Method for in-situ synthesis of metal phthalocyanine/carbon nano-tube compound

A carbon nanotube and metal phthalocyanine technology, which is applied in the field of in-situ synthesis of metal phthalocyanine/carbon nanotube composites, can solve the problem of easy shedding, difficulty in controlling the uniform distribution of molecules, and the loose combination of phthalocyanine molecules and carbon nanotubes and other issues to achieve a solid combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Take 0.10 g of multi-walled carbon nanotubes with a diameter of 50-70 nm and a length of 20 μm, add them to 40 ml of nitrobenzene, oscillate and disperse under ultrasonic waves for 20 minutes, and obtain a suspension of carbon nanotubes;

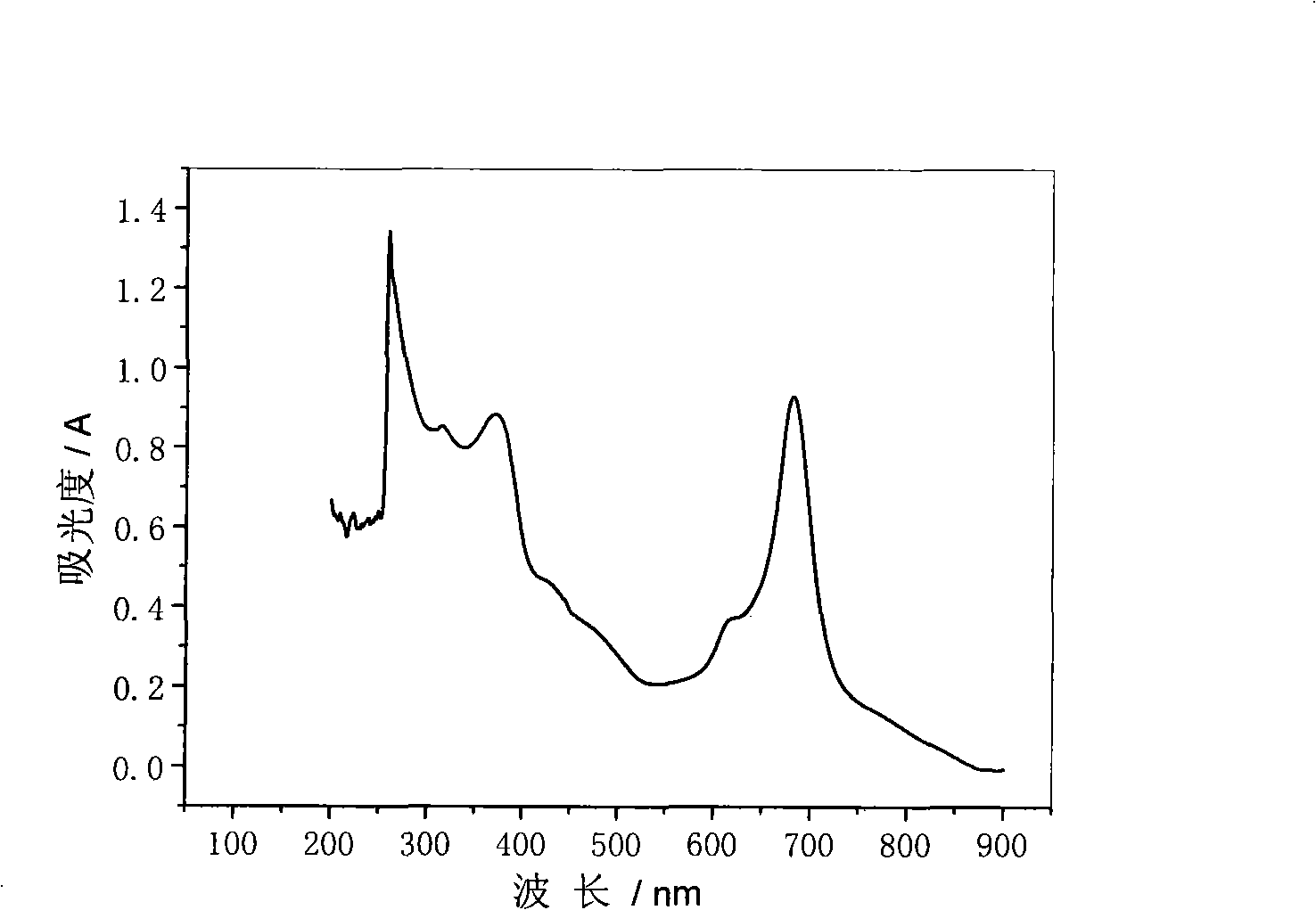

[0022] 2) 0.76g o-dicyanobenzene, 0.18g 1,2,4,5-benzene tetracarbonitrile and 0.22g FeCl 2 4H 2 After O grinding and mixing, add to the carbon nanotube suspension in step 1), under the protection of nitrogen, stir and react at 200°C for 4h, after the product is filtered, it is rinsed with absolute ethanol until the filtrate is colorless, and the product is obtained at 80 ℃ vacuum drying for 24h to obtain the binuclear iron phthalocyanine / carbon nanotube composite, with figure 1 It is the electronic absorption spectrum of the dinuclear iron phthalocyanine / carbon nanotube composite in DMSO, and the Q band maximum absorption peak of the dinuclear iron phthalocyanine appears at 684nm.

