A kind of preparation method of flexible bulk metallic glass

A technology of metallic glass and bulk metal, which is applied in the field of preparation of flexible bulk metallic glass, can solve problems such as hindering the expansion of shear bands, and achieve the effect of improving compression plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

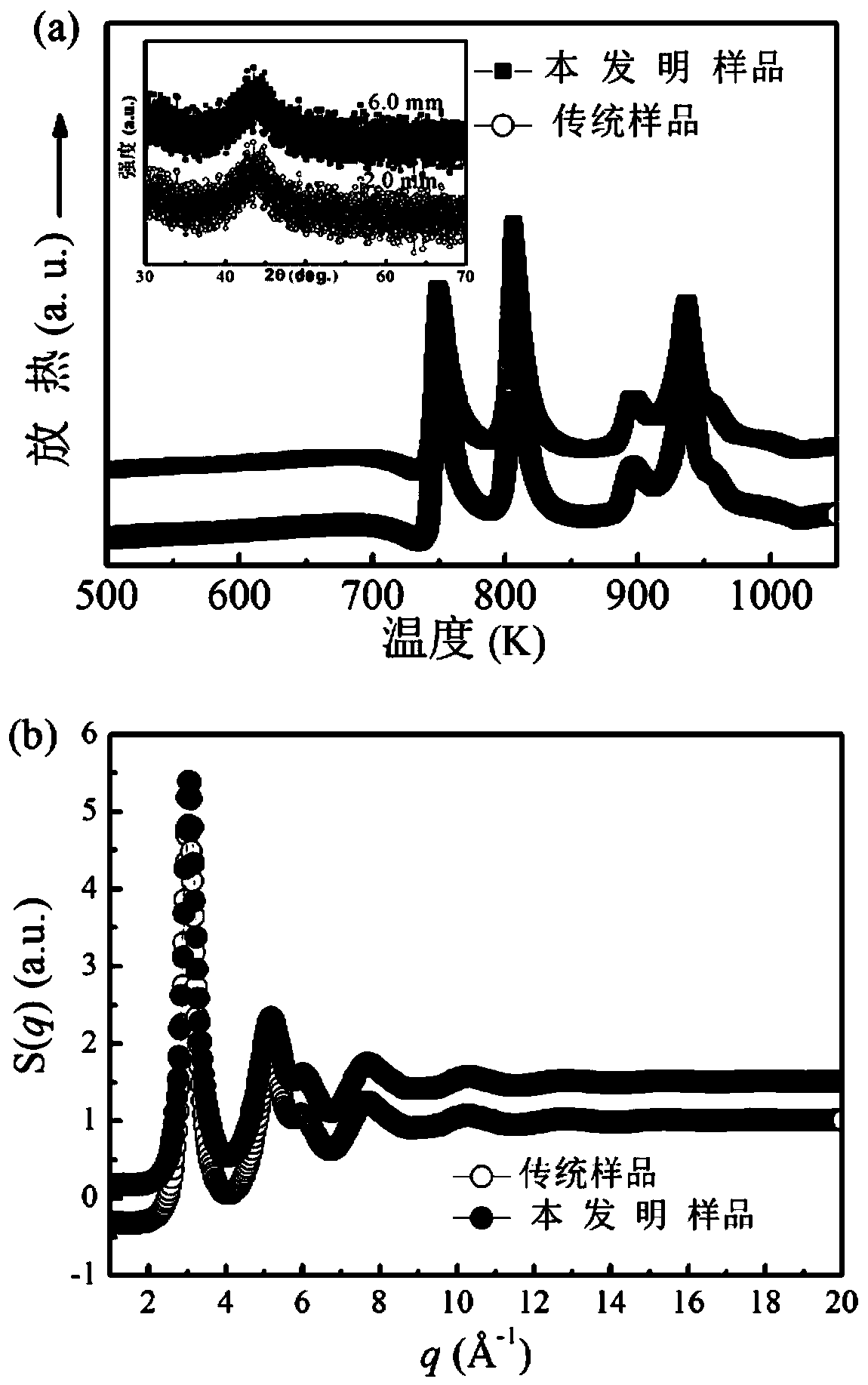

Examples

Embodiment

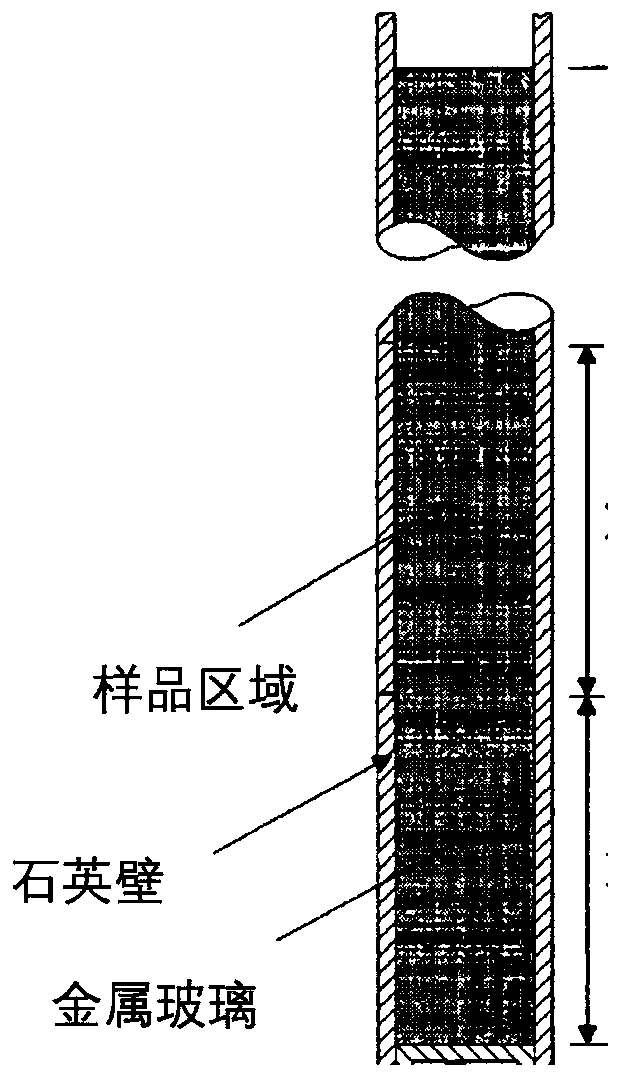

[0025] The preparation method of the flexible iron-based bulk metallic glass sample of the present embodiment comprises the following steps:

[0026] (1) Preparation of master alloy ingot: according to atomic percentage, the chemical formula of master alloy ingot is Fe 80-x (Co, Ni, Cr, Mo) x (P,B) y (C, Si) z Nb m , wherein, y+z+m=20; the raw materials for preparing the above master alloy ingot are: Fe particles (purity 99.98%), Ni particles (purity 99.7%), Fe 3 P powder (purity 99.9%), Cr powder (purity 99.9%), Co powder (purity 99.9%), Mo powder (purity 99.9%), Nb particles (purity 99.9%), B particles (purity 99.9%), Si powder (purity 99.99%) and graphite powder (purity 99.9995%). According to the set alloy composition, the precision is 10 in proportion -5 After weighing each raw material on an electronic balance of g, put each raw material into a pre-washed and dried quartz glass tube, connect the quartz glass tube to the experimental device to evacuate, and the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com