Intermittent direct-current (DC) magnetron sputtering preparation method of amorphous cobalt-based magnetic film

A technology of DC magnetron sputtering and magnetic thin films, which is applied in the application of magnetic films to substrates, magnetic materials, magnetic objects, etc. It can solve problems such as difficult sputtering of amorphous films, inability to form amorphous, and insufficient cooling speed , to achieve the effects of simple process, high degree of amorphousness and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

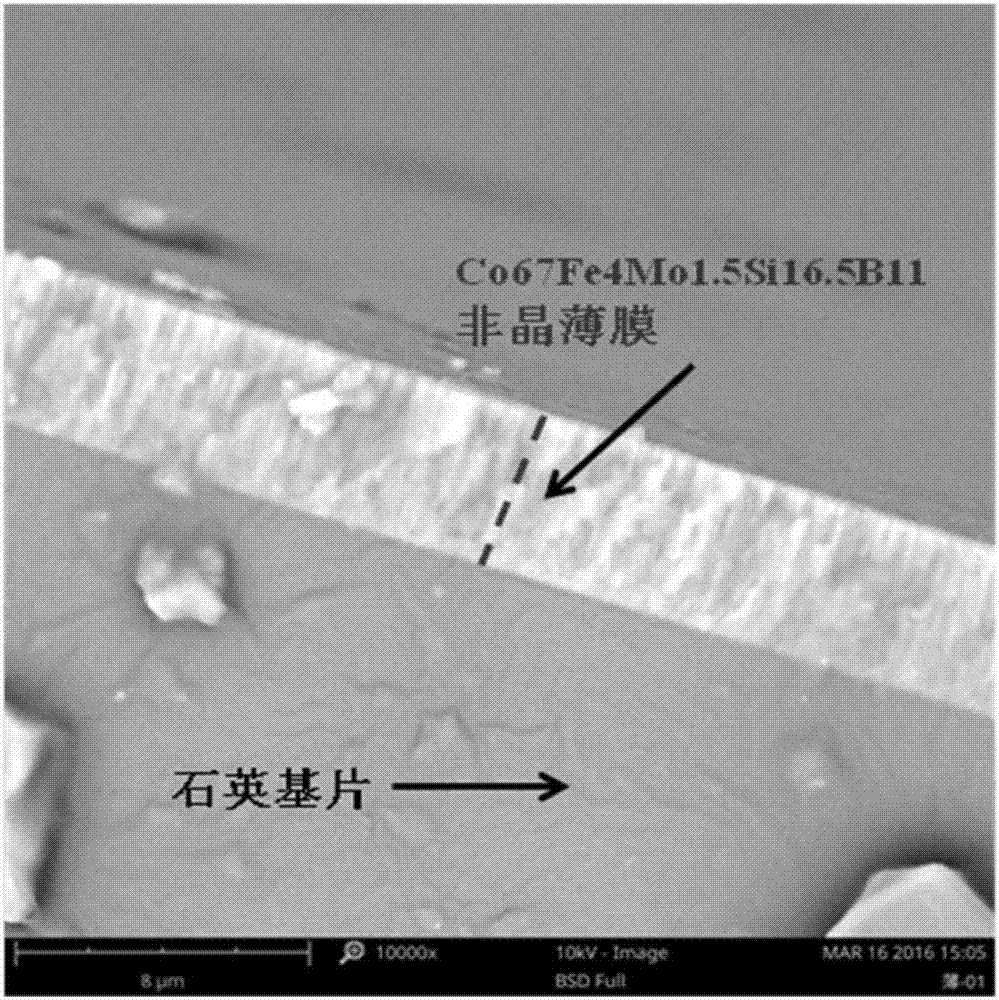

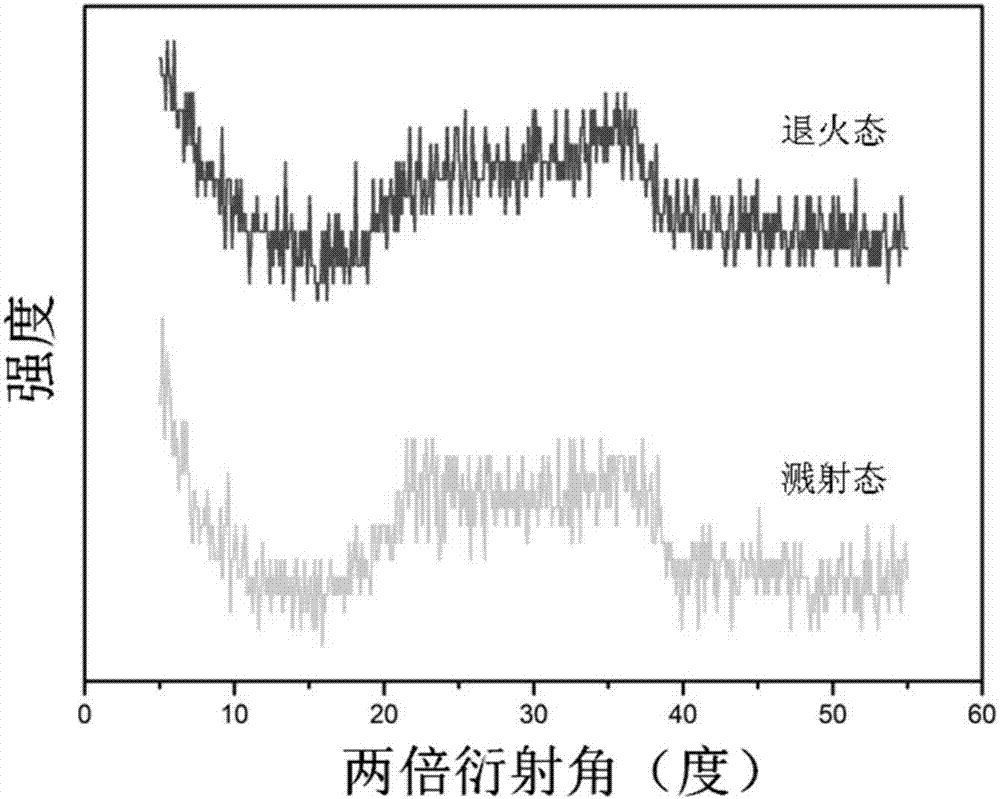

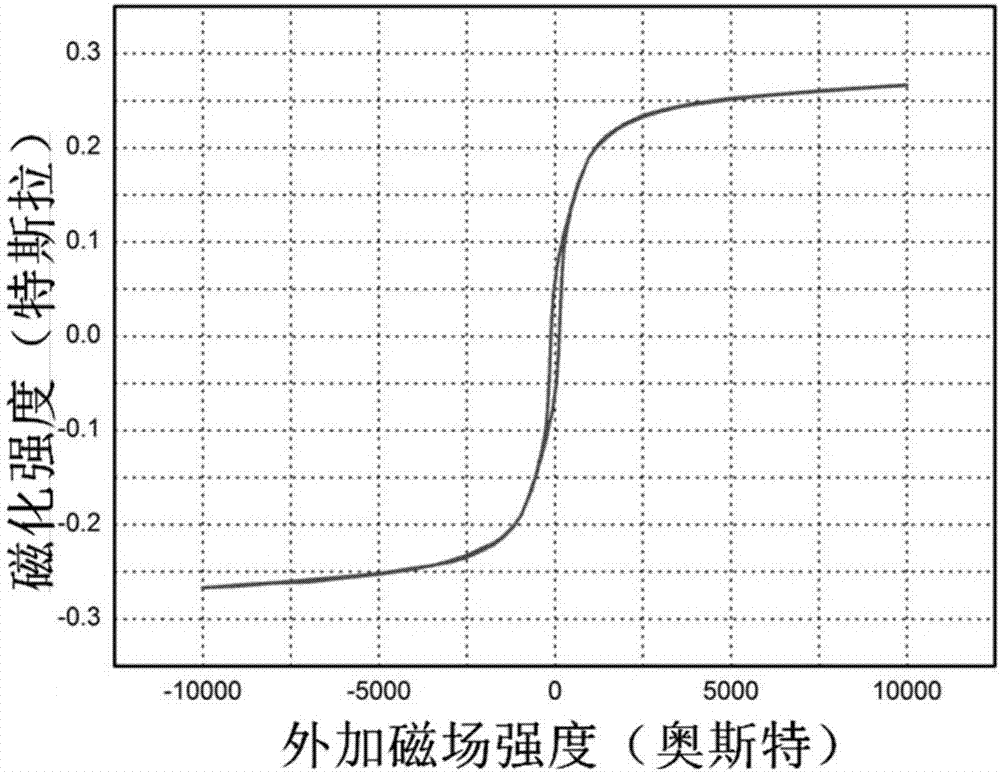

[0027] First, fix the molybdenum target and the quartz substrate in a DC magnetron sputtering apparatus. Vacuum the sputtering chamber to make the vacuum better than 5x10 -4 Pa, open the argon valve to feed argon, and control the partial pressure of argon to 0.4Pa, adjust the flow of the argon valve, control the flow of argon to 200ml / min, open the voltage control knob and control the sputtering power to 150W, and then Sputter on the quartz substrate for 15 minutes to obtain a stress buffer layer with a thickness of about 200 nm. Then replace the molybdenum