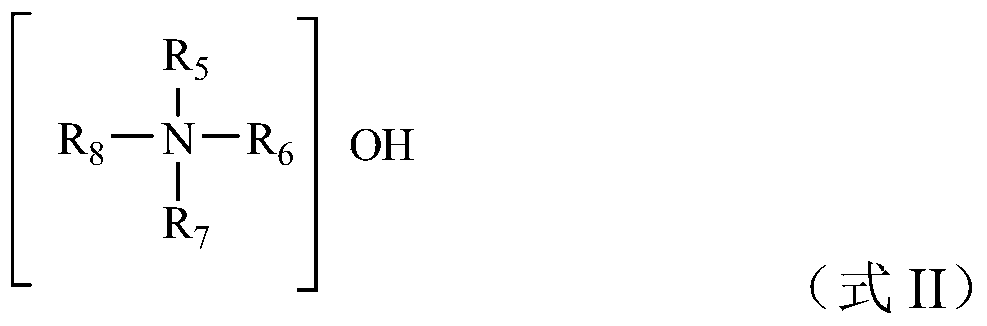

[0018] As previously mentioned, the present invention provides a kind of synthetic method of titanium silicon molecular sieve, this method comprises:

[0019] (1) Hydrolyzing the organosilicon source, the titanium source and the basic template to obtain a mixture A, and performing the first crystallization of the mixture A;

[0020] (2) Mix the material after the first crystallization with the original powder of titanium-silicon molecular sieve to obtain mixture B, and carry out the second crystallization of the mixture B, wherein, the consumption of the original powder of titanium-silicon molecular sieve makes the solid content of mixture B be 30 -80% by weight.

[0021] According to the synthetic method of the present invention, the solid content principle refers to the percentage composition that the quality of the solid matter in the reactor accounts for the total mass of the material in the reactor, and generally adopts the total weight of the total material in the reacto...

Embodiment 1

[0084] The titanium-silicon molecular sieve was prepared according to the method of Comparative Example 1, except that the crystallization conditions were different and the titanium-silicon molecular sieve was added after crystallization. The specific process is as follows:

[0085] At room temperature (20°C), mix 22.5 grams of tetraethyl orthosilicate with 7.0 grams of tetrapropylammonium hydroxide, add 59.8 grams of distilled water, stir and mix, then hydrolyze at normal pressure and 60°C for 1.0 hour to obtain ortho To the hydrolysis solution of tetraethyl silicate, slowly add a solution consisting of 1.1 g of tetrabutyl titanate and 5.0 g of anhydrous isopropanol under vigorous stirring, and stir the resulting mixture at 75°C for 3 hours to obtain a clear Transparent colloid (the hydrolysis rate of silicone source is 100%). Put this colloid into a stainless steel sealed reaction kettle, and place it at a constant temperature at 110° C. for 3 days to obtain a mixture of cr...

Embodiment 2

[0091] At a temperature of 20° C., an aqueous solution of tetrapropylammonium hydroxide with a concentration of 10% by weight was first mixed with tetrabutyl titanate, and then tetraethyl orthosilicate was added to form a mixture. SiO 2 Tetraethyl orthosilicate in terms of TiO 2 Tetrabutyl titanate in terms of NH 3 The calculated molar ratio of tetrapropylammonium hydroxide to water is 100:5:10:800. The resulting mixture was stirred at 75° C. for 3 hours to obtain a clear transparent colloid (the hydrolysis rate of the silicone source was 100%). Put this colloid into a stainless steel sealed reaction kettle, and place it at a constant temperature at 120° C. for 3 days to obtain a mixture of crystallized products. After the pressure is released, add titanium-silicon molecular sieve powder (B1) to a solid content of 60% by weight, and then the slurry The material was crystallized in a closed reactor at a temperature of 170°C and autogenous pressure for 12 hours, and the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com