NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Zr

A technology of intermetallic compounds and eutectic metals, which is applied in the field of Zr-modified NiAl-Cr(Mo) dual-phase eutectic intermetallic compounds, can solve the problems of little improvement in high-temperature strength and failure to meet the use requirements, and achieve improved The effect of high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of 33Ni-23Al-30Cr-4Mo-10Zr intermetallic compound

[0032] The ingredients are 33Ni-23Al-30Cr-4Mo-10Zr (atomic percentage), and the purity of the raw materials is 99.999%.

[0033] Melting 33Ni-23Al-30Cr-4Mo-10Zr alloy ingots in a non-consumable vacuum electric arc furnace with a vacuum degree of 5×10 -3 Pa, smelting temperature 3000°C, smelting 4 times, the raw materials are smelted evenly.

[0034] The obtained intermetallic compound rod was kept at 1200° C. for 12 hours in a high-temperature heat treatment furnace, and then cooled to room temperature with the furnace.

[0035] A cylinder sample with a diameter of 6mm and a height of 9mm and a square cylinder with a diameter of 6mm×6mm×30mm were cut from the heat-treated 33Ni-23Al-30Cr-4Mo-10Zr ingot by wire cutting method for mechanical performance testing.

[0036] Accurate to 10 with Model 1111 -4 The mass M of the sample is measured by an electronic balance of g with an accuracy of 10 -...

Embodiment 2

[0038] Example 2: Preparation of 33Ni-30Al-30Cr-4Mo-3Zr intermetallic compound

[0039] The ingredients are 33Ni-30Al-30Cr-4Mo-3Zr (atomic percentage), and the purity of the raw materials is 99.999%.

[0040] Melting 33Ni-30Al-30Cr-4Mo-3Zr alloy ingots in a non-consumable vacuum electric arc furnace with a vacuum degree of 3×10 -3 Pa, the melting temperature is 2700°C, smelting 6 times, and the raw materials are smelted evenly.

[0041] The obtained intermetallic compound rod was kept at 1200° C. for 12 hours in a high-temperature heat treatment furnace, and then cooled to room temperature with the furnace.

