regulate ti 48 zr 20 nb 12 cu 5 be 15 Method for Thermal Stability of Amorphous Composites

A technology of ti48zr20nb12cu5be15 and amorphous composite materials, which is applied in the field of material preparation technology, can solve the problems of difficult adjustment of shear bands, affecting the surface properties of amorphous alloys, and small space for cost reduction, so as to improve thermal stability and anti-aging ability, The effect of reducing the processing cost and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

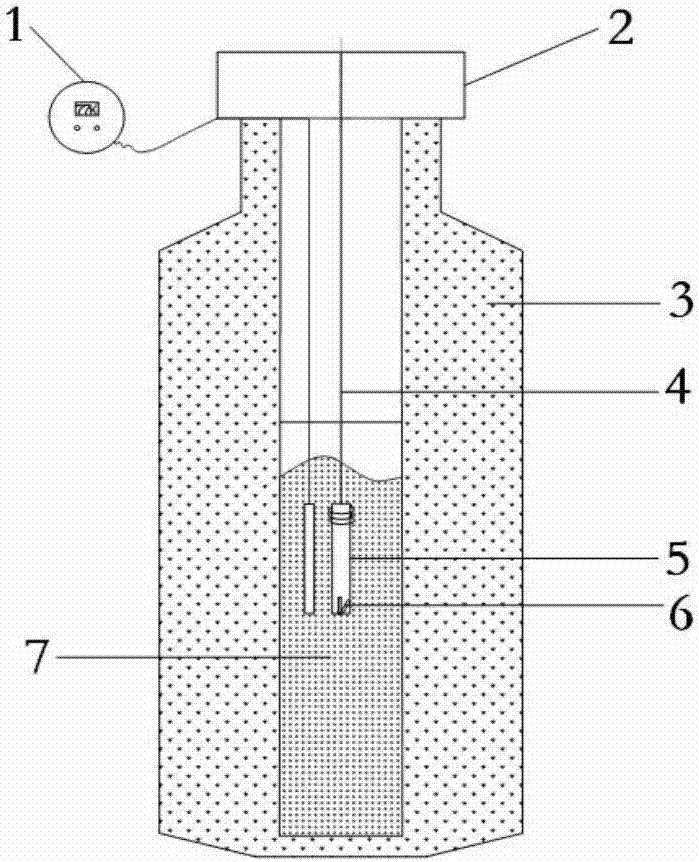

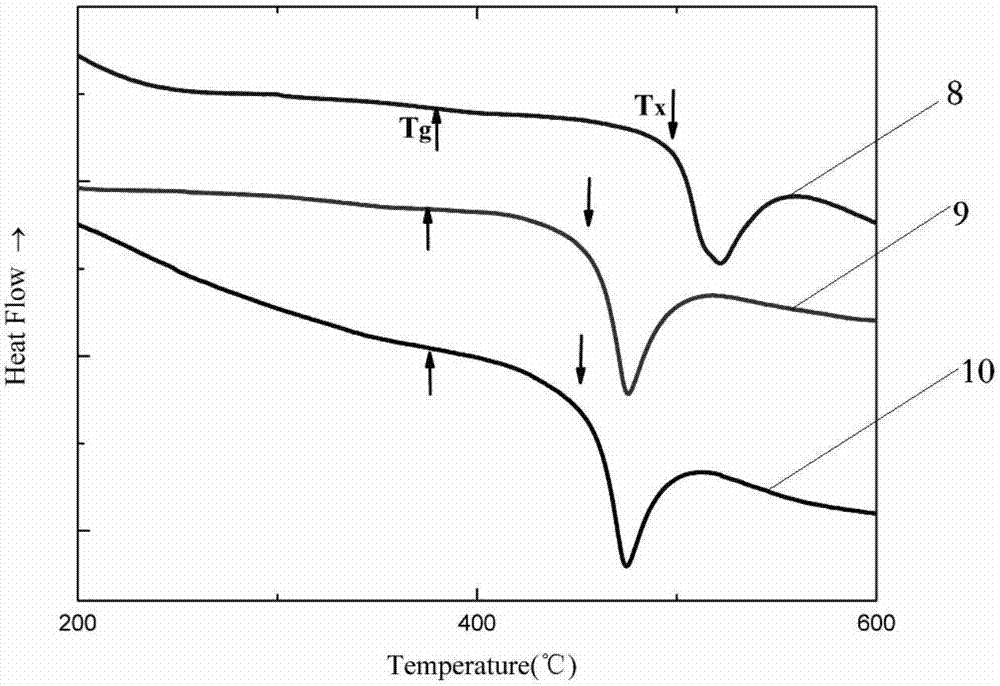

[0033] This embodiment is a kind of control Ti 48 Zr 20 Nb 12 Cu 5 be 15 The method for thermal stability of amorphous composite materials, the specific process is:

[0034] The first step is the surface treatment of raw materials. Polish Ti, Zr, Nb, Cu and Be raw materials with grinding wheels to remove surface scale, soak them in alcohol, use ultrasonic vibration to remove surface impurities such as oil stains, and obtain surface-treated Ti, Zr, Nb, Cu and Be raw materials respectively; The mentioned Ti, Zr, Nb, Cu and Be are all block.