Embodiment 2

[0024] 1) Take 0.20 g of multi-walled carbon nanotubes with a diameter of 50-70 nm and a length of 20 μm, add 40 ml of nitrobenzene, oscillate and disperse under ultrasonic waves for 20 minutes, and obtain a suspension of carbon nanotubes;

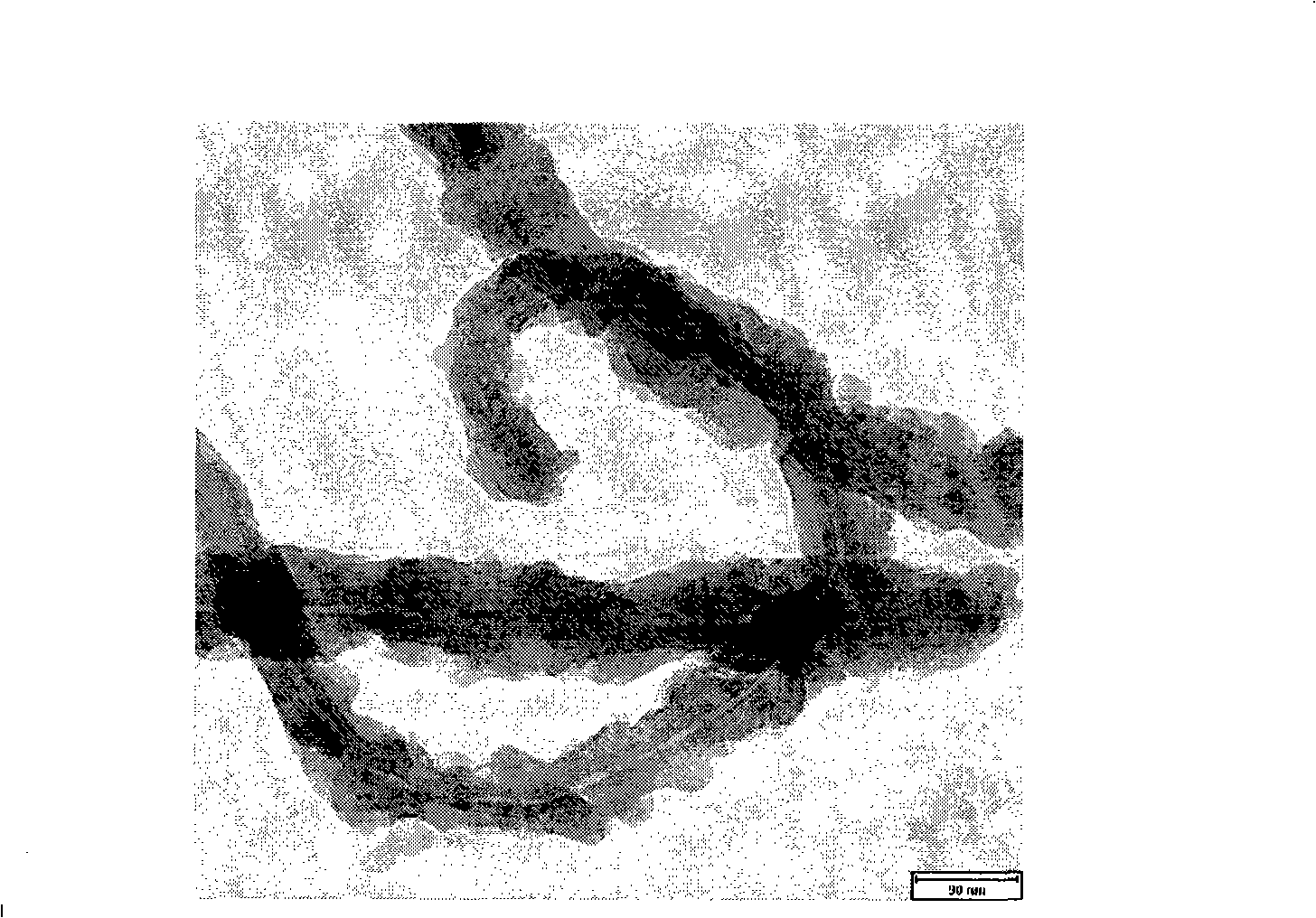

[0025] 2) 0.64g o-dicyanobenzene, 0.18g 1,2,4,5-benzene tetracarbonitrile and 0.22g FeCl 2 4H 2 After O grinding and mixing, add to the carbon nanotube suspension in step 1), under the protection of nitrogen, stir and react at 200°C for 4h, after the product is filtered, it is rinsed with absolute ethanol until the filtrate is colorless, and the product is obtained at 80 ℃ vacuum drying for 24h to obtain the binuclear iron phthalocyanine / carbon nanotube composite, from the attached figure 2 The transmission electron micrographs of the dinuclear iron phthalocyanine / carbon nanotube composites show that the dinuclear iron phthalocyanine is uniformly coated on the surface of the carbon nanotubes.