target with Co 67 Fe x Mo 5.5-x Si y B 27-y The target is sputtered under the same sputtering process, the sputtering baffle is closed for 13 minutes every 10 minutes of sputtering, and the temperature of the quartz substrate is controlled between 50-70°C. After the effective sputtering time reaches 1.5h, stop sputtering, close the argon gas valve, and open the cavity after the temperature of the quartz substrate is c...

Embodiment 2

[0030] First, fix the tungsten target and the quartz substrate in a DC magnetron sputtering apparatus. Vacuum the sputtering chamber to make the vacuum better than 5x10 -4 Pa, open the argon valve to feed argon, and control the partial pressure of argon to 1.2Pa, adjust the flow rate of the argon valve, control the flow rate of argon gas to 40ml / min, open the voltage control knob and control the sputtering power to 120W, first in the quartz Sputter on the substrate for 20 minutes to obtain a stress buffer layer with a thickness of about 300 nm. Then replace the tungsten target with Co 67 Fe x Mo 5.5-x Si y B 27-y The target is sputtered, and the sputtering baffle is closed for 10 minutes every 10 minutes of sputtering, and the temperature of the substrate is controlled between 50-70°C. After the effective sputtering time reaches 2 hours, stop the sputtering, close the argon gas valve, and open the cavity to take out the sputtered Co 67 Fe x Mo 5.5-x Si y B 27-y film...

Embodiment 3

[0033] First, fix the titanium target and the quartz substrate in a DC magnetron sputtering apparatus. Vacuum the sputtering chamber to make the vacuum better than 5x10 -4 Pa, open the argon valve to feed argon, and control the partial pressure of argon to 0.8Pa, adjust the flow of the argon valve, control the flow of argon to 100ml / min, open the voltage control knob and control the sputtering power to 180W, first use Sputter on the quartz substrate for 15 minutes to obtain a stress buffer layer with a thickness of about 250 nm. Then replace the tungsten target with Co 67 Fe x Mo 5.5-x Si y B 27-y The target is sputtered, and the sputtering baffle is closed for 15 minutes every 10 minutes of sputtering, and the temperature of the substrate is controlled between 50-70°C. After the effective sputtering time reaches 1h, stop sputtering, close the argon gas valve, and open the cavity to take out the sputtered Co 67 Fe x Mo 5.5-x Si y B 27-y film.

[0034] Then, place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com