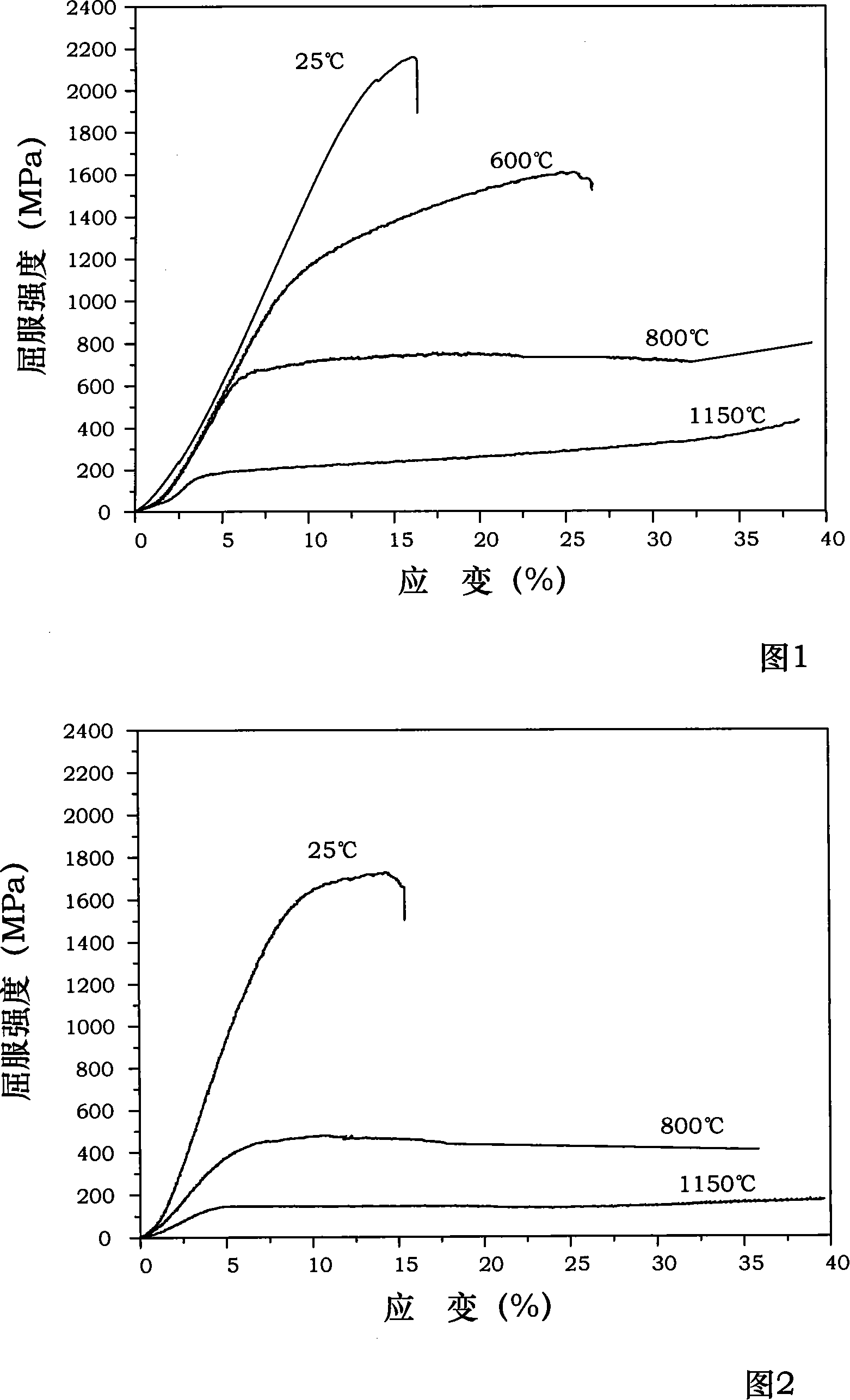

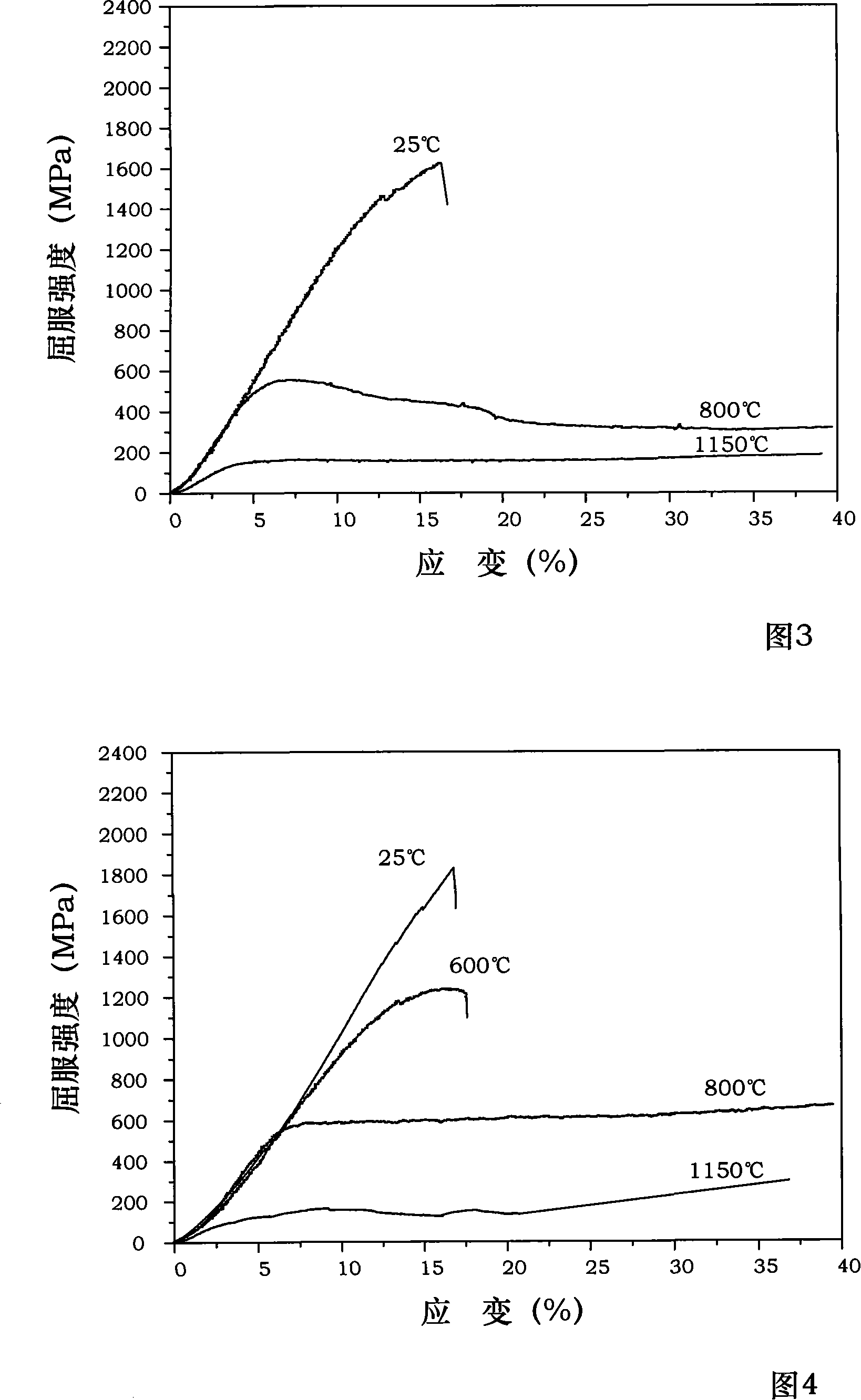

[0042] The mechanical property testing conditions of 33Ni-30Al-30Cr-4Mo-3Zr intermetallic compound are the same as in Example 1, and its density is 6.24g / cm 3 See Figure 2, in the figure, the yield strength at 25°C is 1600MPa, and the compression plasticity is greater than 15%; the yield strength at 800°C is 380MPa, and the compression plasticity is greater than 40%; ...

Embodiment 3

[0043] Example 3: Preparation of 33Ni-28Al-30Cr-4Mo-5Zr intermetallic compound

[0044] The ingredients are formulated according to the composition of 33Ni-28Al-30Cr-4Mo-5Zr (atomic percentage), and the purity of the raw materials is 99.999%.

[0045] Melting 33Ni-28Al-30Cr-4Mo-5Zr alloy ingots in a non-consumable vacuum electric arc furnace with a vacuum degree of 5×10 -3 Pa, smelting temperature 2500°C, smelting 4 times, the raw materials are smelted evenly.

[0046] The obtained intermetallic compound rod was kept at 1200° C. for 12 hours in a high-temperature heat treatment furnace, and then cooled to room temperature with the furnace.

[0047] A cylindrical sample with a diameter of 6mm and a height of 9mm and a square cylinder with a diameter of 6mm×6mm×30mm were cut from the heat-treated 33Ni-28Al-30Cr-4Mo-5Zr ingot by wire cutting method for mechanical performance testing.

[0048] Accurate to 10 with Model 1111 -4 The mass M of the sample is measured by an electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com