Ti-based block amorphous alloy with great amorphous forming ability and preparation method thereof

A technology of amorphous alloy and base block, which is applied in the field of Ti-based bulk amorphous alloy and its preparation, which can solve the problems of low density and increased manufacturing cost, and achieve high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

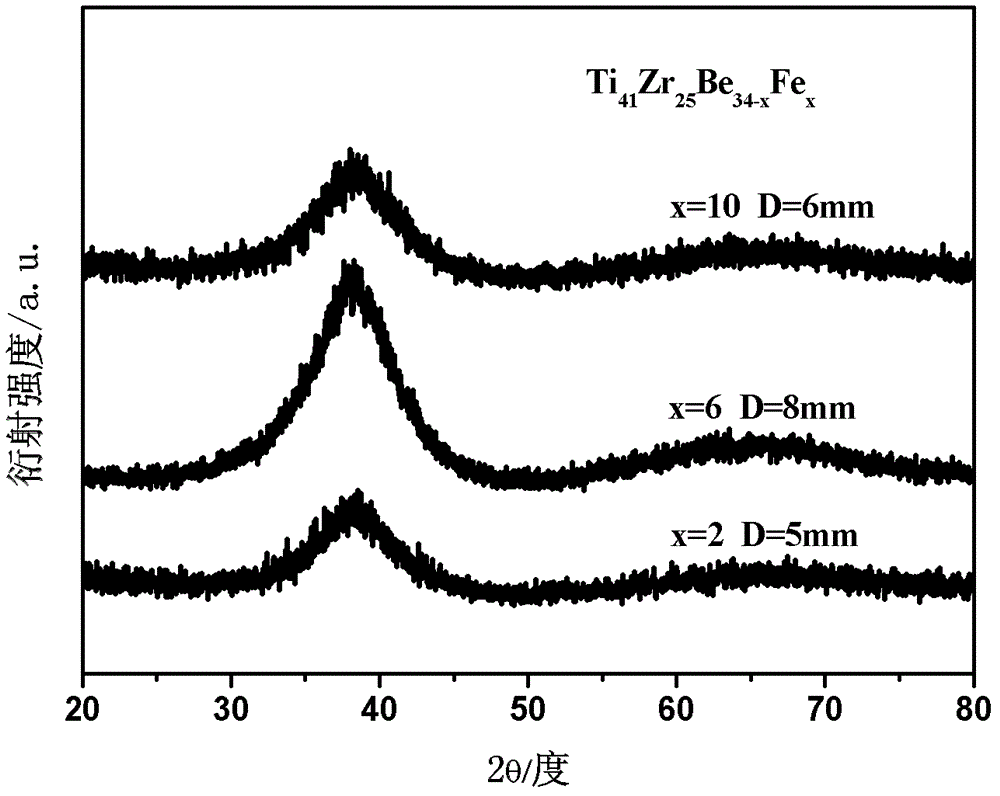

[0039] Preparation of Ti 41 Zr 25 be 32 Fe 2 bulk amorphous alloy;

[0040] In the first step, the atomic percent composition of the Ti-based bulk amorphous alloy is converted into mass percent, and the raw materials are weighed out.

[0041] The raw materials are titanium rods (purity: 99.4%), zirconium rods (purity: 99.7%), beryllium blocks (purity: 99.99%) and iron blocks (purity: 99.99%). The above materials are polished and scaled and then ultrasonically cleaned with acetone or alcohol. , the atomic percent composition of the Ti-based bulk amorphous alloy is converted into mass percent, and the alloy raw materials are prepared by weighing according to the mass percent, and the weighing tool is a balance with an accuracy of 0.0001 g.

[0042] In the second step, the raw materials are mixed and put into an electric arc furnace or an induction melting furnace to melt under vacuum or gas protection conditions and make a master alloy ingot.

[0043] Electric arc melting f...

