Preparation method of high-strength and long-life porous nickel-based solid solution for electrolytic hydrogen production

A technology of porous nickel and solid solution, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., to achieve the effect of excellent electrical conductivity, high strength and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

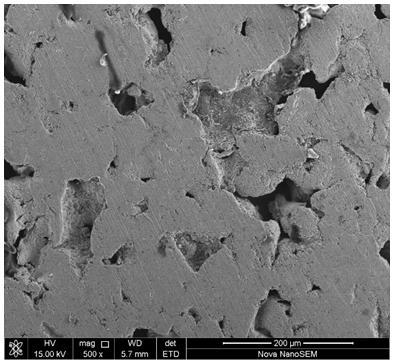

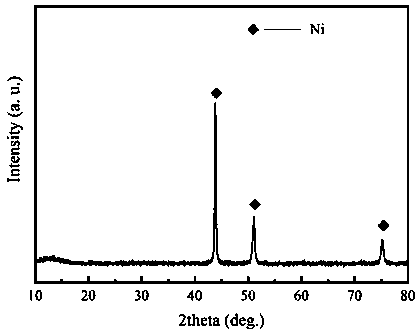

[0020] Iron, cobalt, and nickel powders are prepared in an atomic ratio of 1:3:5, and then Mg powder is added as a pore-forming agent. The mass percentage of Mg powder is 20% of the total mass of iron, cobalt, and nickel powders.

[0021] Then use a tablet press to press into a billet, wherein the pressing pressure is 700Mpa, and the holding time is 30 seconds. Then place the obtained sample in a polycrystalline mullite fiber insulation barrel, and then put the insulation barrel into a microwave sintering furnace; then the vacuum in the furnace cavity is evacuated to less than 0.1 Pa, and then filled with argon with a purity of 99.999%. Control the output power of the microwave sintering furnace, heat it to 1100°C at a heating rate of 45°C / min, keep it for 15 minutes, then close the microwave sintering furnace, let the sample cool down with the furnace to obtain porous nickel that can be used as an anode material for hydrogen production by electrolysis of water base solid solu...

Embodiment 2

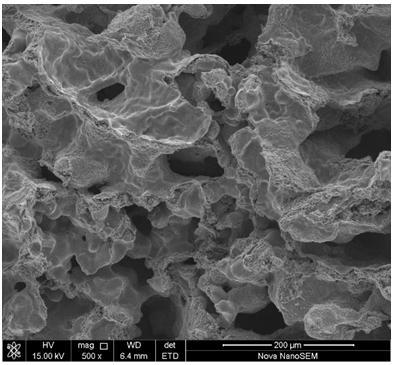

[0030] Iron, cobalt, and nickel powders are prepared in an atomic ratio of 1:3:5, and then Mg powder is added as a pore-forming agent. The mass percentage of Mg powder is 15% of the total mass of iron, cobalt, and nickel powders.

[0031] Then use a tablet press to press into a billet, wherein the pressing pressure is 700Mpa, and the holding time is 30 seconds. Then place the obtained sample in a polycrystalline mullite fiber insulation barrel, and then put the insulation barrel into a microwave sintering furnace; then the vacuum in the furnace cavity is evacuated to less than 0.1 Pa, and then filled with argon with a purity of 99.999%. Control the output power of the microwave sintering furnace, heat it to 1100°C at a heating rate of 45°C / min, keep it for 15 minutes, then close the microwave sintering furnace, let the sample cool down with the furnace to obtain porous nickel that can be used as an anode material for hydrogen production by electrolysis of water base solid solu...

Embodiment 3

[0033] Iron, cobalt, and nickel powders are prepared in an atomic ratio of 1:3:5, and then Mg powder is added as a pore-forming agent. The mass percentage of Mg powder is 10% of the total mass of iron, cobalt, and nickel powders.

[0034] Then use a tablet press to press into a billet, wherein the pressing pressure is 700Mpa, and the holding time is 30 seconds. Then place the obtained sample in a polycrystalline mullite fiber insulation barrel, and then put the insulation barrel into a microwave sintering furnace; then the vacuum in the furnace cavity is evacuated to less than 0.1 Pa, and then filled with argon with a purity of 99.999%. Control the output power of the microwave sintering furnace, heat it to 1100°C at a heating rate of 45°C / min, keep it for 15 minutes, then close the microwave sintering furnace, let the sample cool down with the furnace to obtain porous nickel that can be used as an anode material for hydrogen production by electrolysis of water base solid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com