Embodiment 3

[0027] 1) Take 0.10 g of multi-walled carbon nanotubes with a diameter of 50-70 nm and a length of 20 μm, add 40 ml of nitrobenzene, oscillate and disperse under ultrasonic waves for 40 minutes, and obtain a suspension of carbon nanotubes;

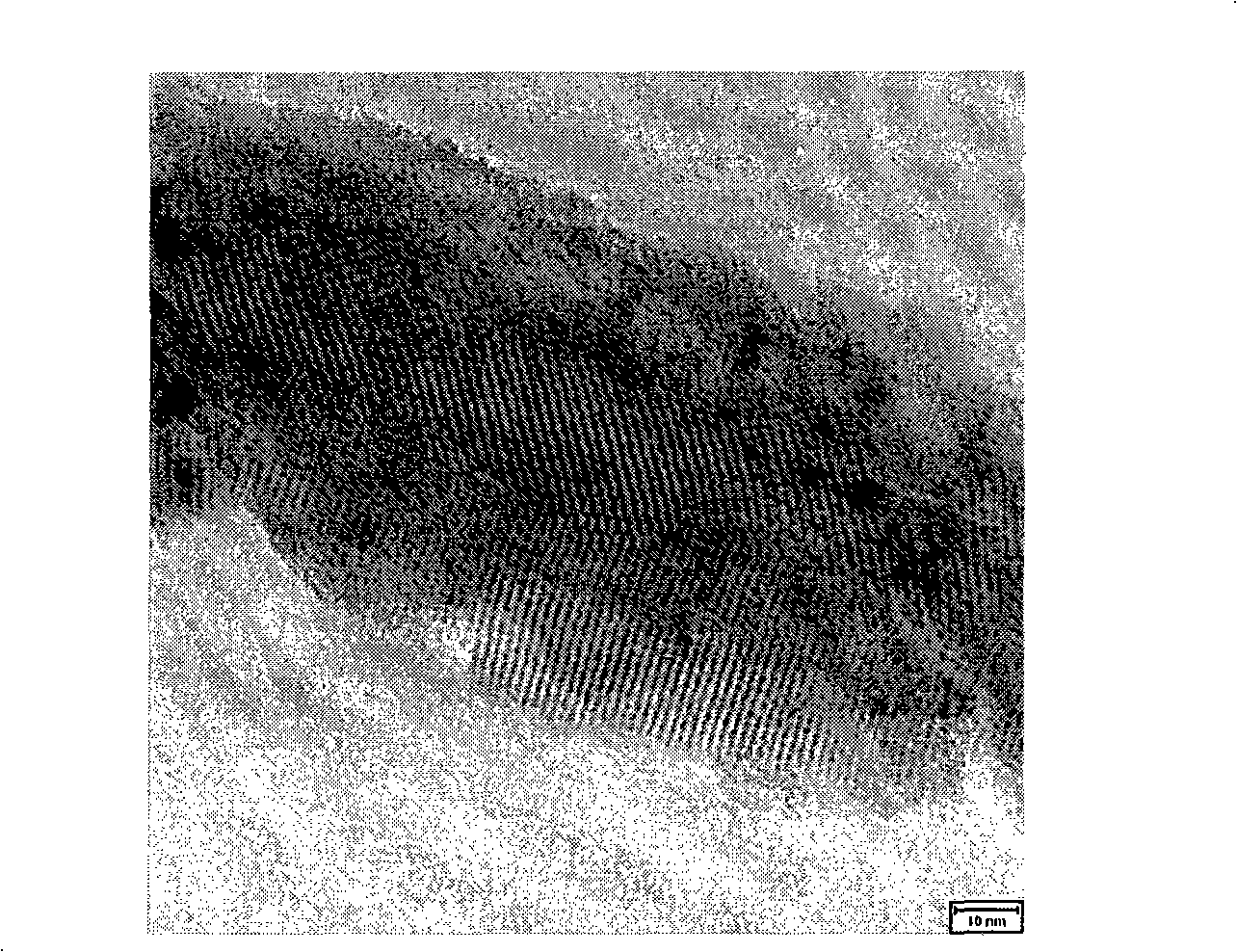

[0028] 2) 0.50g o-dicyanobenzene, 0.18g 1,2,4,5-benzene tetracarbonitrile, 0.22g FeCl 2 4H 2 After O grinding and mixing, add to the carbon nanotube suspension in step 1), under the protection of nitrogen, stir and react at 200°C for 4h, after the product is filtered, it is rinsed with absolute ethanol until the filtrate is colorless, and the product is obtained at 80 ℃ vacuum drying for 24h to obtain the binuclear iron phthalocyanine / carbon nanotube composite, with image 3 It is a high-resolution transmission electron microscope photo of the dinuclear iron phthalocyanine / carbon nanotube composite, and obvious lattice fringes appear in the photo, indicating that the dinuclear iron phthalocyanine forms an ordered microcrystalline structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com