Alloying-based high-silicon thin steel strip and preparation method thereof

A high-silicon steel and alloying technology, applied in the field of high-silicon steel strips, can solve problems such as complex production processes, and achieve the effects of reducing impurity content, improving low-temperature ductility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

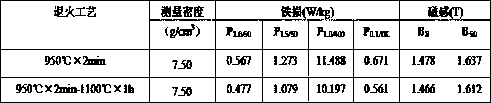

Embodiment 1

[0030] A high-silicon steel strip based on alloying and a preparation method thereof. The silicon content of the high silicon steel thin strip is 5.5-6.0wt%, the copper content is 0.05-0.4wt%, and the rest is iron and unavoidable impurities.

[0031] The preparation method based on the alloyed high-silicon steel thin strip is:

[0032] (1) raw material preparation: according to the chemical composition of the high-silicon steel strip, industrial pure iron, commercial silicon and pure copper are used as raw material ingredients;

[0033] (2) Smelting: The raw materials are smelted in an intermediate frequency vacuum induction furnace, and cast into slabs at 1300°C~1400°C;

[0034] (3) Forging: forging the billet into a slab with a thickness of 15~20mm at 750°C~900°C;

[0035] (4) Hot rolling: the slab is hot rolled into a thin strip with a thickness of 0.6~0.8mm at 700°C~900°C;

[0036] (5) Warm rolling: the thin strip is warm-rolled to 0.2-0.3mm at 150°C-400°C to obtain all...

Embodiment 2

[0039] A high-silicon steel strip based on alloying and a preparation method thereof. The silicon content of the high silicon steel strip is 5.8-6.5wt%, the copper content is 0.3-1.2wt%, and the rest is iron and unavoidable impurities.

[0040]The preparation method based on the alloyed high-silicon steel thin strip is:

[0041] (1) raw material preparation: according to the chemical composition of the high-silicon steel strip, industrial pure iron, commercial silicon and pure copper are used as raw material ingredients;

[0042] (2) Smelting: The raw materials are smelted in an intermediate frequency vacuum induction furnace, and cast into slabs at 1350°C~1450°C;

[0043] (3) Forging: forging the billet into a slab with a thickness of 15~20mm at 850°C~1000°C;

[0044] (4) Hot rolling: hot rolling the slab into a thin strip with a thickness of 0.6~0.8mm at 850°C~1000°C;

[0045] (5) Warm rolling: Warm rolling the thin strip to 0.2~0.3mm at 250°C~500°C to obtain alloyed high...

Embodiment 3

[0048] A high-silicon steel strip based on alloying and a preparation method thereof. The silicon content of the high silicon steel thin strip is 6.2-6.8wt%, the copper content is 1.0-1.8wt%, and the rest is iron and unavoidable impurities.

[0049] The preparation method based on the alloyed high-silicon steel thin strip is:

[0050] (1) raw material preparation: according to the chemical composition of the high-silicon steel strip, industrial pure iron, commercial silicon and pure copper are used as raw material ingredients;

[0051] (2) Smelting: The raw materials are smelted in an intermediate frequency vacuum induction furnace, and cast into slabs at 1450°C~1550°C;

[0052] (3) Forging: forging the billet into a slab with a thickness of 10~16mm under the condition of 1000℃~1150℃;

[0053] (4) Hot rolling: the slab is hot rolled into a thin strip with a thickness of 0.6~0.8mm at 950°C~1150°C;

[0054] (5) Warm rolling: Warm rolling the thin strip to 0.2~0.3mm at 350°C~6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com