Method for manufacturing bimetal composite wear resistant tube through centrifugal molding double fluids

A technology of centrifugal casting and manufacturing method, which is applied in the field of double-liquid centrifugal casting to manufacture bimetal composite wear-resistant pipes. The effect of safety and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

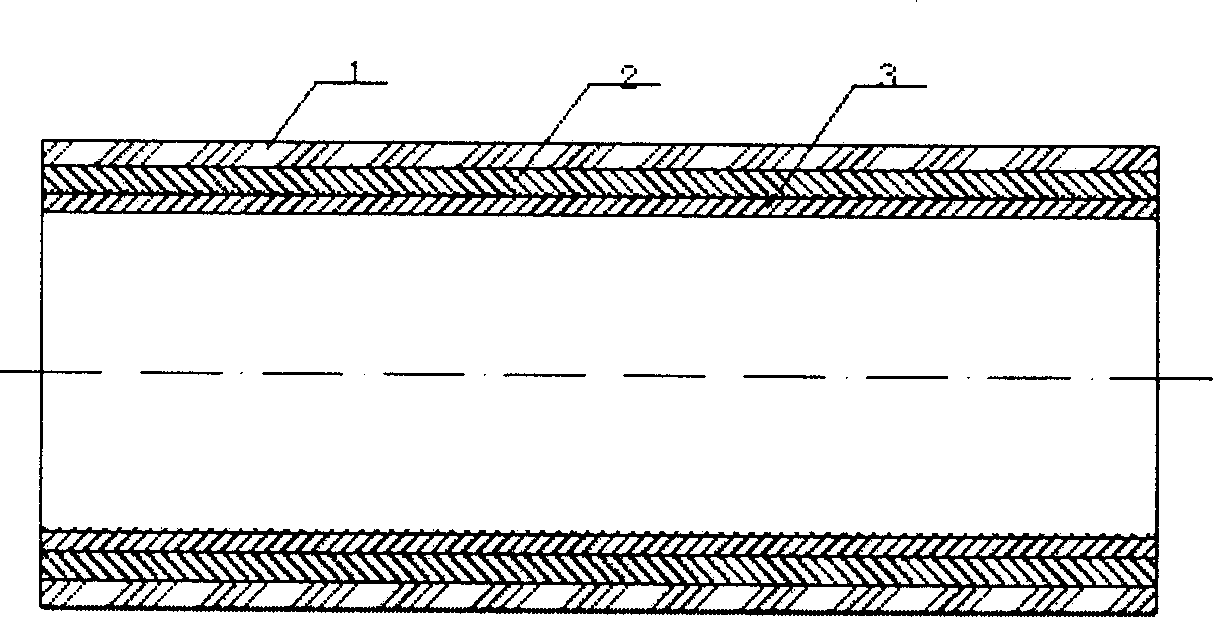

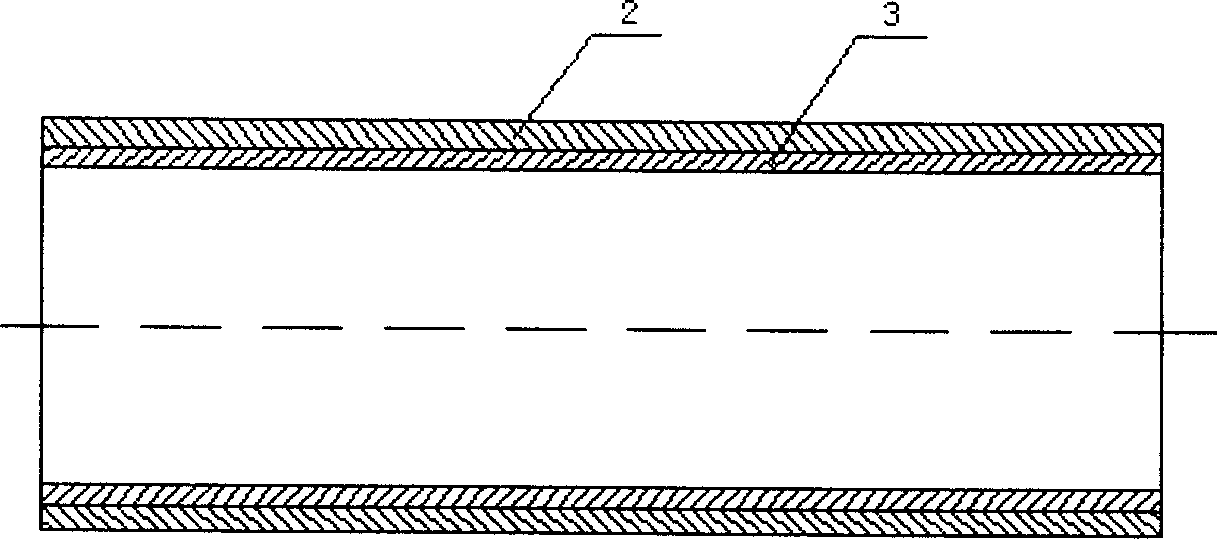

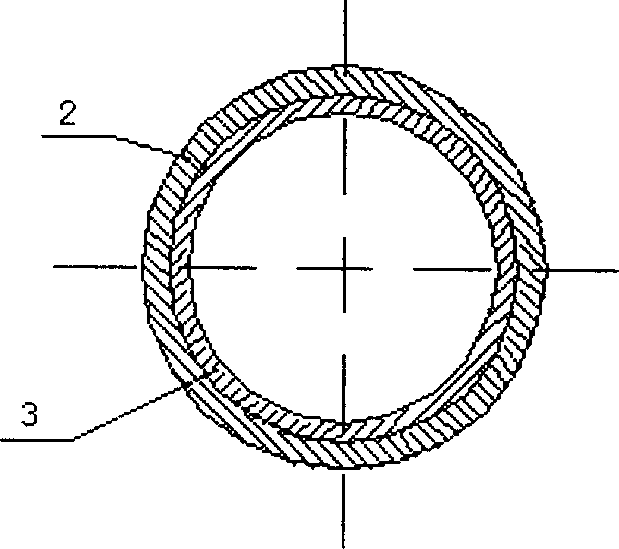

[0023] For the manufacturing method of bimetallic composite wear-resistant pipe by double-liquid centrifugal casting, see the process flow Figure 4 , the structural diagram of the composite wear-resistant pipe in the manufacturing process can be found in figure 1 , follow the steps below:

[0024] a) Paint preparation. Prepare water-based graphite coating according to the volume ratio of water and graphite powder is 1:0.3~1.0, the particle size of graphite powder is generally 10~100um;

[0025] b) The inner surface of the mold tube is sprayed. Spray the prepared water-based graphite paint evenly on the inner surface of the centrifuge mold tube 1, so that the bimetal composite wear-resistant tube can be pulled out from the centrifuge mold tube 1, and its thickness is 0.05-0.15mm;

[0026] c) The paint is dried and the mold tube is packaged. Dry the coating on the inner surface of the mold tube with a flame; and encapsulate the two ends of the centrifuge mold tube 1, and th...

Embodiment 2

[0031] Manufacture a bimetal composite wear-resistant straight pipe with an inner diameter of Φ133mm, a length of 6m, and a lining thickness of 5mm. See the process flow Figure 4 , the structural diagram of the composite wear-resistant pipe in the manufacturing process can be found in figure 1 , proceed as follows:

[0032] a) Paint preparation. According to the volume ratio of water and graphite powder is 1: 0.5 to prepare water-based graphite coating;

[0033] b) The inner surface of the mold tube is sprayed. Spray the prepared water-based graphite paint evenly on the inner surface of the centrifuge mold tube 1, with a thickness of about 0.1mm;

[0034] c) The paint is dried and the mold tube is packaged. drying the coating on the inner surface of the mold tube 1 with a flame; and encapsulating both ends of the centrifuge mold tube 1;

[0035] d) Fabrication of the outer casing. Melt steel smelting, melt A3 steel melt in the intermediate frequency furnace, measure ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com