A preparation method of ti2448 biomedical alloy with low Young's modulus

A Young's modulus, biomedical technology, applied in the field of biomedical alloy materials, achieves the effects of low elastic modulus, simple preparation process and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of preparation method of Ti2448 biomedical alloy with low Young's modulus provided in this embodiment, the steps are as follows:

[0028] (1) Ingredients: Ti, Nb, Zr, and Sn with a purity of 99.99% are used as raw materials, according to mass percentage Ti: 64wt.%, Nb: 24wt.%, Zr: 4wt.%, Sn: 8wt. % ratio preparation;

[0029] (2) Melting: Preparation of ingot alloy: melt the metal element mixed in the step (1) in vacuum arc melting, in order to ensure the uniformity of alloy ingot composition, turn over 6-7 times during smelting.

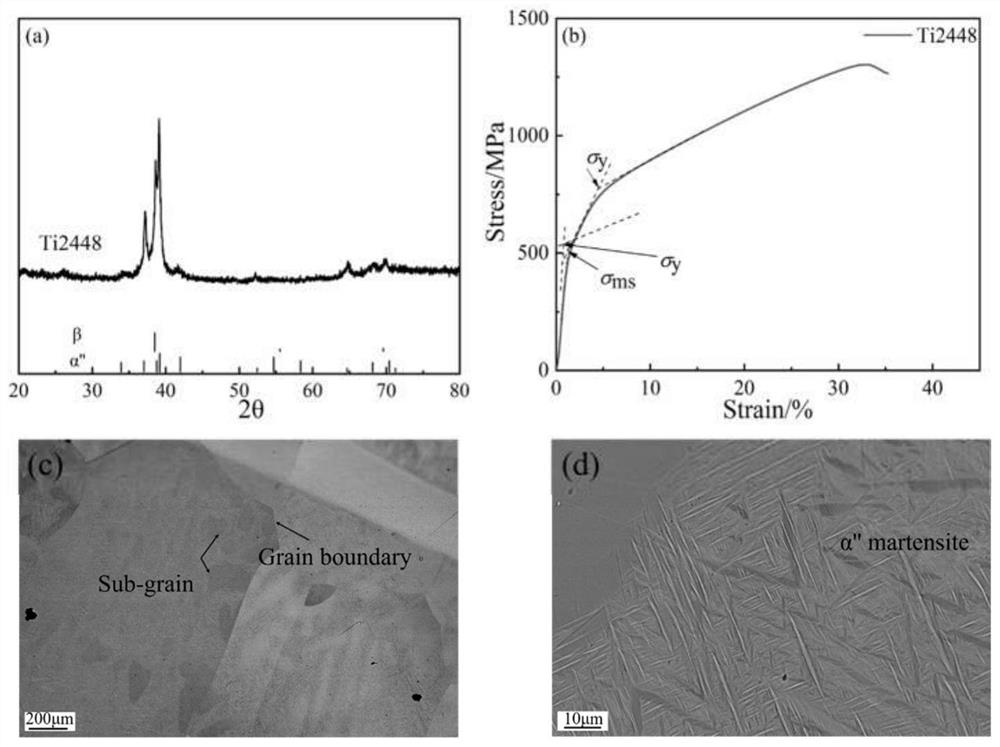

[0030] (3) As-cast alloy test: Characterize the microstructure and compressive mechanical properties of the as-cast alloy. get attached figure 1 the result of.

[0031] (4) Rolling: First, the alloy is subjected to the second rolling process parameter, that is, the alloy is hot-rolled at 850°C. When hot-rolling, the alloy is firstly kept at 850°C for 30Min, and then hot-rolled. In order to prevent the alloy from cracki...

Embodiment 2

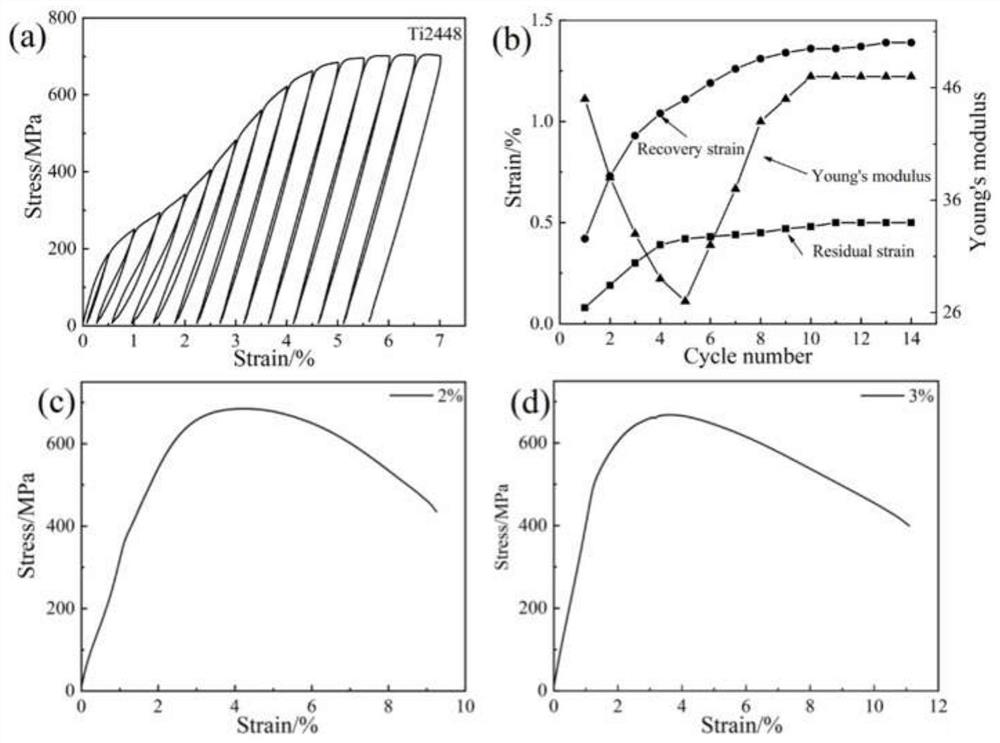

[0035] Embodiment 2: the preparation method of a kind of Ti2448 biomedical alloy with low Young's modulus provided by this embodiment, it is basically the same as embodiment 1, the difference is: in (4) step, carried out the first It is a rolling process, that is, the alloy is hot-rolled at 1000°C, and the deformation is about 85%. When hot-rolling, the alloy is first kept at 1000°C for 30 minutes, and then hot-rolled. All the alloys are returned to the furnace for 5-10 minutes. as attached Figure 4 shown.

Embodiment 3

[0036] Embodiment 3: the preparation method of a kind of Ti2448 biomedical alloy with low Young's modulus provided by this embodiment, it is basically the same as embodiment 1, the difference is: in (4) step, carried out the second It is a rolling process, that is, after hot rolling at 850°C, the deformation is 55%, and then it is cold rolled to ~1.5mm at room temperature. During hot rolling, the alloy is first kept at 850°C for 30Min, and then hot rolled. In order to prevent the alloy from cracking, After that, the alloy is returned to the furnace for 5-10 minutes before hot rolling for each pass, and then the alloy is cold-rolled for multiple passes, and the final plate thickness is 1.5mm. as attached Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com