High-toughness low-activation FeCrVO multi-principal-element alloy and preparation method thereof

A multi-principal alloy and low-activation technology is applied in the field of high-strength, toughness and low-activation FeCrVO multi-principal alloy and its preparation, which can solve the problems of poor toughness of multi-principal alloys and achieve high thermal stability and excellent radiation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

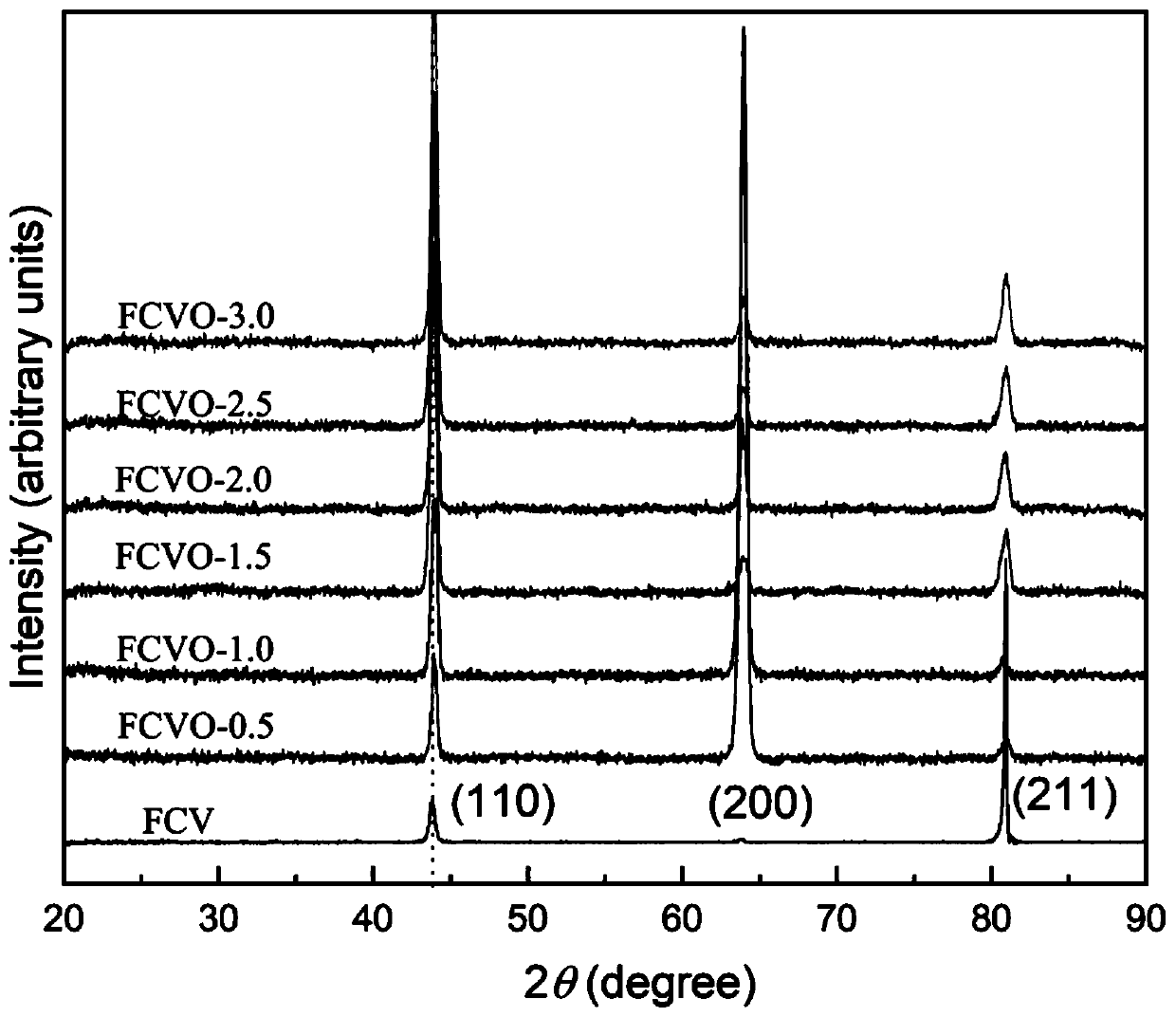

[0034] A high-strength, toughness and low-activation FeCrVO multi-principal alloy, the atomic percentage expression of the alloy composition is Fe a Cr b V c o d , wherein 20≤a≤35, 20≤b≤35, 20≤c≤35, 0<d≤3, a+b+c+d=100.

