Method for improving color depth and light fastness of natural dye-dyed fabric

A technology of natural dyes and color depth, which is applied in dyeing, textiles, papermaking, plant fibers, etc. It can solve the problems of poor bonding fastness and no affinity of fibers, so as to improve the coloring depth, improve the bonding fastness, and overcome the sun exposure The effect of fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

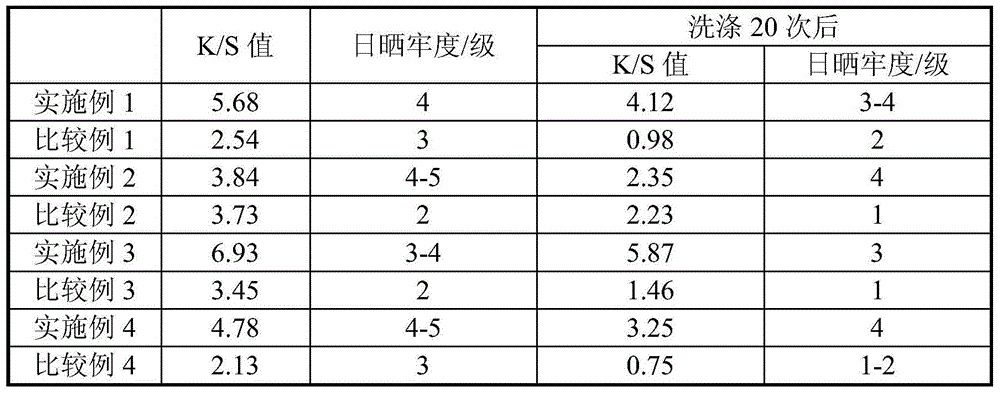

Examples

Embodiment 1

[0019] (1) Pad the pure cotton fabric in an aqueous solution of 4% polyvinylpyrrolidone (molecular weight: 8000) with a solute mass fraction, two dips and two pads, with a spare rate of 100%, and dry at 80°C for 10 minutes. After the drying, cool To room temperature, wash in hot water at 40°C for 15 minutes, then dry naturally, and set aside;

[0020] (2) adopt chestnut shell natural dyestuff to dye the textile processed in step (1), natural dyestuff consumption is 2% (o.w.f), promptly 100 gram textiles need 2g natural dyestuff (referring to 100 grams without step (herein) 1) the original textile of processing needs 2g natural dyestuff, same in the following examples), bath ratio 1:20 (here also refers to the original textile quality and dye liquor mass ratio without step (1) processing, in the following examples The same), the dyeing temperature is 50°C, and the dyeing time is 90min. After the dyeing is finished, the fabric is washed 3 times with water and dried naturally;

...

Embodiment 2

[0028] (1) Pad the silk fabric in an aqueous solution of 8% polyvinylpyrrolidone (molecular weight: 55,000) with a mass fraction of solute, two dips and two pads, with a surplus rate of 80%, and dry at 100°C for 5 minutes. After the drying, cool to room temperature , washed in hot water at 60°C for 10 minutes, then dried naturally, and set aside;

[0029] (2) adopt mulberry natural dyestuff to dye the textiles processed in step (1), the natural dyestuff consumption is 4% (o.w.f), promptly 100 grams of textiles need 4g natural dyestuff, liquor ratio 1:50, dyeing temperature 100 ℃, The dyeing time is 30 minutes. After dyeing, the fabric is washed 5 times with water and dried naturally;

[0030] (3) Dip the natural dye dyed fabric treated in step (2) in zinc acetate dihydrate solution, the dosage of zinc acetate is 15% (o.w.f), the bath ratio is 1:50, the dipping temperature is 70°C, and the dipping time is 60min. After the end, the roll is pressed, and the surplus rate is 100%;...

Embodiment 3

[0037] (1) Pad the wool fabric in an aqueous solution of 6% polyvinylpyrrolidone (molecular weight: 30,000) with a solute mass fraction, two dips and two pads, with a surplus rate of 90%, and dry at 90°C for 7 minutes. After the drying, cool to room temperature , washed in hot water at 50°C for 12 minutes, then dried naturally, and set aside;

[0038] (2) adopt gardenia yellow natural dyestuff to dye the textiles processed in step (1), the natural dyestuff consumption is 3% (o.w.f), promptly 100 grams of textiles need 3g natural dyestuff, liquor ratio 1:40, dyeing temperature 80 ℃, dyeing time is 45min, after dyeing, the fabric is washed 4 times with water and dried naturally;

[0039] (3) Dip the natural dyed fabric treated in step (2) in zinc acetate dihydrate solution, the dosage of zinc acetate is 10% (o.w.f), the bath ratio is 1:40, the dipping temperature is 60°C, and the dipping time is 70min. After the end, roll rolling, the rolling rate is 90%;

[0040] (4) Immerse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com