Method and system for improving compression plasticity of amorphous alloy

A technology of amorphous alloys and plasticity, which is applied in the system field of improving the compression plasticity of amorphous alloys, can solve problems such as complex processes, and achieve the effect of simple, large compression plasticity and improved plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

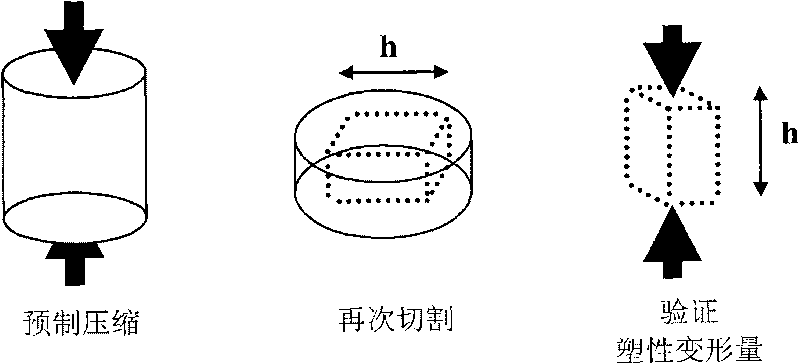

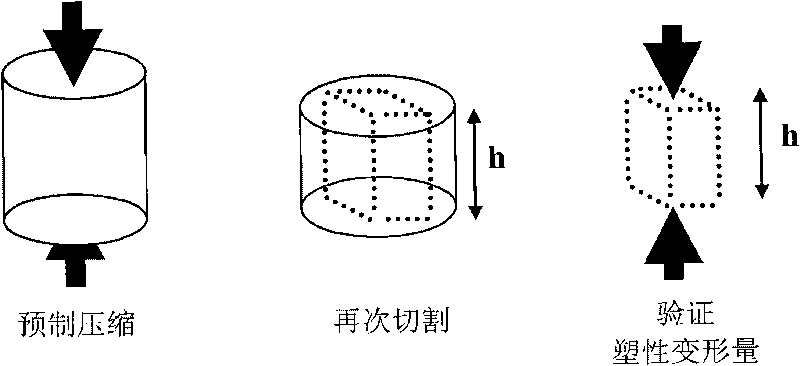

[0017] see figure 1 , figure 1 It is a flowchart of the steps of the method for improving the compressive plasticity of the amorphous alloy of the present invention.

[0018] In step S102, cutting the amorphous alloy material into a shape with an aspect ratio greater than 0 and less than 1;

[0019] In this step, the aspect ratio refers to the ratio of height to diameter for the amorphous alloy rod, and refers to the ratio of thickness to width for the amorphous alloy plate. Therefore, in this step, for the solid rod of the amorphous alloy, it should be cut into a shape with a height-to-diameter ratio greater than 0 and less than 1; for an amorphous alloy plate, it should be cut into a shape with a thickness-to-width ratio greater than 0 and less than 1.

[0020] Under standard measurement conditions (that is, the ratio of height to diameter is equal to 2.0 to 2.5), when the amorphous alloy material is compressed, the plastic deformation obtained is very small, usually no mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain | aaaaa | aaaaa |

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com