Embodiment 2

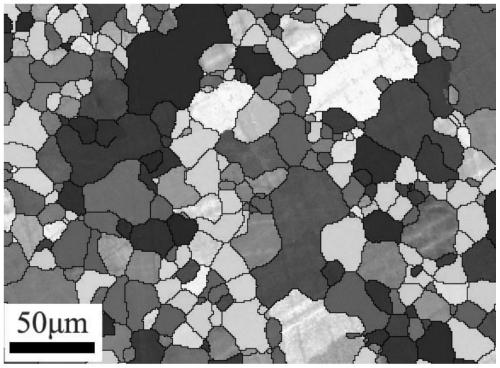

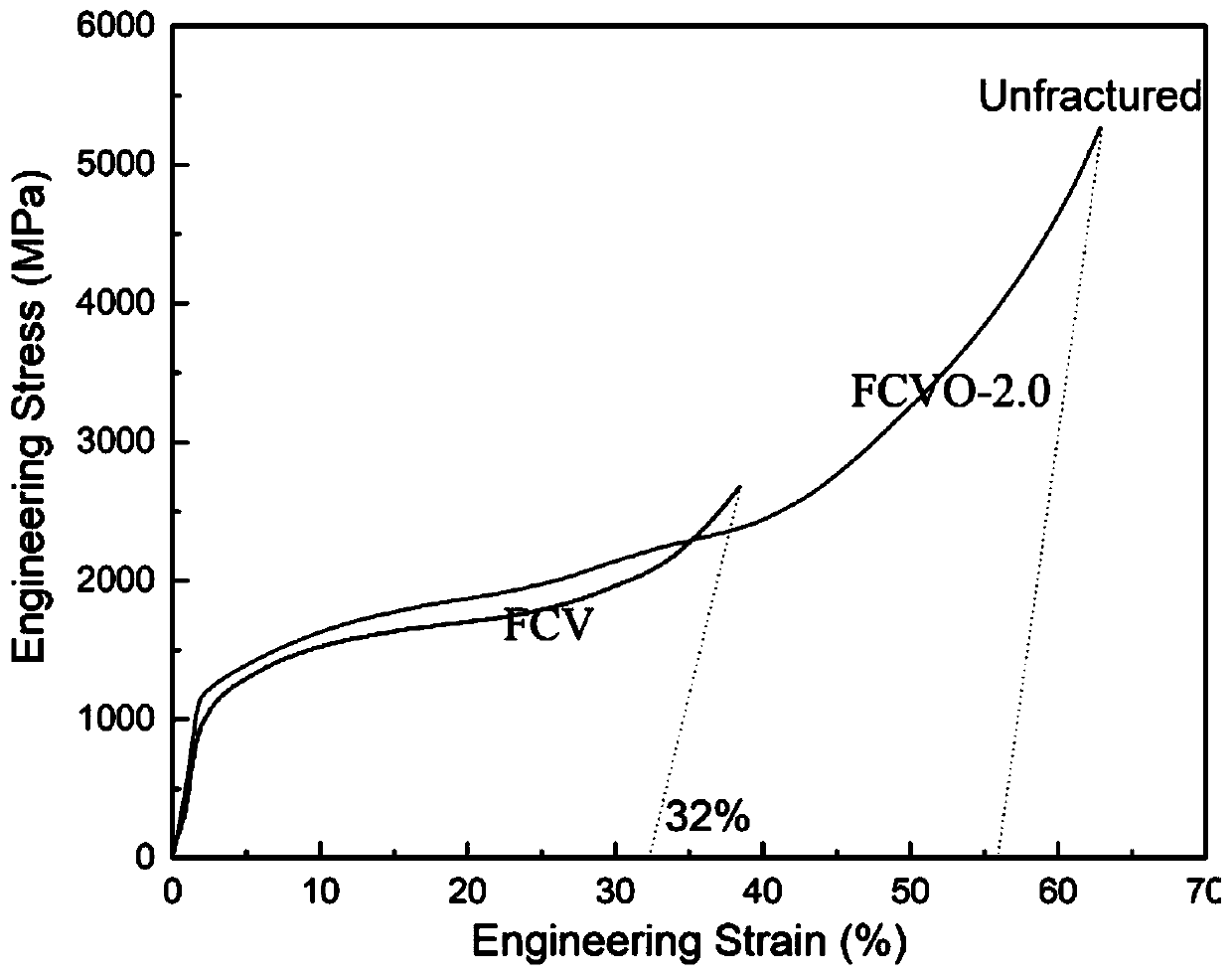

[0036] In this embodiment, the high-strength, toughness and low-activation FeCrVO multi-principal alloy, the atomic percentage expression of the alloy composition is Fe a Cr b V c o d , where a=b=c=33.167, d=0.5. The alloy has a simple body-centered cubic structure, the yield strength of the alloy is not lower than 1.1GPa, and the compressive plasticity exceeds 55%.

Embodiment 3

[0038] In this embodiment, the high-strength, toughness and low-activation FeCrVO multi-principal alloy, the atomic percentage expression of the alloy composition is Fe a Cr b V c o d , where a=b=c=33.0, d=1.0. The alloy has a simple body-centered cubic structure, the yield strength of the alloy is not lower than 1.1GPa, and the compressive plasticity exceeds 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| Compressive plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com