Shell distributed catalyst and application thereof

A catalyst and shell technology, which is applied to the catalyst distributed in the shell and its application field, can solve the problems of reducing the probability of carbon chain growth, reducing selectivity, affecting binding, etc., and achieving the effects of good stability, high activity, and strong binding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

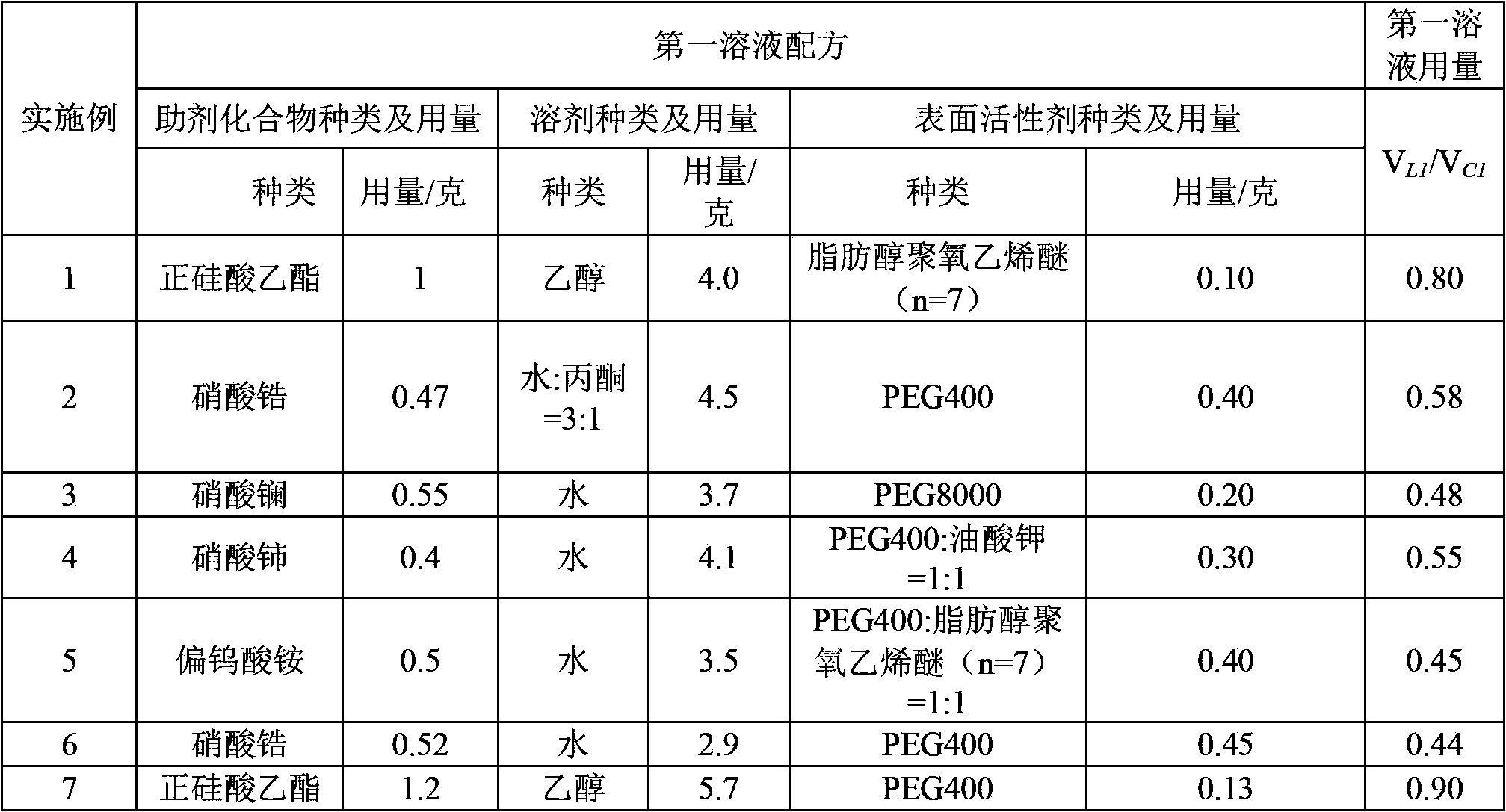

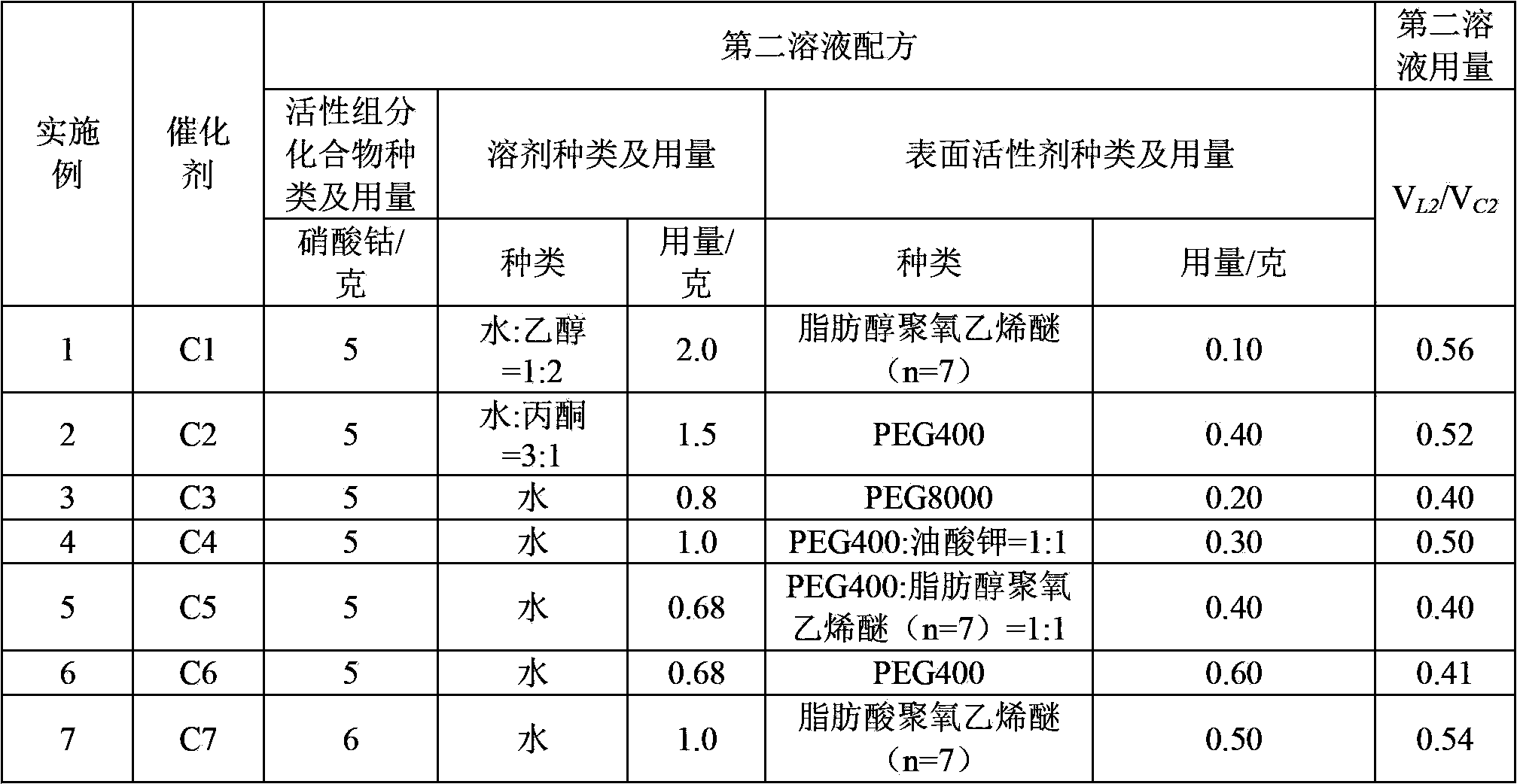

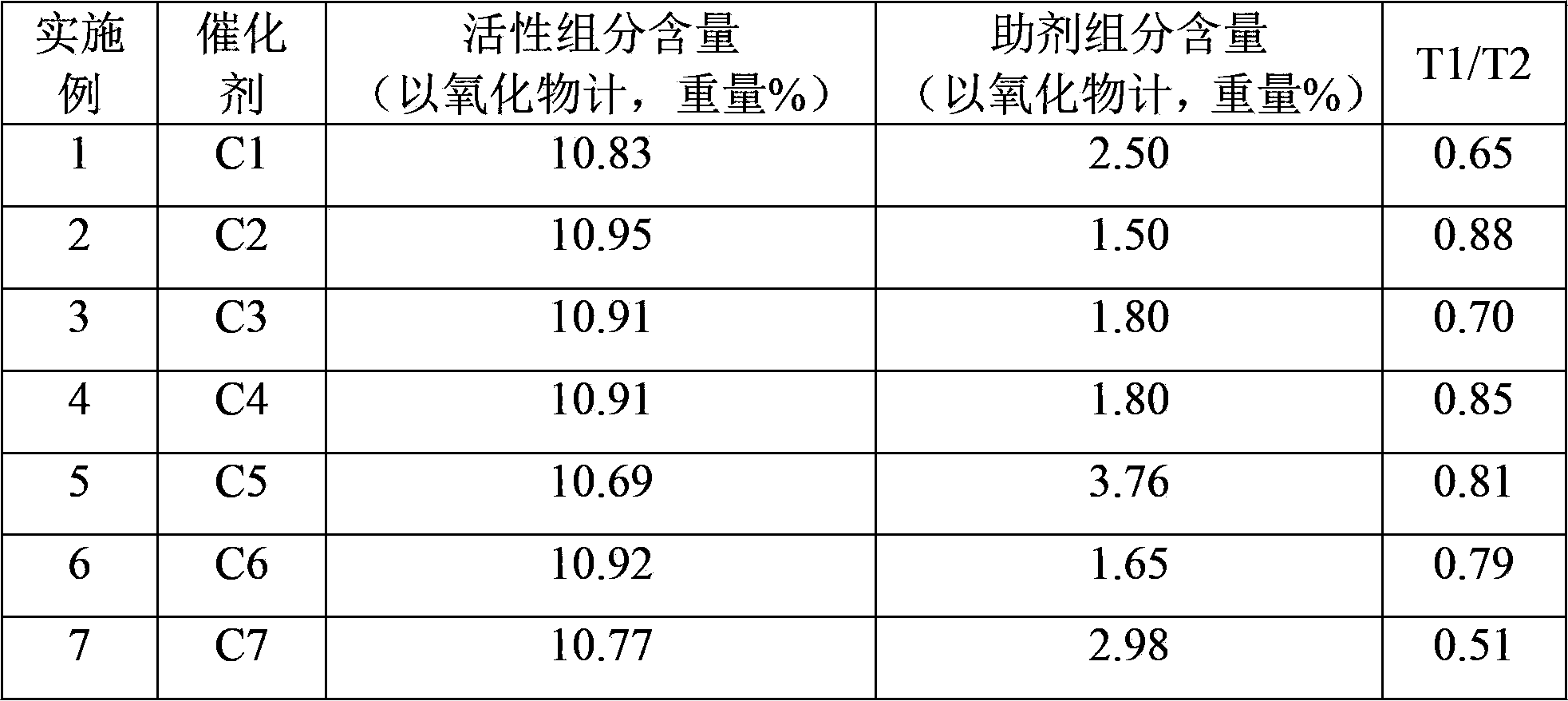

[0049] Carriers used in Examples 1-4 are spherical silica particles (particle diameter is 2-4 mm, water absorption rate is 0.8 milliliters / gram), and carriers used in Examples 5-7 are cylindrical gamma-alumina particles (diameter of particle bottom surface is 2-4 mm, the particle height is 2-8 mm, and the water absorption rate is 0.8 ml / g), the amount of the carrier is 10 grams, and the first solution is prepared according to the materials listed in Table 1 and the carrier is impregnated, and the immersion time is 5 After impregnation, dry at 140°C for 4 hours, and bake at 450°C for 4 hours to obtain the carrier loaded with auxiliary components, and then prepare the second solution according to the materials listed in Table 2 and impregnate the aforementioned carriers loaded with auxiliary components respectively. The carrier is impregnated for 5 minutes, dried at 140°C for 4 hours after impregnated, and then calcined at 450°C for 4 hours to obtain catalysts C1-C7 loaded with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com