Manufacturing method of titanium or titanium alloy thin-wall ball shell

A manufacturing method and technology of titanium alloys, applied in the direction of manufacturing tools, metal processing equipment, plasma welding equipment, etc., can solve the problems of poor plasticity of titanium and titanium alloys, complicated manufacturing methods, and deteriorated weld performance, so as to achieve small residual stress, Improved dimensional accuracy and reduced pressing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

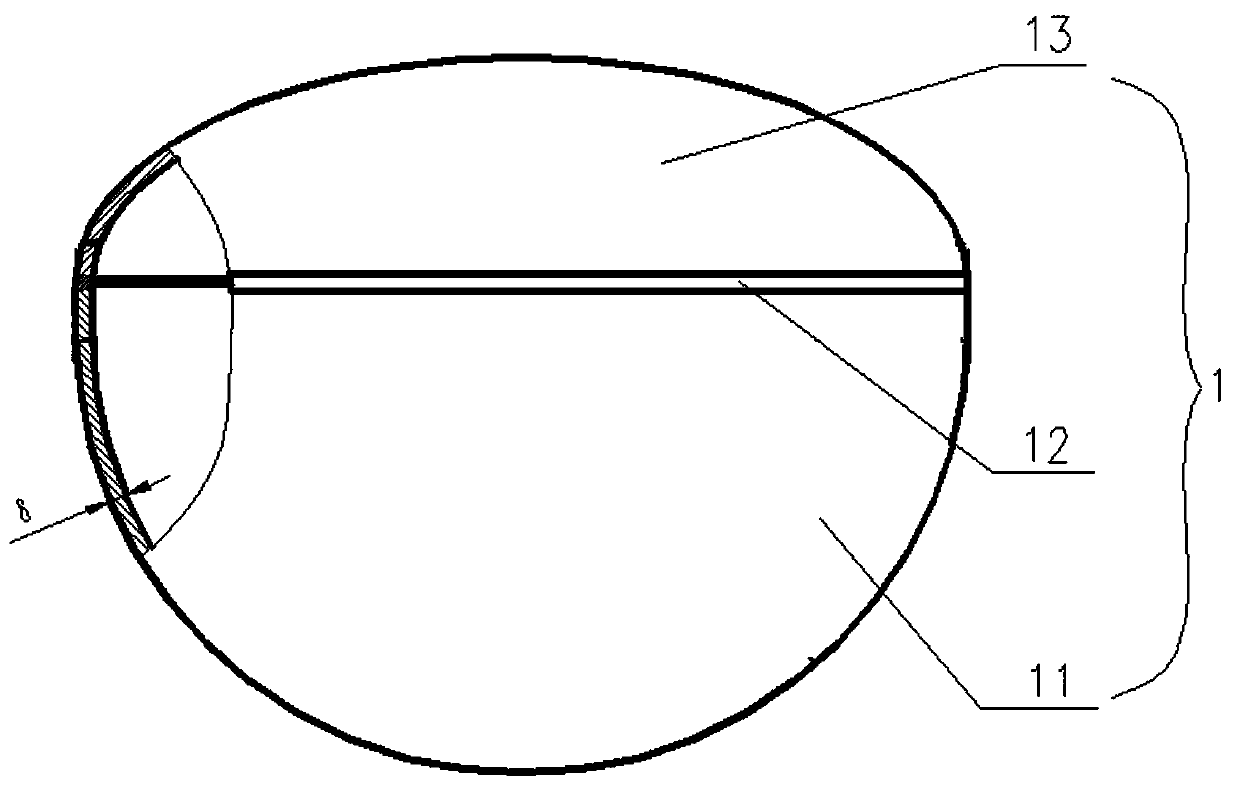

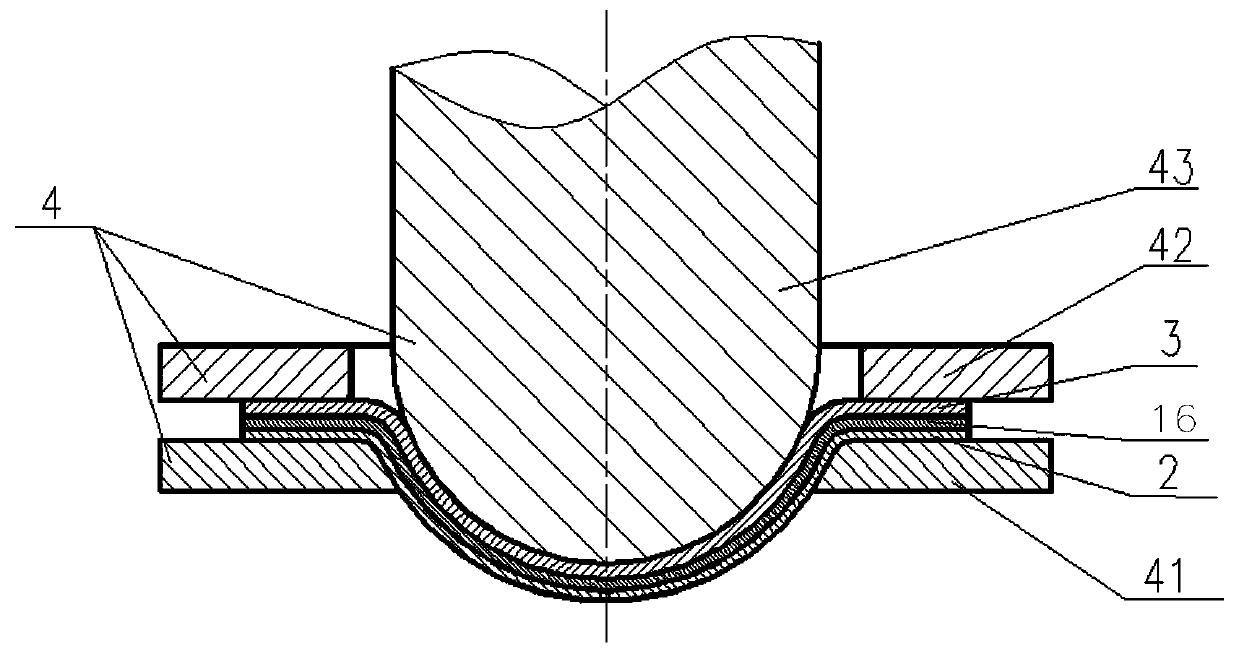

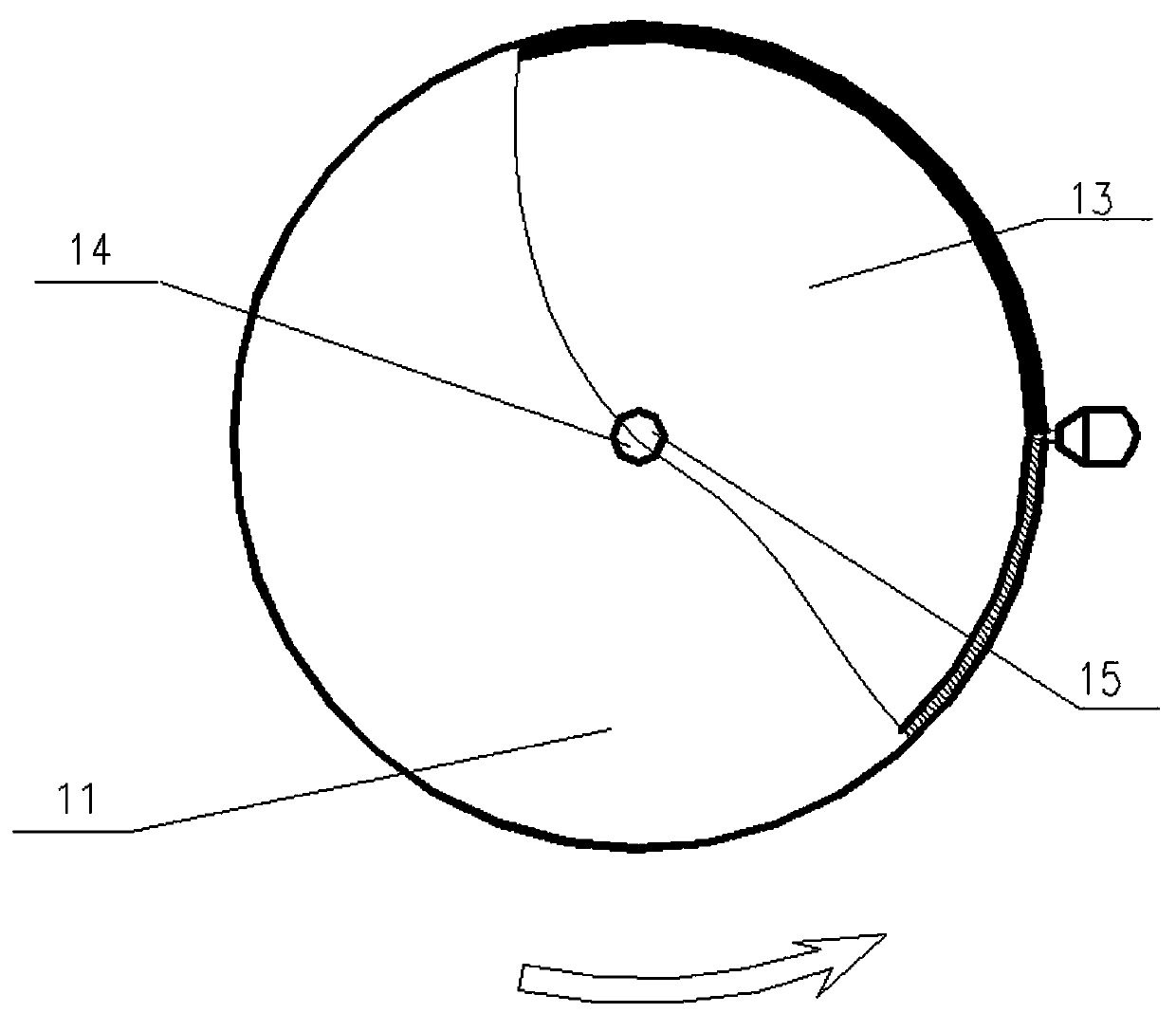

[0035] combine Figure 1 ~ Figure 4 This embodiment will be described. This embodiment provides a method for manufacturing a thin-walled spherical shell 1 of a titanium alloy fire-fighting tank carried by a fire-fighting drone. The thin-walled