[0035] The second step, ingredients. Convert the atomic percentages of Ti, Zr, Nb, Cu, and Be elements into mass percentages, calculate the mass of each component element according to the total mass of the alloy ingot to be obtained by smelting, and weigh the surface-treated Ti, Zr, and Nb, Cu and Be raw materials are used in the subsequent smelting process.

[0036] The third step is to prepare Ti 48 Zr 20 Nb 12 Cu 5 be 15 Amo...

Embodiment 2

[0048] The first step is the surface treatment of raw materials. The Ti, Zr, Nb, Cu and Be block raw materials are polished off the surface scale with a grinding wheel, and then soaked in alcohol to remove surface impurities such as oil and other surface impurities by ultrasonic vibration to obtain surface-treated Ti, Zr, Nb, Cu and Be blocks. raw material.

[0049] The second step, ingredients. Convert the atomic percentages of Ti, Zr, Nb, Cu, and Be elements into mass percentages, calculate the mass of each component element according to the total mass of the alloy ingot to be obtained by smelting, and weigh the surface-treated Ti, Zr, and Nb, Cu and Be block raw materials are used in the subsequent smelting process.

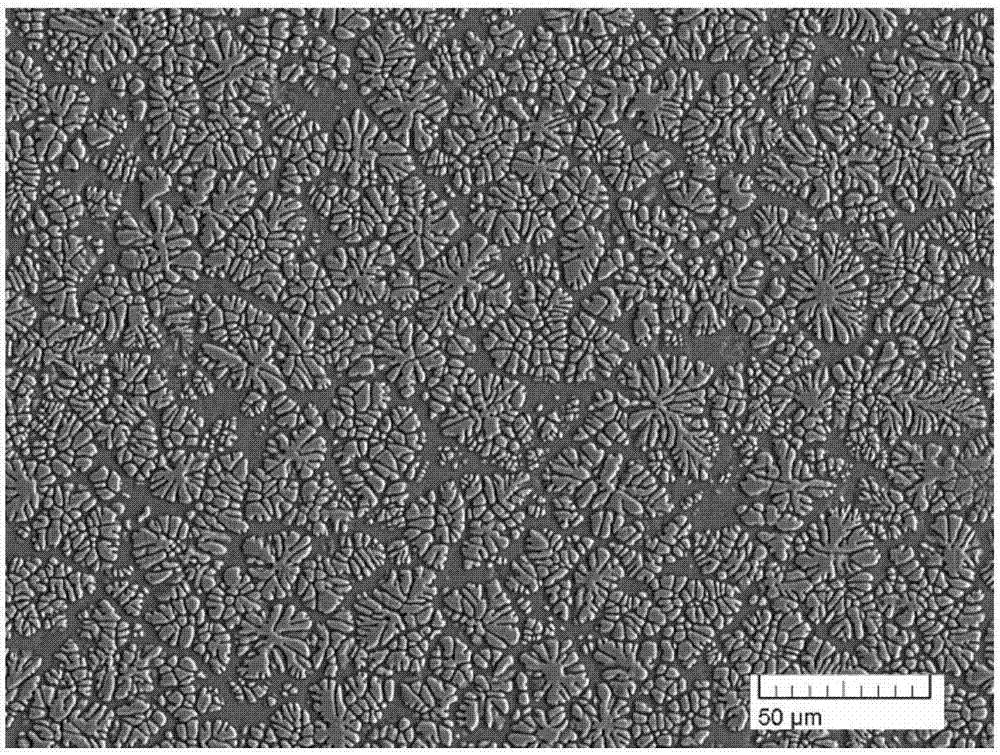

[0050] In the third step, an alloy ingot of Ti48Zr20Nb12Cu5Be15 amorphous composite material is prepared. Put the surface-treated bulk Ti, Zr, Nb, Cu and Be raw materials together into a vacuum arc melting furnace, and melt to prepare a Ti48Zr20Nb12Cu5Be15 ...

Embodiment 3

[0060] The first step is the surface treatment of raw materials. The Ti, Zr, Nb, Cu and Be block raw materials are polished off the surface scale with a grinding wheel, and then soaked in alcohol to remove surface impurities such as oil and other surface impurities by ultrasonic vibration to obtain surface-treated Ti, Zr, Nb, Cu and Be blocks. raw material.

[0061] The second step, ingredients. Convert the atomic percentages of Ti, Zr, Nb, Cu, and Be elements into mass percentages, calculate the mass of each component element according to the total mass of the alloy ingot to be obtained by smelting, and weigh the surface-treated Ti, Zr, and Nb, Cu and Be block raw materials are used in the subsequent smelting process.

[0062]In the third step, an alloy ingot of Ti48Zr20Nb12Cu5Be15 amorphous composite material is prepared. Put the surface-treated bulk Ti, Zr, Nb, Cu and Be raw materials together into a vacuum arc melting furnace, and melt to prepare a Ti48Zr20Nb12Cu5Be15 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| Compressive plasticity | aaaaa | aaaaa |

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com