NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by W

An intermetallic compound and eutectic metal technology, which is applied in the field of W-modified NiAl-Cr(Mo) dual-phase eutectic intermetallic compounds, can solve the problems of little improvement in high temperature strength and inability to meet the requirements for use, and achieve good Comprehensive performance, improve room temperature plasticity, improve high temperature strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

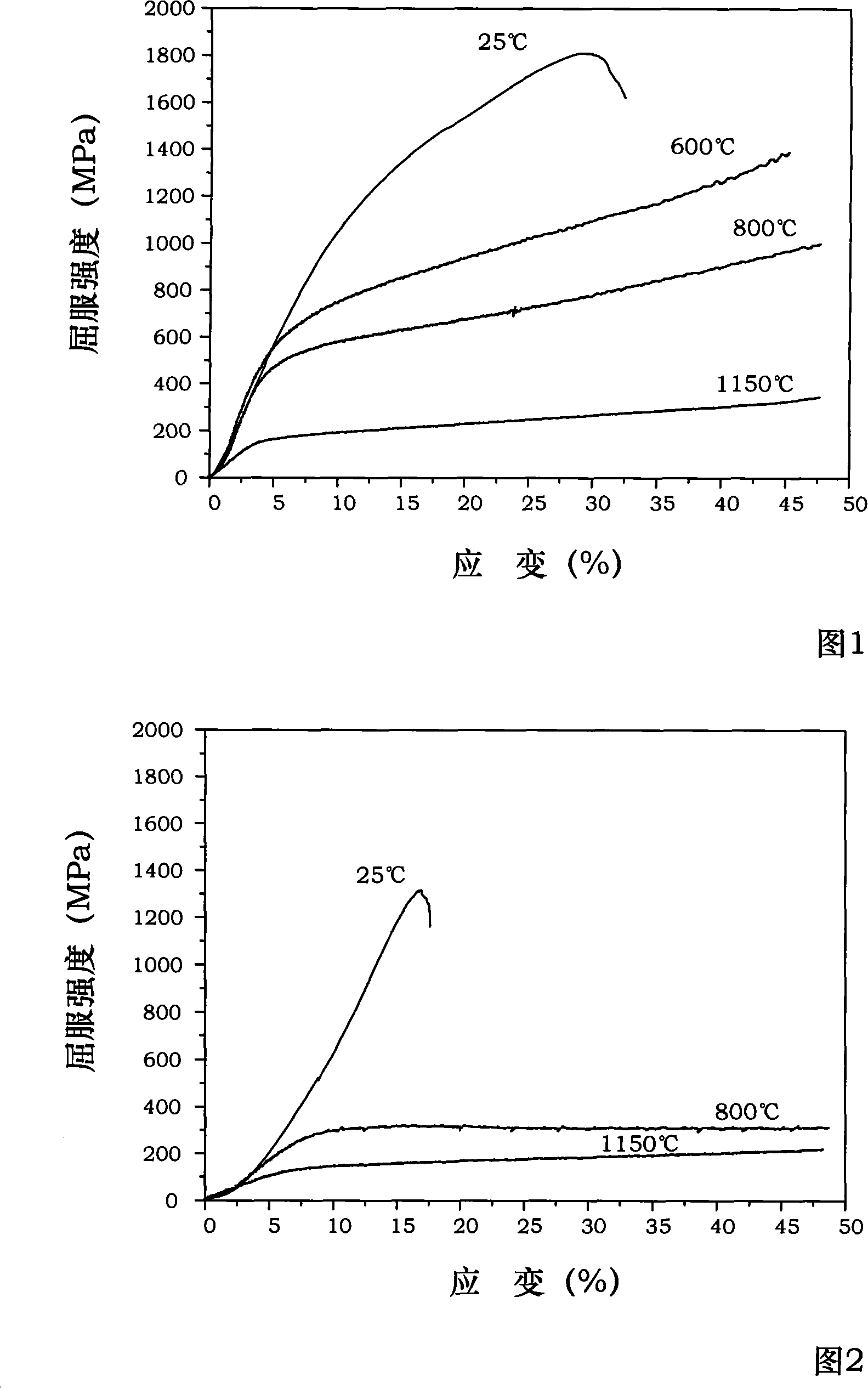

[0030] Example 1:Preparation of 33Ni-23Al-30Cr-4Mo-10W intermetallic compound

[0031] The ingredients are formulated according to the composition of 33Ni-23Al-30Cr-4Mo-10W (atomic percentage), and the purity of the raw materials is 99.999%.

[0032] Melting 33Ni-23Al-30Cr-4Mo-10W alloy ingots in a non-consumable vacuum electric arc furnace with a vacuum degree of 5×10 -3 Pa, smelting temperature 3500°C, smelting 6 times, the raw materials are smelted evenly.

[0033] The obtained intermetallic compound rod was kept at 1200° C. for 12 hours in a high-temperature heat treatment furnace, and then cooled to room temperature with the furnace.

[0034] A cylindrical sample with a diameter of 6mm and a height of 9mm and a square cylinder with a diameter of 6mm×6mm×30mm were cut from the heat-treated 33Ni-23Al-30Cr-4Mo-10W ingot by wire cutting method for mechanical performance testing.