spherical shell 1 is made of TA5 titanium alloy, and the thickness δ is 4 mm. The first hemispherical shell 11 and the second hemispherical shell 13 are connected by welding seams 12, wherein the first hemispherical shell 11 is in the shape of a hemisphere as a whole, and the second hemispherical shell 13 is in the shape of a semi-oblate spheroid as a whole, which belongs to a semi-hemispherical shape.

[0036] It should be noted that the quasi-hemispherical shape may also be half of a prolate sphere, and the hemispherical shell at this time is a semi-prolate spherical shell, or the quasi-hemispherical shape is half of other spheroidal surfaces.

[0037] A method for manufacturing a thin-walled spherical shell of a titanium alloy fire-f...

Embodiment 2

[0052] This embodiment provides a manufacturing method of a thin-walled spherical shell of a pure titanium anchor buoy, which is basically the same as the manufacturing method provided in Example 1, combined below Figure 1 ~ Figure 4 to illustrate the difference.

[0053] In this embodiment, the thin-walled spherical shell 1 is made of TA2 pure titanium, and the thickness δ is 8mm.

[0054] In the S1 blanking process, the raw material used for the spherical shell plate 16 is a TA2 pure titanium plate with a thickness of δ=8mm.

[0055] In the S2 plastic forming process, the entire assembly is placed flat in a natural gas furnace for heating, the heating temperature is 600° C., and the holding time is 30 minutes.

[0056] In the S4 welding process, the parameters of the plasma arc welding are: current 220A, voltage 26-32V, welding speed 22cm / min, center gas flow 5L / min, annular gas flow 20L / min. During the automatic argon arc vertical welding process, TA2 titanium welding wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com