Embodiment 2

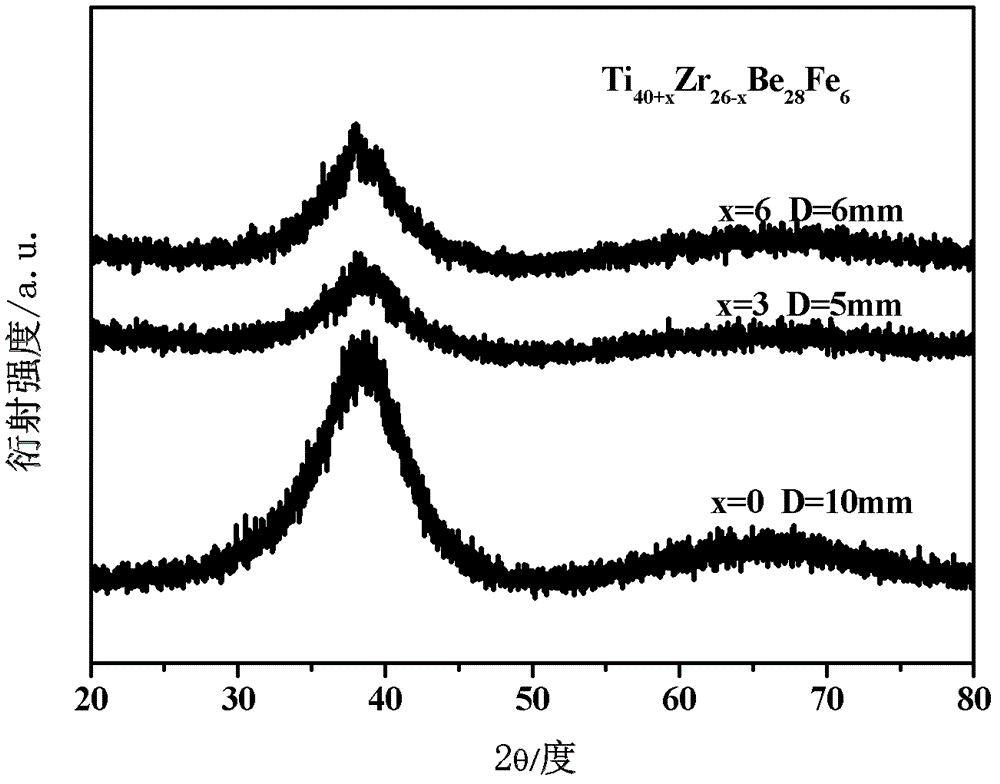

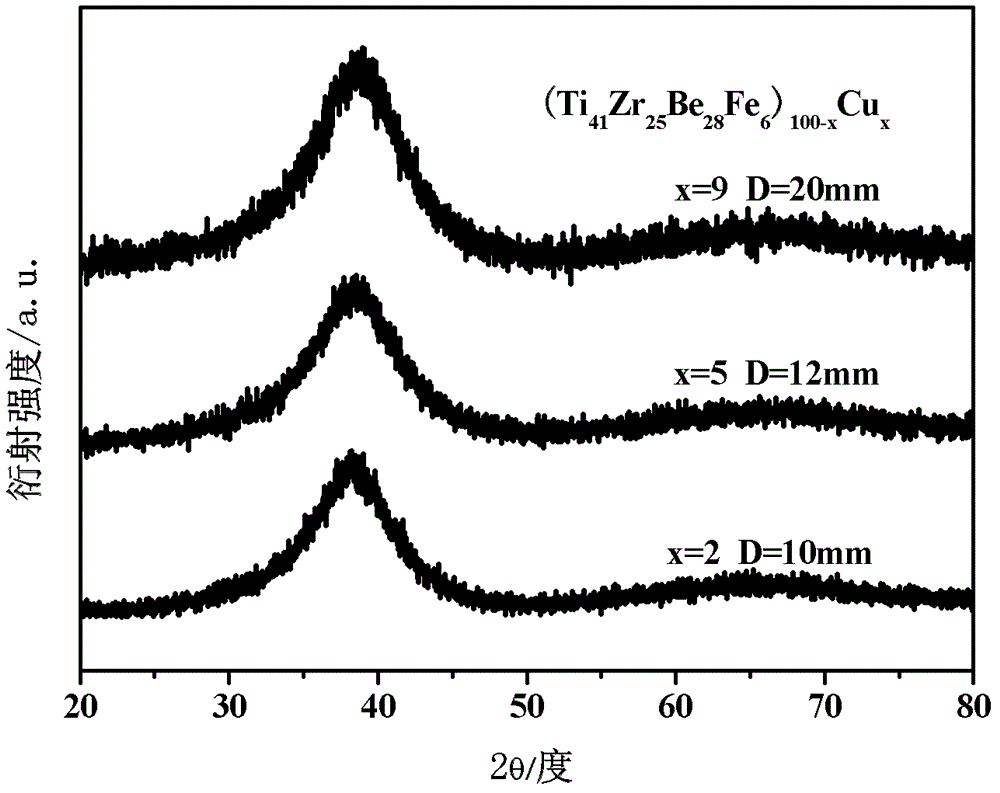

[0053] Preparation of Ti 41 Zr 25 be 28 Fe 6 bulk amorphous alloy;

[0054] In the first step, the atomic percent composition of the Ti-based bulk amorphous alloy is converted into mass percent, and the raw materials are weighed out.

[0055] The raw materials are titanium rods (purity: 99.4%), zirconium rods (purity: 99.7%), beryllium blocks (purity: 99.99%) and iron blocks (purity: 99.99%). The above materials are polished and scaled and then ultrasonically cleaned with acetone or alcohol. , the atomic percent composition of the Ti-based bulk amorphous alloy is converted into mass percent, and the alloy raw materials are prepared by weighing according to the mass percent, and the weighing tool is a balance with an accuracy of 0.0001 g.

[0056] In the second step, the raw materials are mixed and put into an electric arc furnace or an induction melting furnace to melt under vacuum or gas protection conditions and make a master alloy ingot.

[0057] Electric arc furnace s...

Embodiment 3

[0065] Preparation of Ti 41 Zr 25 be 24 Fe 10 bulk amorphous alloy;

[0066] In the first step, the atomic percent composition of the Ti-based bulk amorphous alloy is converted into mass percent, and the raw materials are weighed out.

[0067] The raw materials are titanium rods (purity: 99.4%), zirconium rods (purity: 99.7%), beryllium blocks (purity: 99.99%) and iron blocks (purity: 99.99%). The above materials are polished and scaled and then ultrasonically cleaned with acetone or alcohol. , and then weigh and prepare alloy raw materials according to mass percentage.

[0068] In the second step, the raw materials are mixed and put into an electric arc furnace or an induction melting furnace to melt under vacuum or gas protection conditions and make a master alloy ingot.

[0069] Electric arc melting furnace method: Vacuumize the electric arc furnace with mixed raw materials to 1×10 -3 Pa, arc melting is carried out under the condition of vacuum or argon protection, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com