Method for modifying nanometer titanium dioxide polyester fiber with high photocatalytic activity

A technology of nano-titanium dioxide and polyester fiber, which is applied in fiber treatment, fiber type, textile and papermaking, etc., to achieve the effect of simple process, low production cost and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

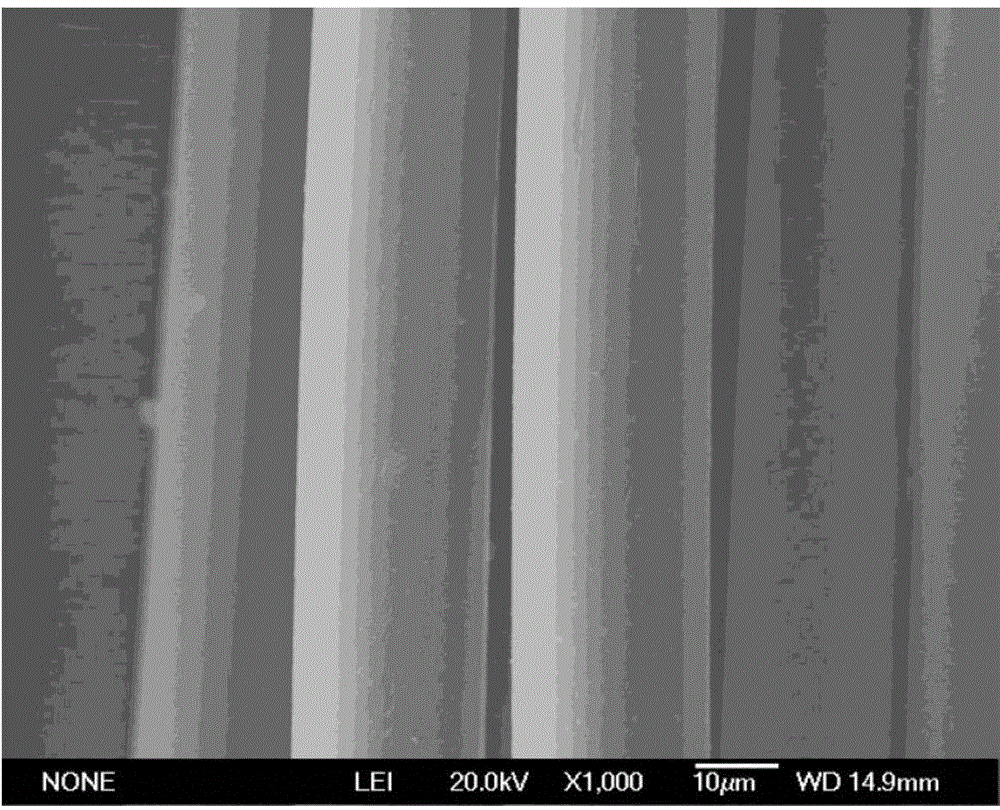

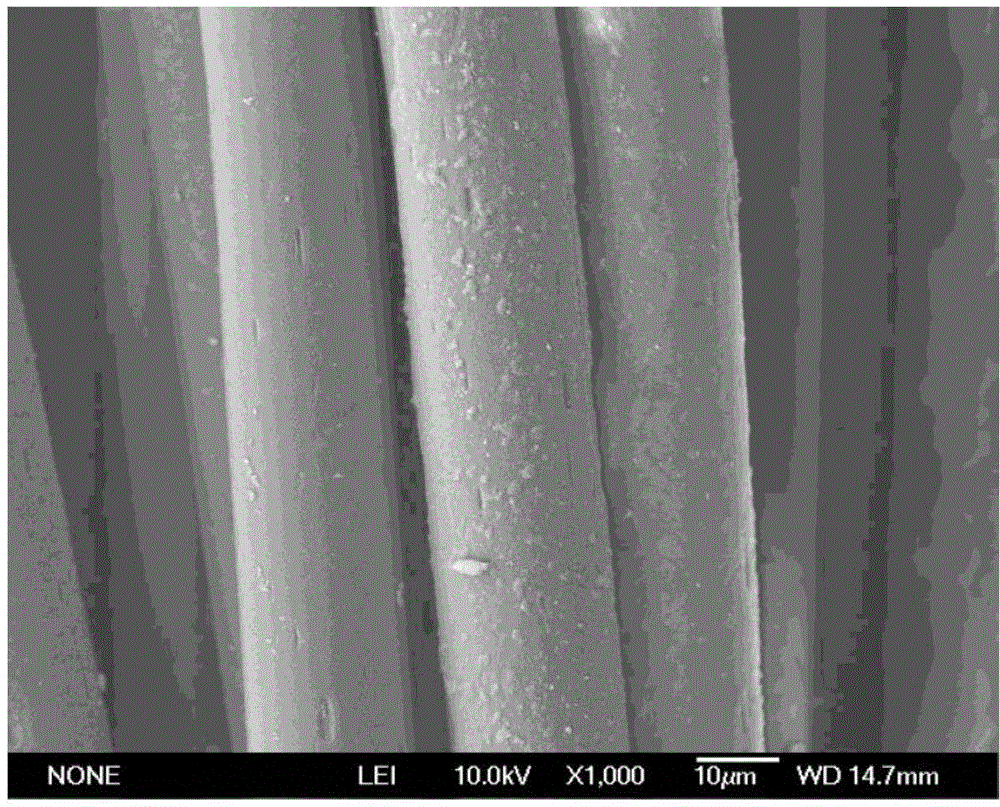

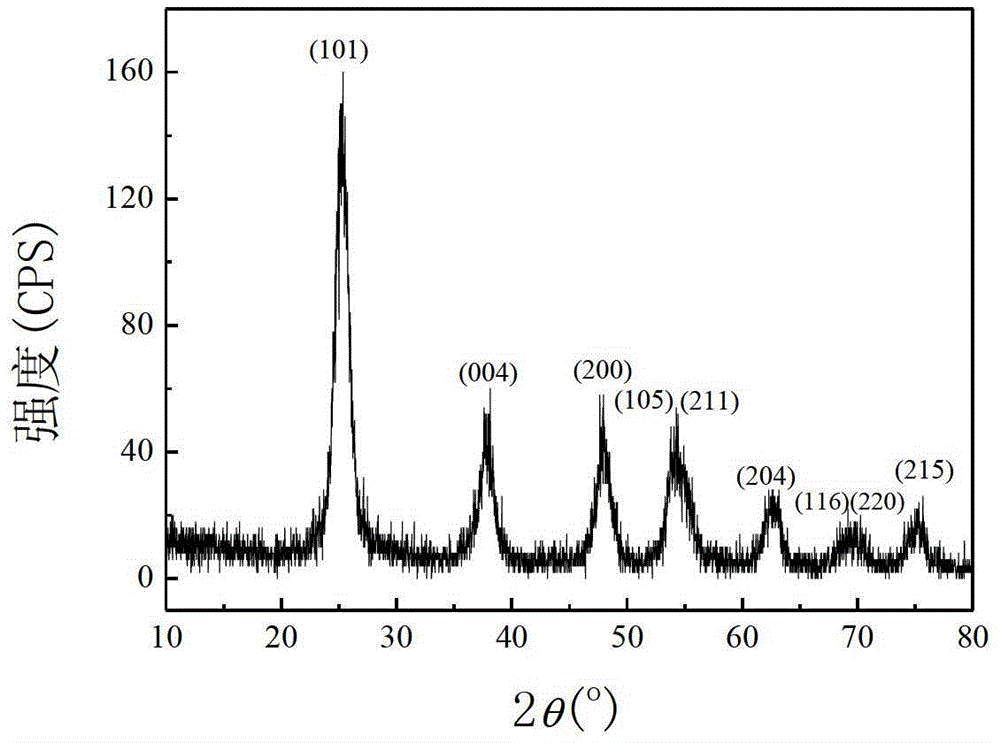

[0063] Weigh 2.0g of polyester fiber and 6.0g of titanium sulfate according to the mass ratio of 1:3, soak the polyester fiber in 5g / L sodium hydroxide solution, etch at 90°C for 20min, then dry it with 50°C anhydrous The ethanol solution was ultrasonically oscillated at 40KHz and 100W for 15min, and then washed repeatedly with deionized water, and the washed polyester fabric was dried at 70°C; the polyester fiber after etching treatment was weighed, and after etching treatment, The mass ratio of polyester fiber to titanium sulfate is 1:3, weigh 6g of titanium sulfate, weigh 10g of urea according to the mass ratio of titanium sulfate to urea of 3:5, and weigh 0.3g of silver nitrate according to 5% of the mass of titanium sulfate , measure 24g of deionized water according to the mass ratio of titanium sulfate to deionized water 1:4, measure 2.4g of polyethylene glycol according to 10% of the mass of deionized water, add polyethylene glycol to the deionized water, Under the co...

Embodiment 2

[0066] Weigh 2.0g of polyester fiber and 12.0g of titanium sulfate according to the mass ratio of 1:6, soak the polyester fiber in 20g / L sodium hydroxide solution, etch for 40min at 100°C, and use 70°C anhydrous The ethanol solution was ultrasonically oscillated at 40KHz and 100W