Nickel-free low-copper zirconium-based bulk amorphous alloy and preparation method thereof

An amorphous alloy, copper-zirconium-based technology, applied in the field of bulk amorphous alloy materials, to achieve the effects of reduced potential biological toxicity, low copper content, and good mechanical biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

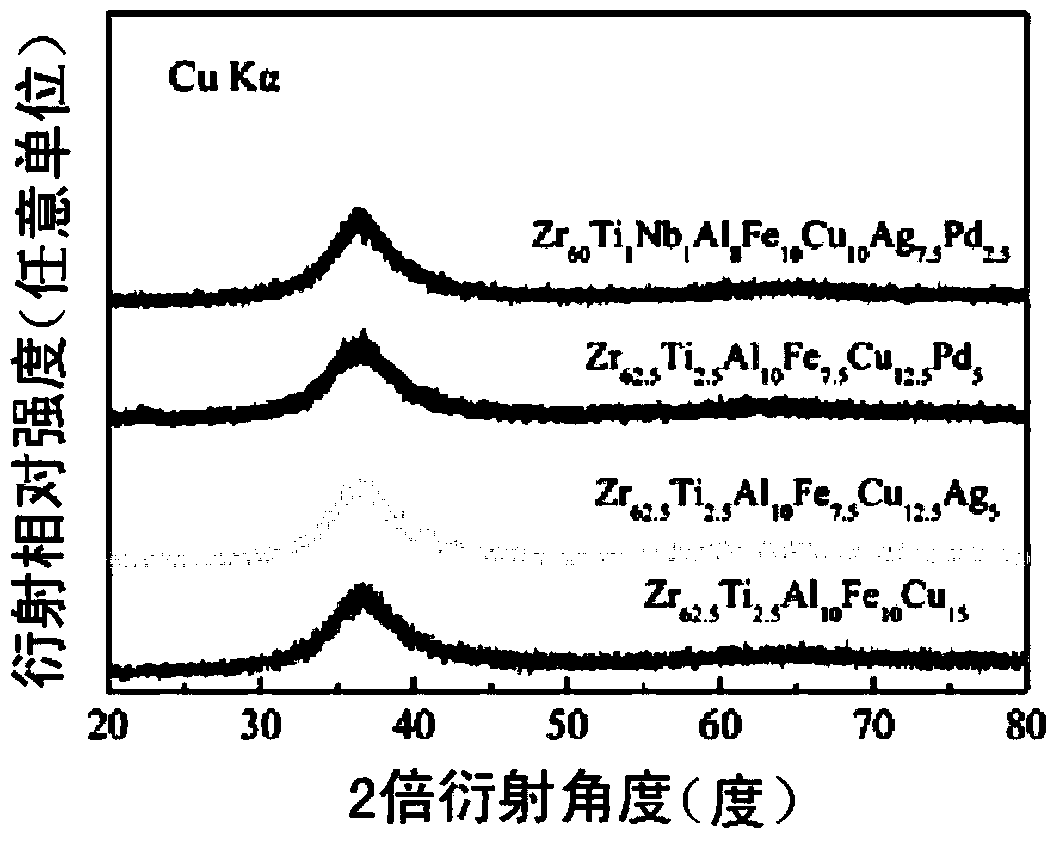

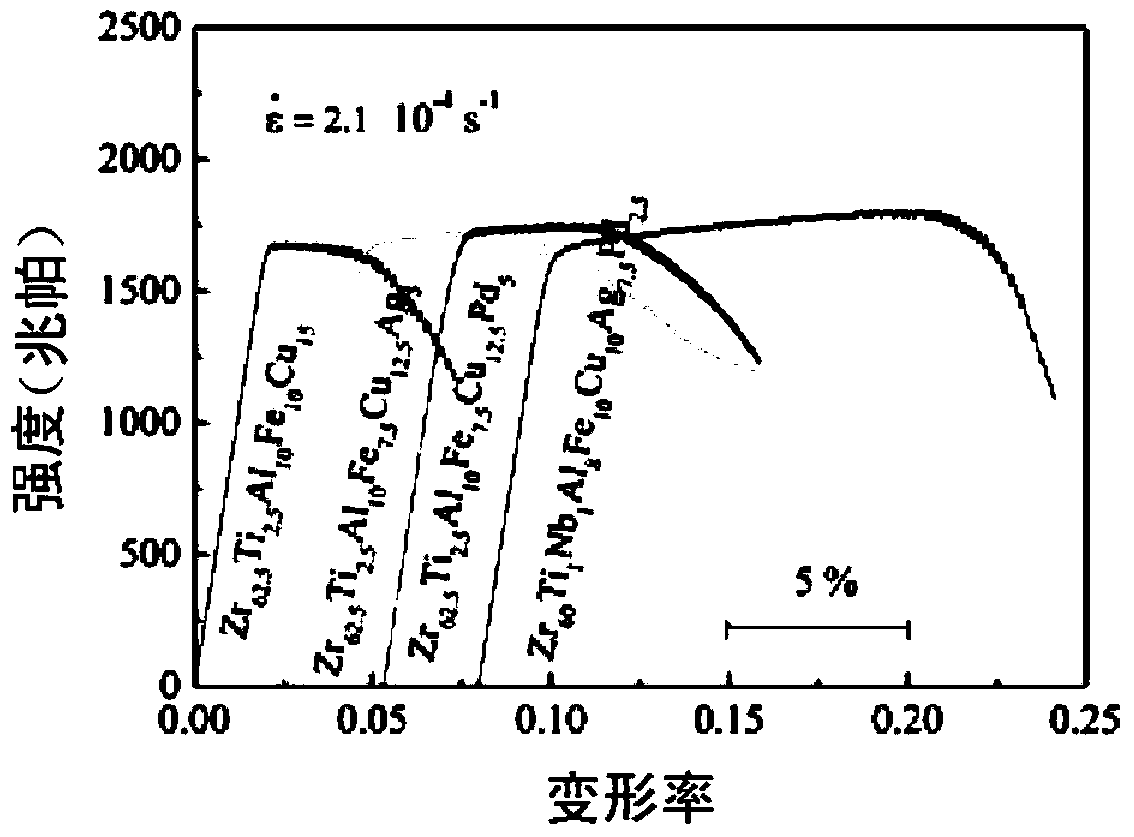

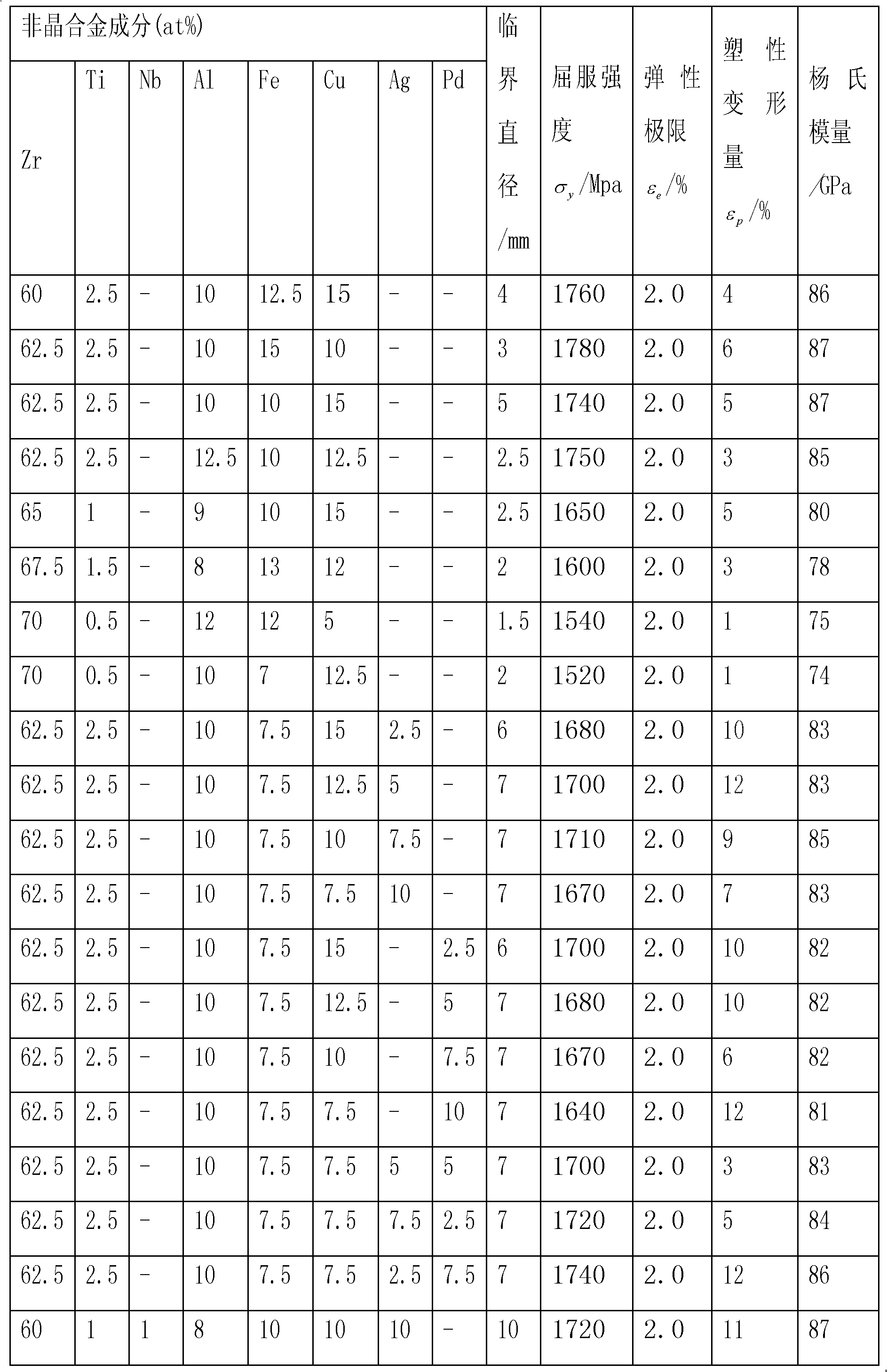

Examples

Embodiment 1

[0032] Zr with a diameter of 5 mm was prepared by copper mold casting 62.5 Ti 2.5 Al 10 Fe 10 Cu 15 bulk amorphous alloy

[0033] Step 1: Ingredients

[0034] Press Zr 62.5 Ti 2.5 Al 10 Fe 10 Cu 15 The nominal composition weighs raw materials;

[0035] Wherein, the mass percentage purity of zirconium (Zr) is 99.8%; the mass percentage purity of titanium (Ti) is 99.99%; the mass percentage purity of copper (Cu) is 99.98%; the mass percentage purity of iron (Fe) is 99.8%; The mass percent purity of aluminum (Al) is 99.9%.

[0036] Step 2: Smelting Zr 62.5 Ti 2.5 Al 10 Fe 10 Cu 15 Master Alloy

[0037] Put the raw material weighed in step 1 into the vacuum melting furnace;