[0035] Accurate to 10 with Model 1111 -4 The mass M of the sample is measured by an electron...

Embodiment 2

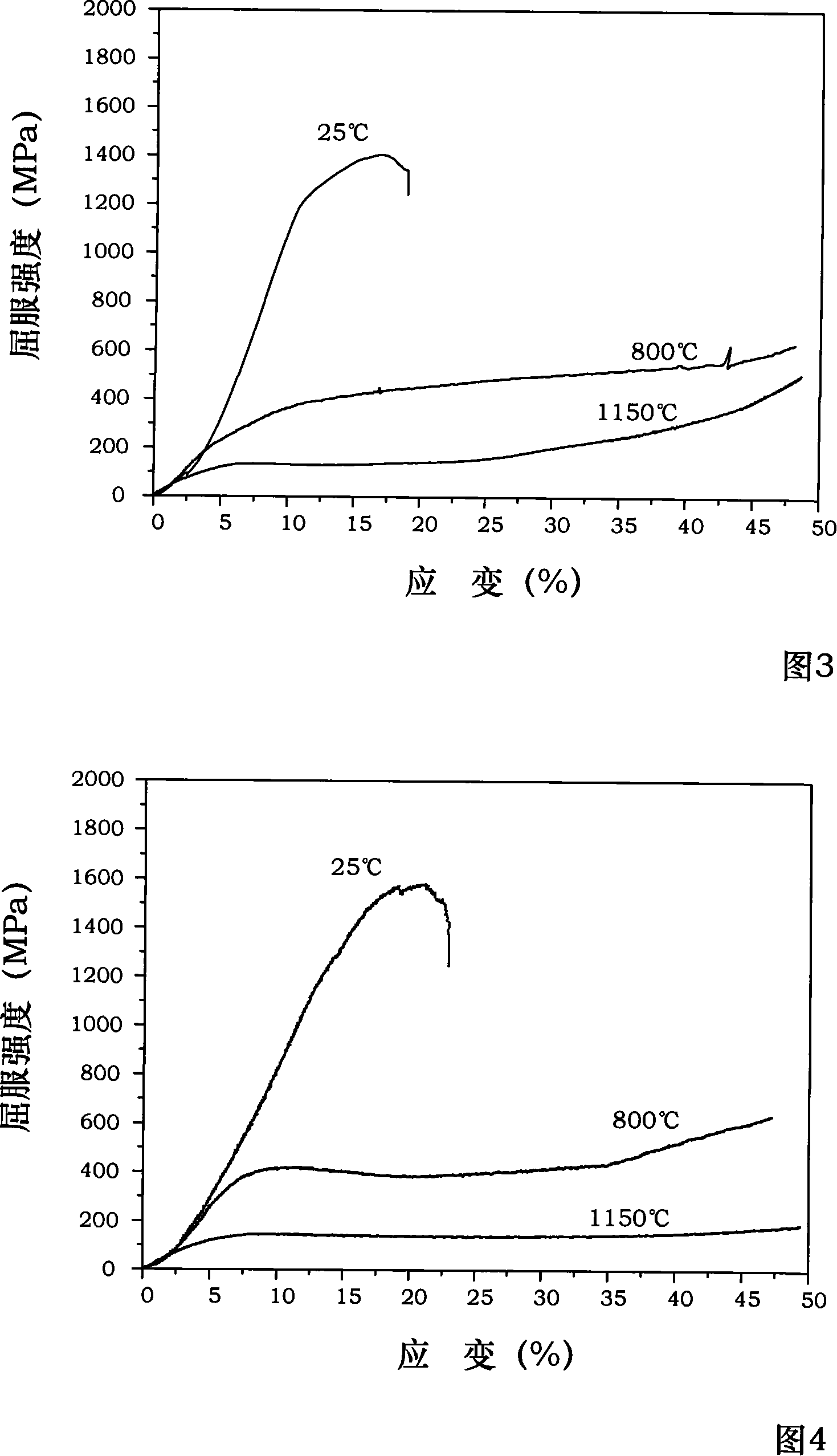

[0037] Example 2: Preparation of 33Ni-30Al-30Cr-4Mo-3W intermetallic compound

[0038] The ingredients are formulated according to the composition of 33Ni-30Al-30Cr-4Mo-3W (atomic percentage), and the purity of the raw materials is 99.999%.

[0039] Melting 33Ni-30Al-30Cr-4Mo-3W alloy ingots in a non-consumable vacuum electric arc furnace with a vacuum degree of 4×10 -3 Pa, smelting temperature 3700°C, smelting 4 times, the raw materials are smelted evenly.

[0040] The obtained intermetallic compound rod was kept at 1200° C. for 12 hours in a high-temperature heat treatment furnace, and then cooled to room temperature with the furnace.

[0041] The mechanical property testing conditions of 33Ni-30Al-30Cr-4Mo-3W intermetallic compound are the same as in Example 1, and its density is 7.02g / cm 3 See Figure 2. In the figure, the yield strength at 25°C is 1300MPa, and the compressive plasticity is greater than 15%; the yield strength at 800°C is 280MPa, and the compressive pla...