for 30min, and then repeatedly washed with deionized water, and the cleaned polyester fabric was placed at 90°C for drying; The mass ratio of the polyester fiber to titanium sulfate is 1:6 to weigh 12g of titanium sulfate, 4g of urea is weighed according to the mass ratio of titanium sulfate to urea of 3:1, and 1.2g of chlorinated chloride is weighed according to 10% of the mass of titanium sulfate. For iron, measure 96 g of deionized water according to the mass ratio of titanium sulfate to deionized water of 1:8, and measure 19.2 g of polyethylene glycol according to 20% of the mass of deionized water, and add polyethylene glycol to the deionized water. , Under vigorous stirring conditions, titanium ...

Embodiment 3

[0069] Weigh 2.0g of polyester fiber and 8.0g of titanium sulfate according to the mass ratio of 1:4, soak the polyester fiber in 10g / L sodium hydroxide solution, etch for 30min at 100℃, use anhydrous at 60℃ The ethanol solution was ultrasonically oscillated for 20 minutes at 40KHz and 100W, and then repeatedly washed with deionized water. The cleaned polyester fabric was placed at 80°C for drying; The mass ratio of the polyester fiber to titanium sulfate is 1:4 to weigh 8g of titanium sulfate, 4g of urea is weighed according to the mass ratio of titanium sulfate to urea of 2:1, and 0.56g of nickel sulfate is weighed according to 7% of the mass of titanium sulfate , Measure 48g of deionized water according to the mass ratio of titanium sulfate to deionized water 1:6, and measure 7.2g of polyethylene glycol according to 15% of the mass of deionized water, add polyethylene glycol to deionized water, Under vigorous stirring conditions, titanium sulfate, urea and nickel sulfate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com