[0038] Adjust the vacuum degree of the vacuum chamber of the vacuum smelting furnace to 5×10 -3 Pa, and then filled with high-purity argon to make the vacuum of the vacuum chamber to 0.5×10 5 Pa;

[0039] After arc melting for 240s, the arc is broken to form the first alloy ingot;

[004...

Embodiment 2

[0054] This embodiment adopts copper mold casting method to prepare the Zr that diameter is 7mm 62.5 Ti 2.5 Al 10 Fe 7.5 Cu 12.5 Ag 5 bulk amorphous alloy.

[0055] Step 1: Ingredients

[0056] Press Zr 62.5 Ti 2.5 Al 10 Fe 7.5 Cu 12.5 Ag 5 The nominal composition weighs raw materials;

[0057] Wherein, the mass percentage purity of zirconium (Zr) is 99.8%; the mass percentage purity of titanium (Ti) is 99.99%; the mass percentage purity of copper (Cu) is 99.98%; the mass percentage purity of iron (Fe) is 99.8%; The mass percentage purity of aluminum (Al) is 99.9%; the mass percentage purity of silver (Ag) is 99.9%.

[0058] Step 2: Smelting Zr 62.5 Ti 2.5 Al 10 Fe 7.5 Cu 12.5 Ag 5 Master Alloy

[0059] Put the raw material weighed in step 1 into the vacuum melting furnace;