Embodiment 3

[0042] Example 3: Preparation of 33Ni-28Al-30Cr-4Mo-5W intermetallic compound

[0043] The ingredients are Ni-28Al-30Cr-4Mo-5W (atomic percentage), and the purity of the raw materials is 99.999%.

[0044] Melting 33Ni-28Al-30Cr-4Mo-5W alloy ingots in a non-consumable vacuum electric arc furnace with a vacuum degree of 3×10 -3 Pa, smelting temperature 3800°C, smelting 4 times, the raw materials are smelted evenly.

[0045] The obtained intermetallic compound rod was kept at 1200° C. for 12 hours in a high-temperature heat treatment furnace, and then cooled to room temperature with the furnace.

[0046] A cylinder sample with a diameter of 6 mm and a height of 9 mm and a square cylinder with a diameter of 6 mm × 6 mm × 30 mm were cut from the heat-treated 33Ni-28Al-30Cr-4Mo-5W ingot by wire cutting method for mechanical property testing.

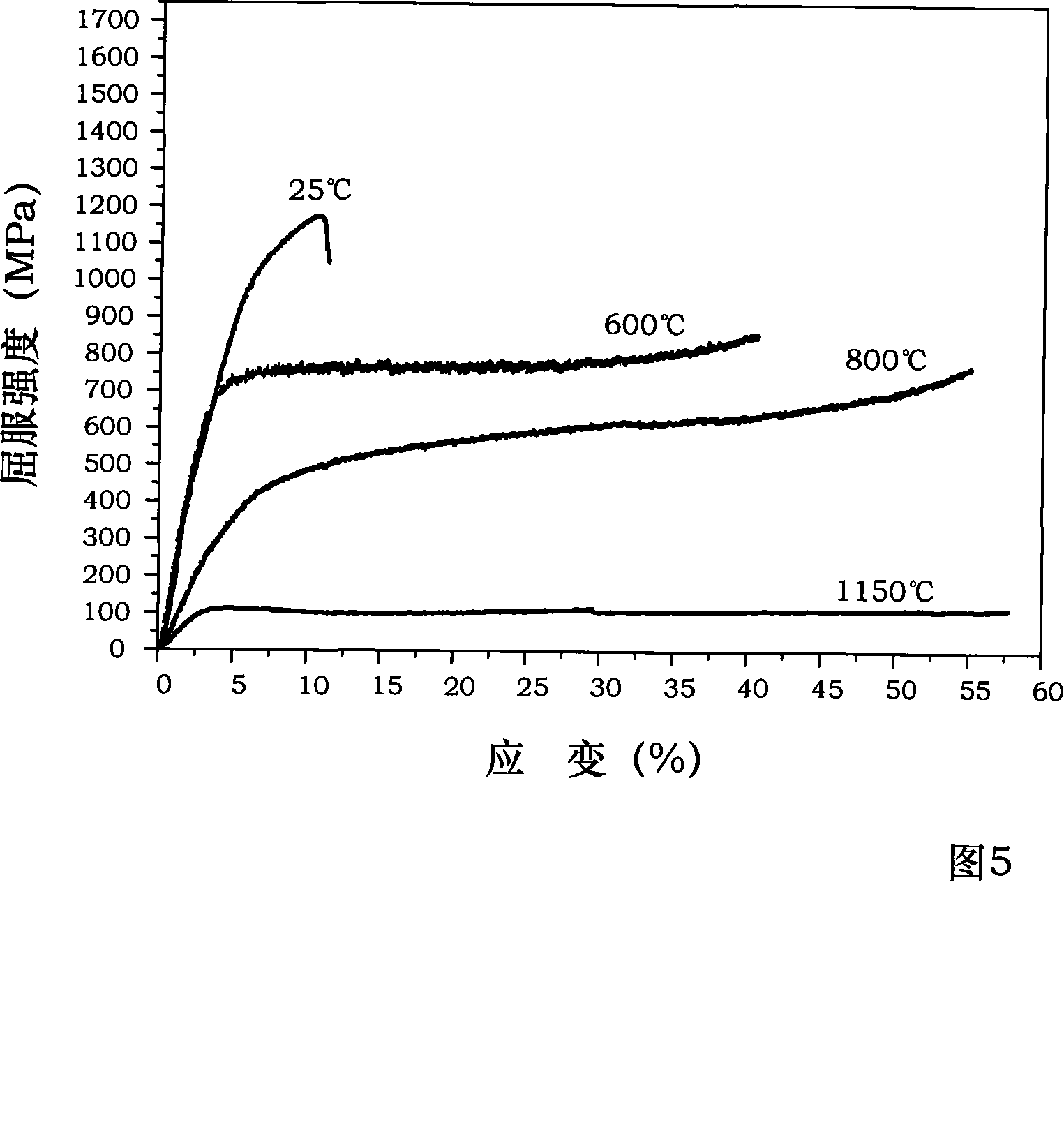

[0047] The mechanical property testing conditions of 33Ni-28Al-30Cr-4Mo-5W intermetallic compound are the same as in Example 1, and its d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com