[0060] Adjust the vacuum degree of the vacuum chamber of the vacuum smelting furnace to 3×10 -3 Pa, and then filled with high-purity argon to make the vacuum of the vacuum chamber to...

Embodiment 3

[0072] This embodiment adopts copper mold casting method to prepare the Zr that diameter is 7mm 62.5 Ti 2.5 Al 10 Fe 7.5 Cu 12.5 PD 5 bulk amorphous alloy.

[0073] Step 1: Ingredients

[0074] Press Zr 62.5 Ti 2.5 Al 10 Fe 7.5 Cu 12.5 PD 5 The nominal composition weighs raw materials;

[0075]Wherein, the mass percentage purity of zirconium (Zr) is 99.8%; the mass percentage purity of titanium (Ti) is 99.99%; the mass percentage purity of copper (Cu) is 99.98%; the mass percentage purity of iron (Fe) is 99.8%; The mass percent purity of aluminum (Al) is 99.9%; the mass percent purity of palladium (Pd) is 99.95%.

[0076] Step 2: Smelting Zr 62.5 Ti 2.5 Al 10 Fe 7.5 Cu 12.5 PD 5 Master Alloy

[0077] Put the raw material weighed in step 1 into the vacuum melting furnace;

[0078] Adjust the vacuum degree of the vacuum chamber of the vacuum smelting furnace to 4×10 -3 Pa, and then filled with high-purity argon to make the vacuum of the vacuum chamber to 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com